Manufacturing process of business suit collar

A manufacturing process and collar technology, which is applied in the field of suit collars, can solve problems such as warped collar angles, damage to the texture of fabric fibers, and empty lapels, etc., to achieve the effects of reducing production costs, saving energy consumption, and having a suitable curvature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Examples such as Figure 1-7 Shown, a kind of manufacturing process of suit collar comprises the steps:

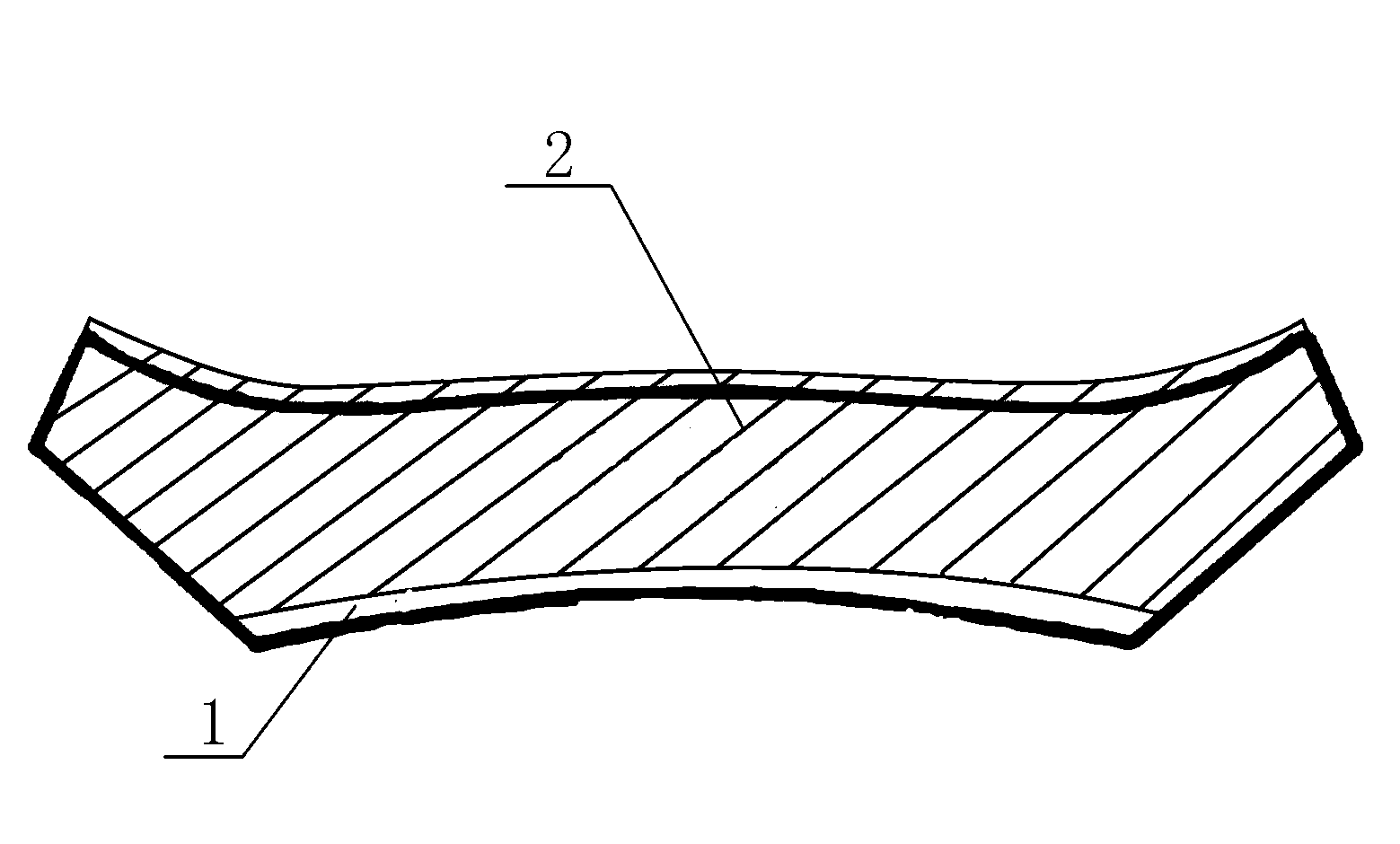

[0039] a. Stack the collar backing 2 and the collar backing 1. When stacked, the collar backing 2 should be 0.3cm smaller than the collar bottom 1's periphery, and the outer neckline needs to be 0.1cm wider than the neck stop.

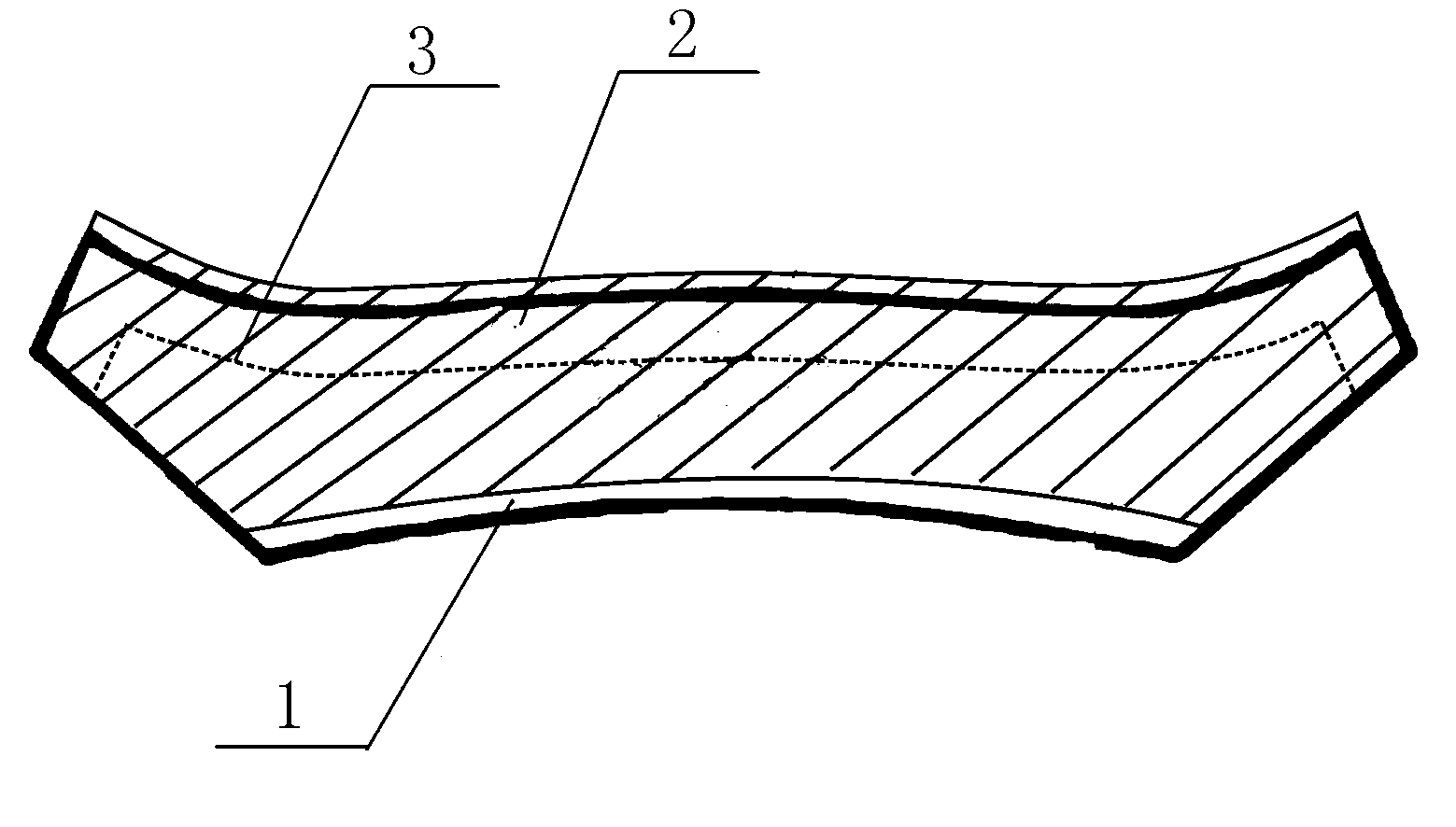

[0040] b. Tick topstitch 3 at the outer neckline 1.5cm away from collar bottom woolen 1 and fix underlayment 2 and collar bottom woolen 1. Use an iron to stick within topstitch 3, and open the outer neckline without gluing to prepare for stuffing collar surface 9.

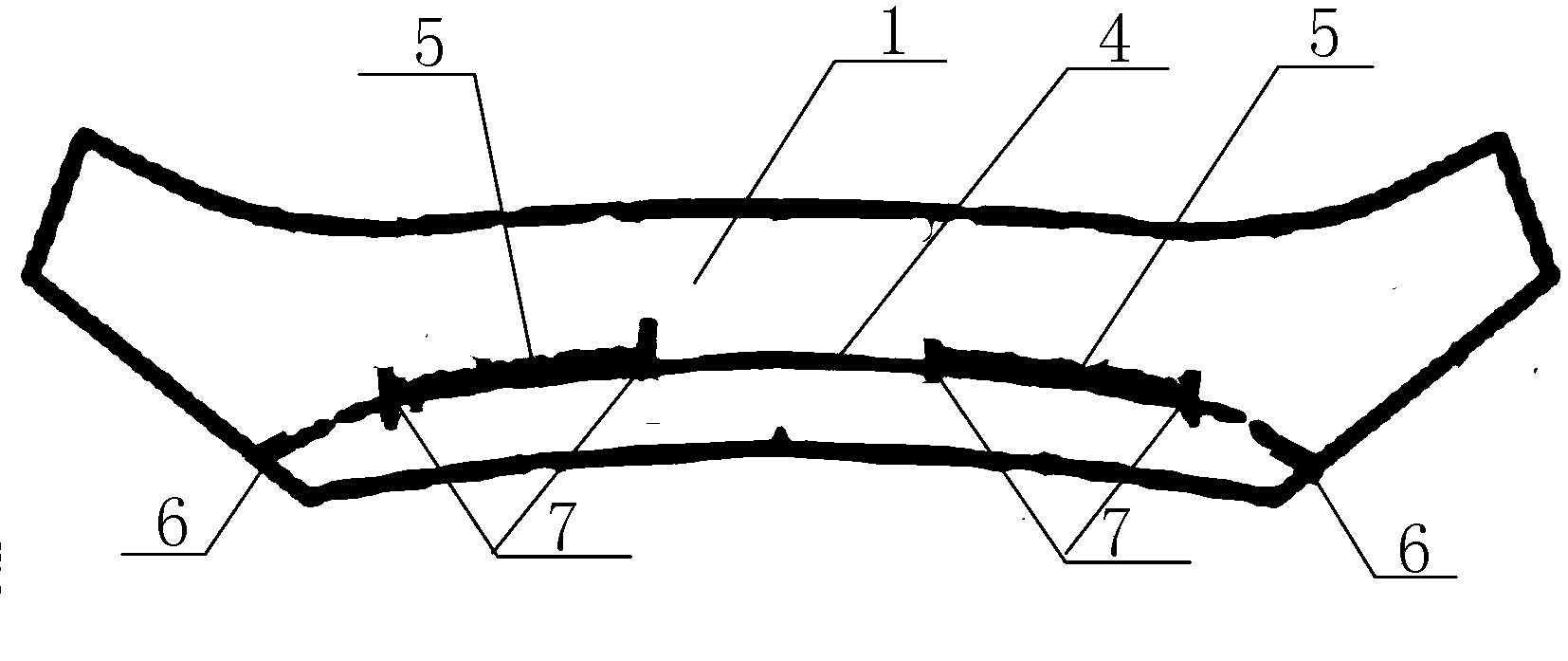

[0041] c. Pull the collar seat line 4 on the collar base 1, along the collar seat line 4 scissors eye 7, pull the cotton cloth leash 5 between the knife eyes 7 along the collar seat line 4, press the knife eye 7 position to start the shoulder seam 0.4cm at the center, make a 1cm notch 6 at both ends of the neckline.

[0042] d. Collar stitching, set the collar 8 along the colla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com