Systems and methods for treating ballast water in ballast tanks

A ballast tank and ballast water technology, applied in chemical instruments and methods, water treatment devices, natural water treatment, etc., can solve problems such as capacity and performance limitations of ballast water pumps and piping systems, and achieve comprehensive treatment time and prevent Erosion, optimizing the effect of the mixing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

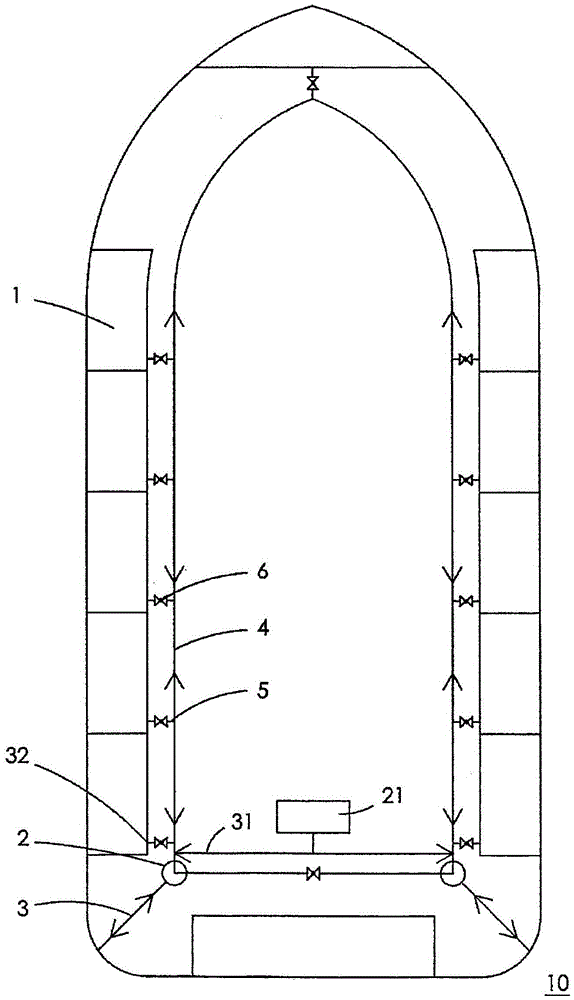

[0050] figure 1A system 10 is shown configured as a conventional piping and pumping system for circulating ballast water to ballast tanks 1 on board. Ballast tanks 1 are generally arranged along the periphery of the vessel, and each ballast tank 1 is provided with a ballast water distribution pipe 5 from the main supply line. The distribution pipe 5 is provided with an appropriate number of valves 6 .

[0051] The system 10 may be used to supply ballast water to and discharge ballast water from the ballast tank 1 .

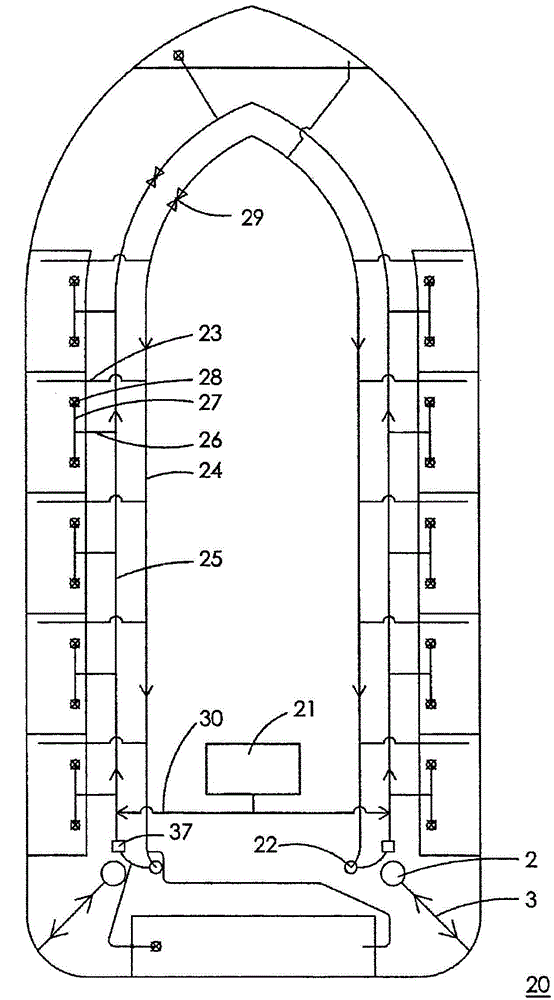

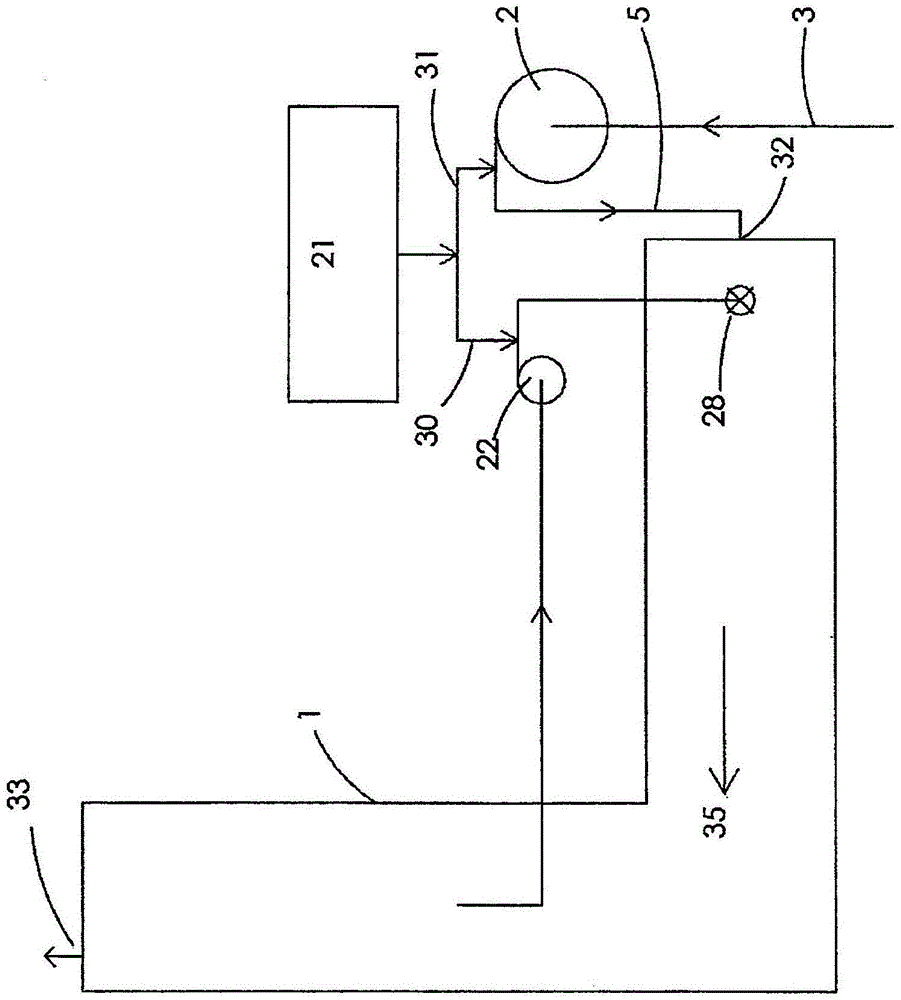

[0052] figure 2 An embodiment of the present invention is shown in which the recirculation system 20 supplements figure 1 A conventional ballast water pumping system 10 as described in . The recirculation system 20 consists of a recirculation pump 22 and pipes communicating with the ballast tank 1 and the nitrogen generator 21 .

[0053] Ballast water is pumped out of ballast tank 1 by recirculation pump 22 via return pipe 23 to return pipe 24 and returned t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com