Brake discs for land vehicles and land vehicles in particular with such brake discs

A technology for brake discs and commercial vehicles, applied in the direction of brake discs, etc., can solve the problems of increased weight, limited space, reinforcement of brake discs, etc., and achieve the effect of preventing relative movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

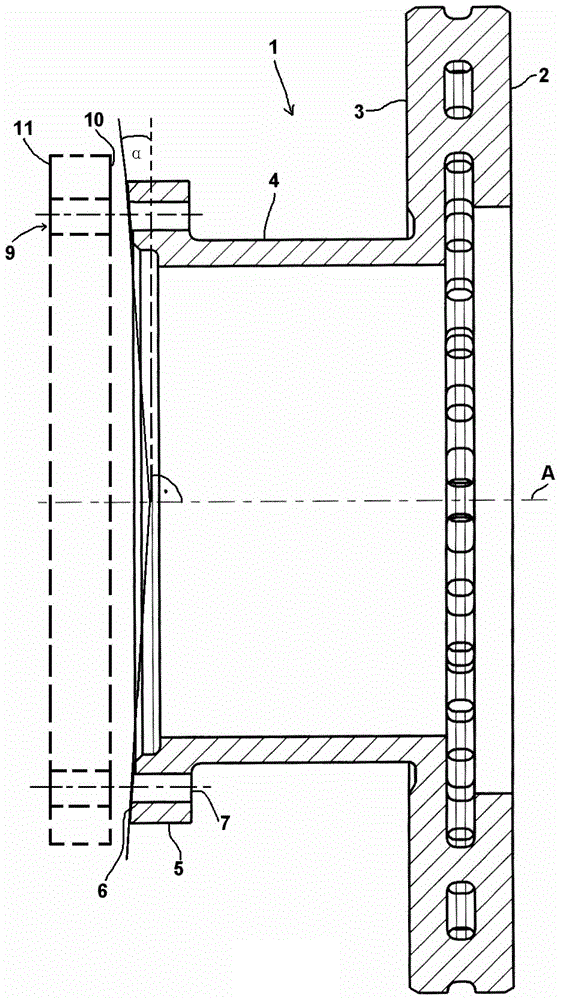

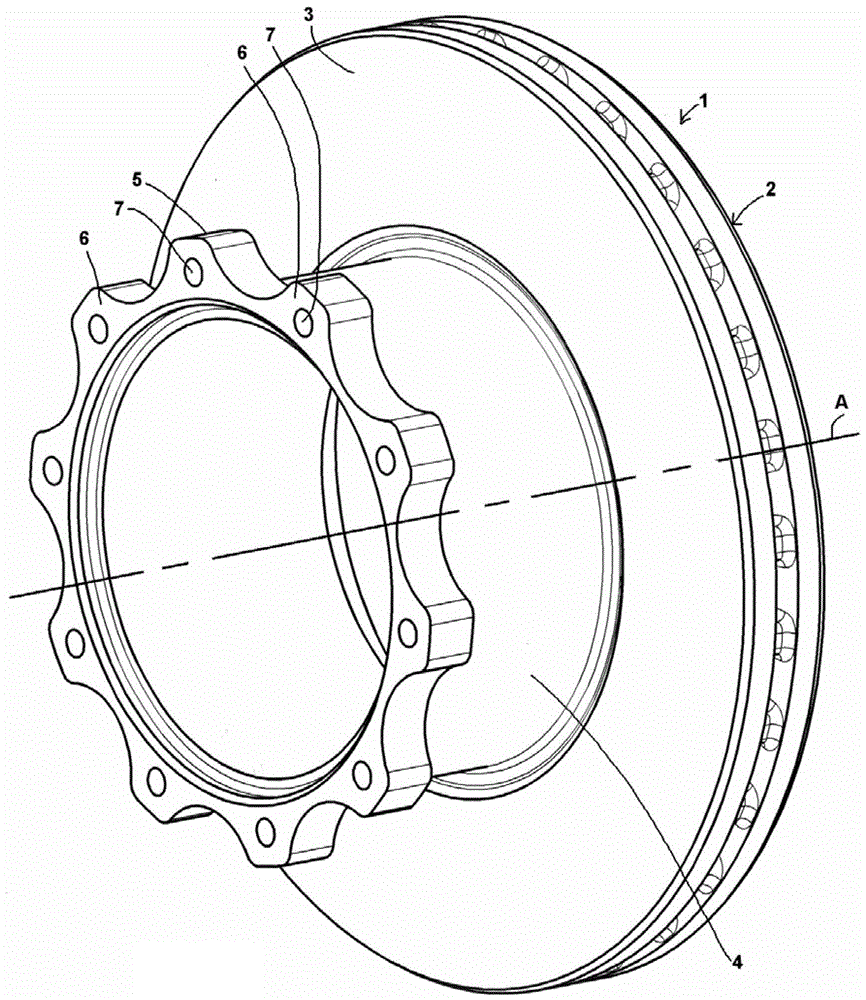

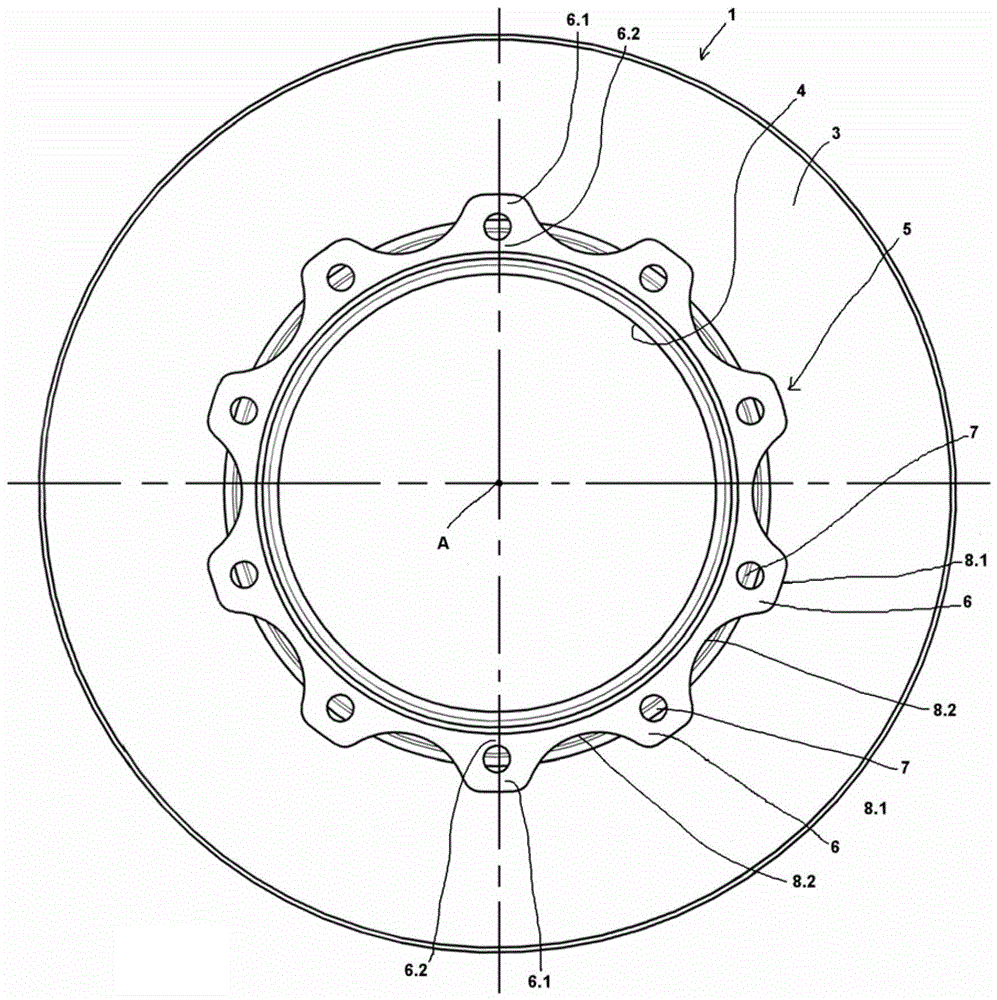

[0032] The brake disk shown in the figures is designated with the reference numeral 1 throughout. The brake disc comprises two friction rings, which are connected to each other, for example by webs, cross pins, cross beams or other means, while forming cooling channels, and the friction rings also have two friction surfaces 2, 3 , which are pressed together with the brake pads of the disc brake not shown in the drawing during braking. The axis of rotation of the brake disc 1 is marked with A.

[0033] The brake disk 1 has a disk sleeve 4 which is formed in one piece, for example, with a friction ring which contains the friction surface 3 .

[0034] The disc drum 4 has at one end thereof a disc flange 5 with a flange face 6 integral therewith and extending radially outwards. Disc flange 5 in image 3 has a corrugated outer contour, which forms protrusions 8.1 at its crests and grooves 8.2 at its troughs. The crest or protrusion 8.1 has at least one through-opening 7.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com