System for treating ballast water in ballast tanks

A ballast tank and ballast water technology, used in water treatment devices, natural water treatment, heating water/sewage treatment, etc., can solve the problems of capacity and performance limitations of ballast water pumps and piping systems, and achieve comprehensive treatment time. Optimal mixing process and corrosion protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

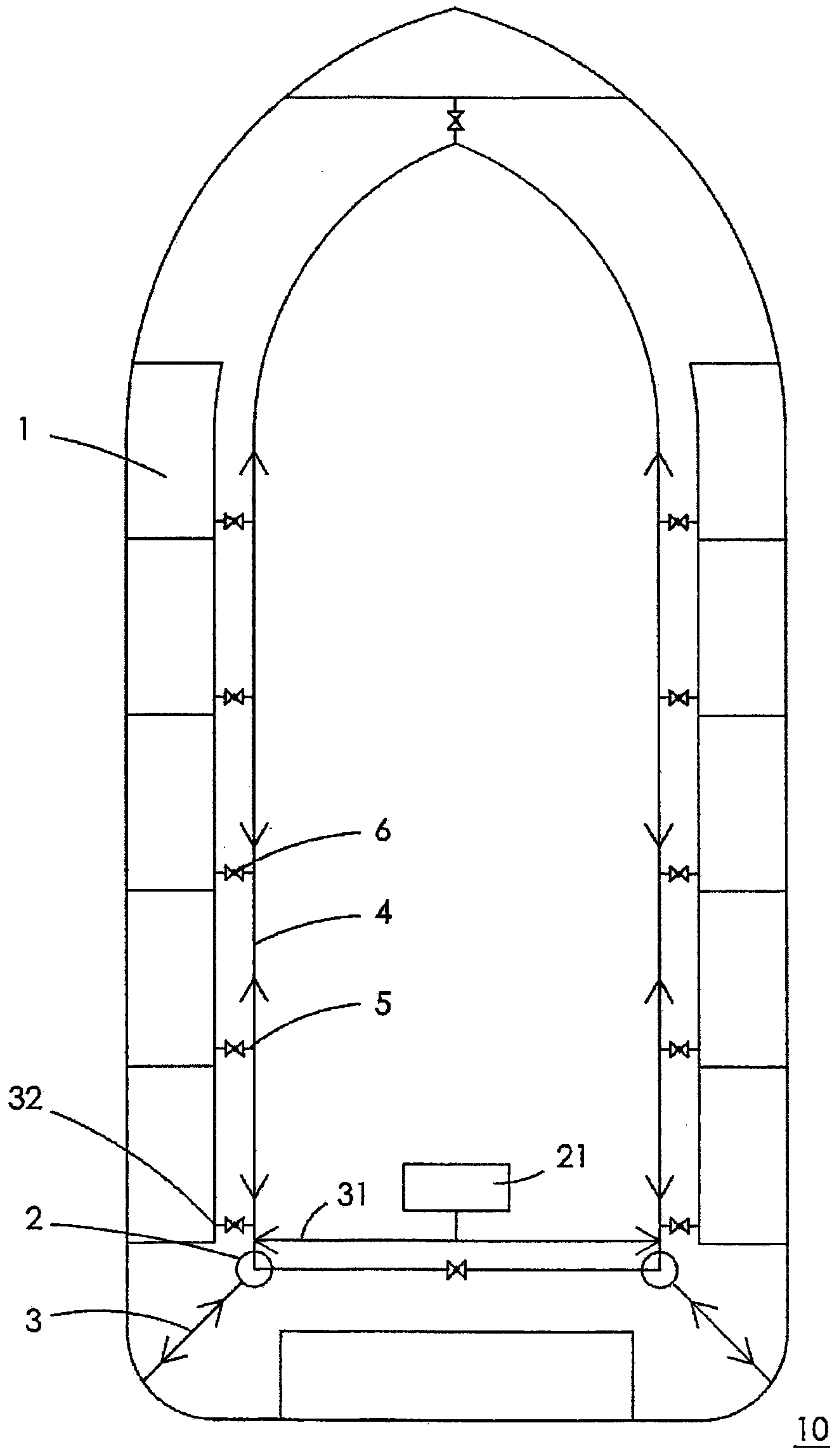

[0050] figure 1A system 10 is shown configured as a conventional piping and pumping system for circulating ballast water to the ballast tanks 1 on board the ship. Ballast tanks 1 are usually arranged along the periphery of the ship and each ballast tank 1 is provided with a ballast water distribution pipe 5 from the main supply line. The distribution pipe 5 is provided with an appropriate number of valves 6 .

[0051] The system 10 can be used to supply ballast water to the ballast tank and to discharge ballast water from the ballast tank 1 .

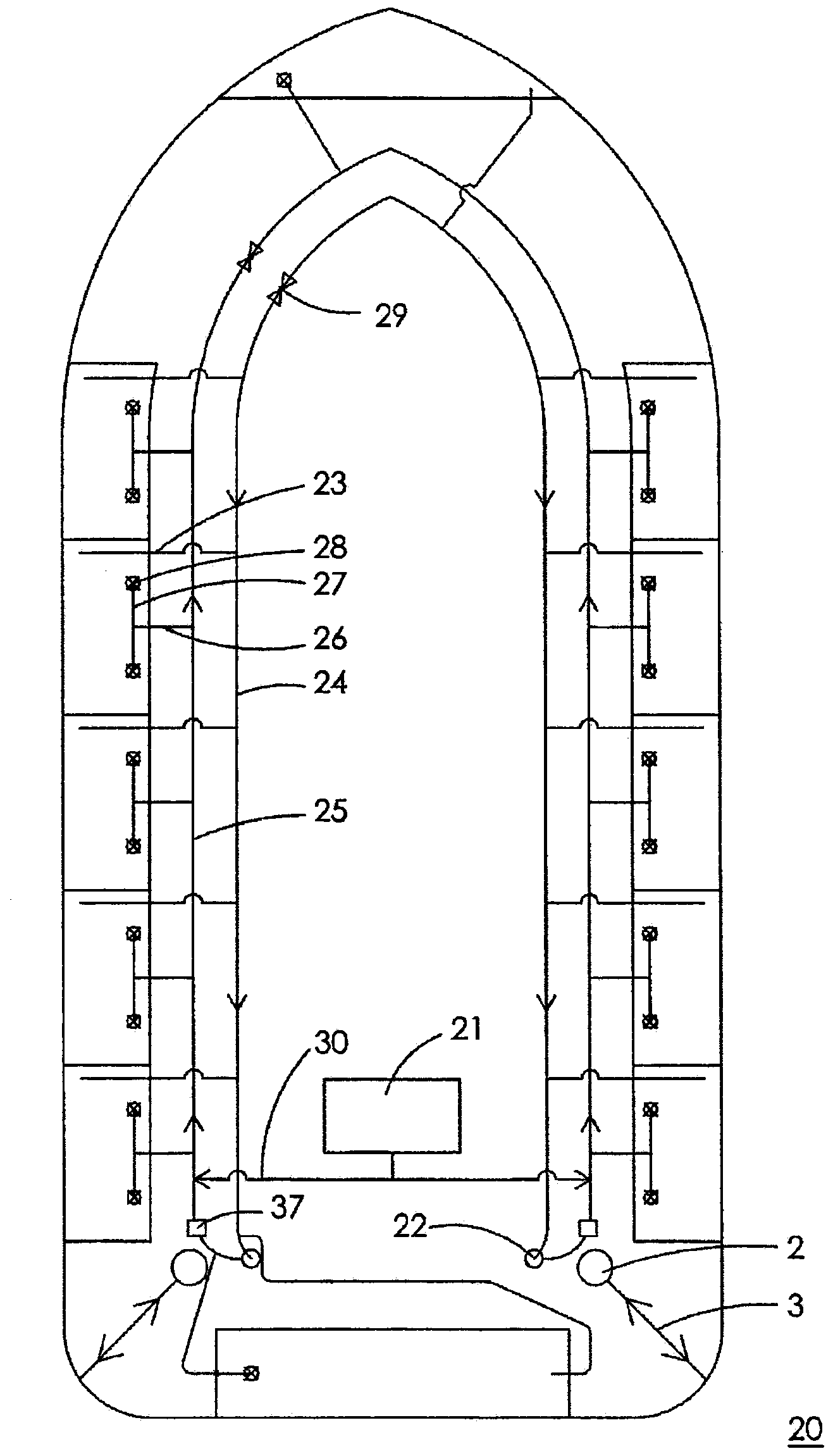

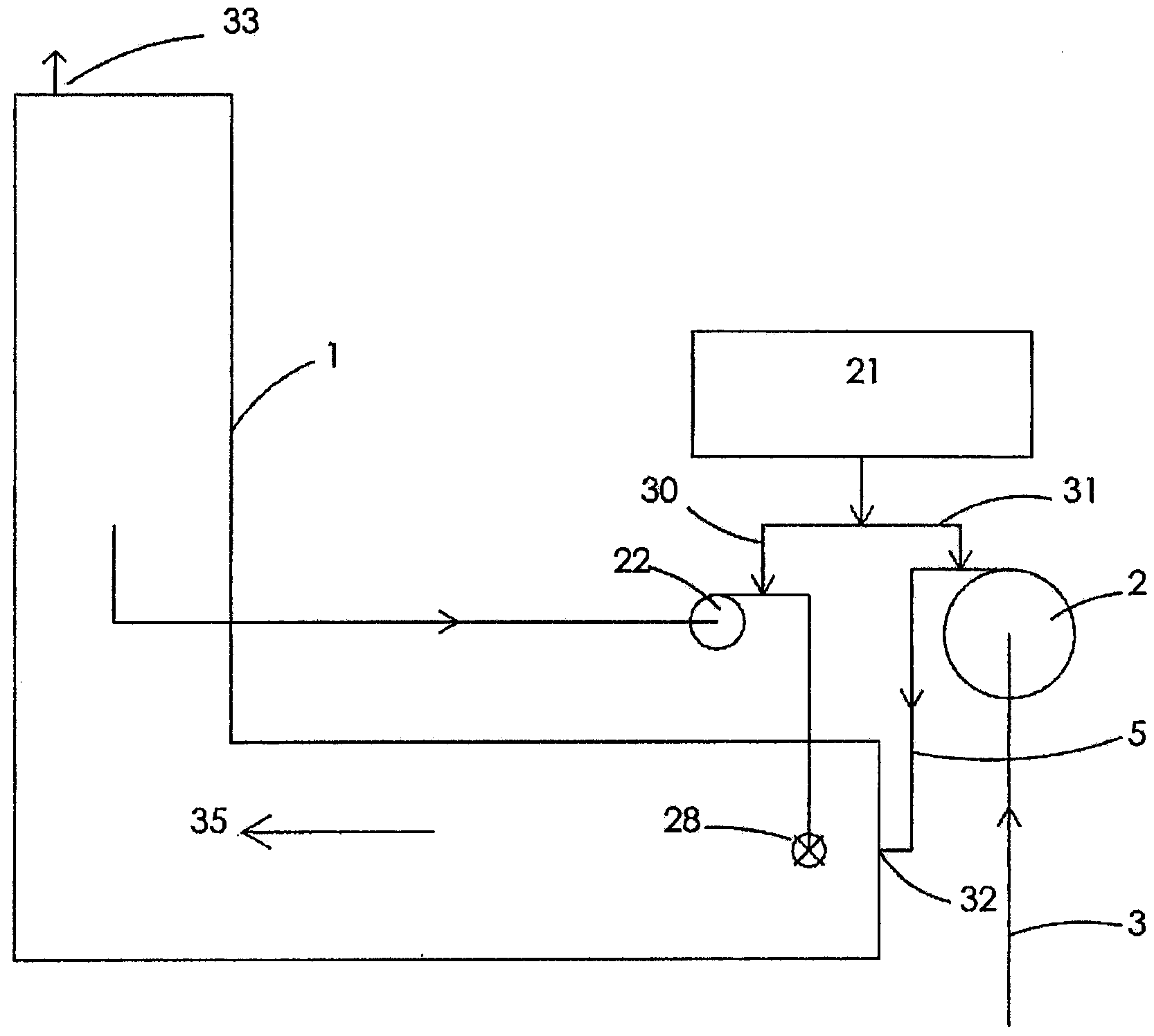

[0052] figure 2 An embodiment of the invention is shown in which the recirculation system 20 supplements figure 1 The conventional ballast water pumping system 10 described in . The recirculation system 20 is composed of a recirculation pump 22 and pipelines communicating with the ballast tank 1 and the nitrogen generator 21 .

[0053] The ballast water is pumped out of the ballast tank 1 by the recirculation pump 22 via the retur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com