Dust collector capable of automatically clearing blocking dust in Hepa filter

An automatic cleaning and filter technology, applied in the direction of cleaning filter devices, etc., can solve the problems of inconvenience, trouble and inefficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

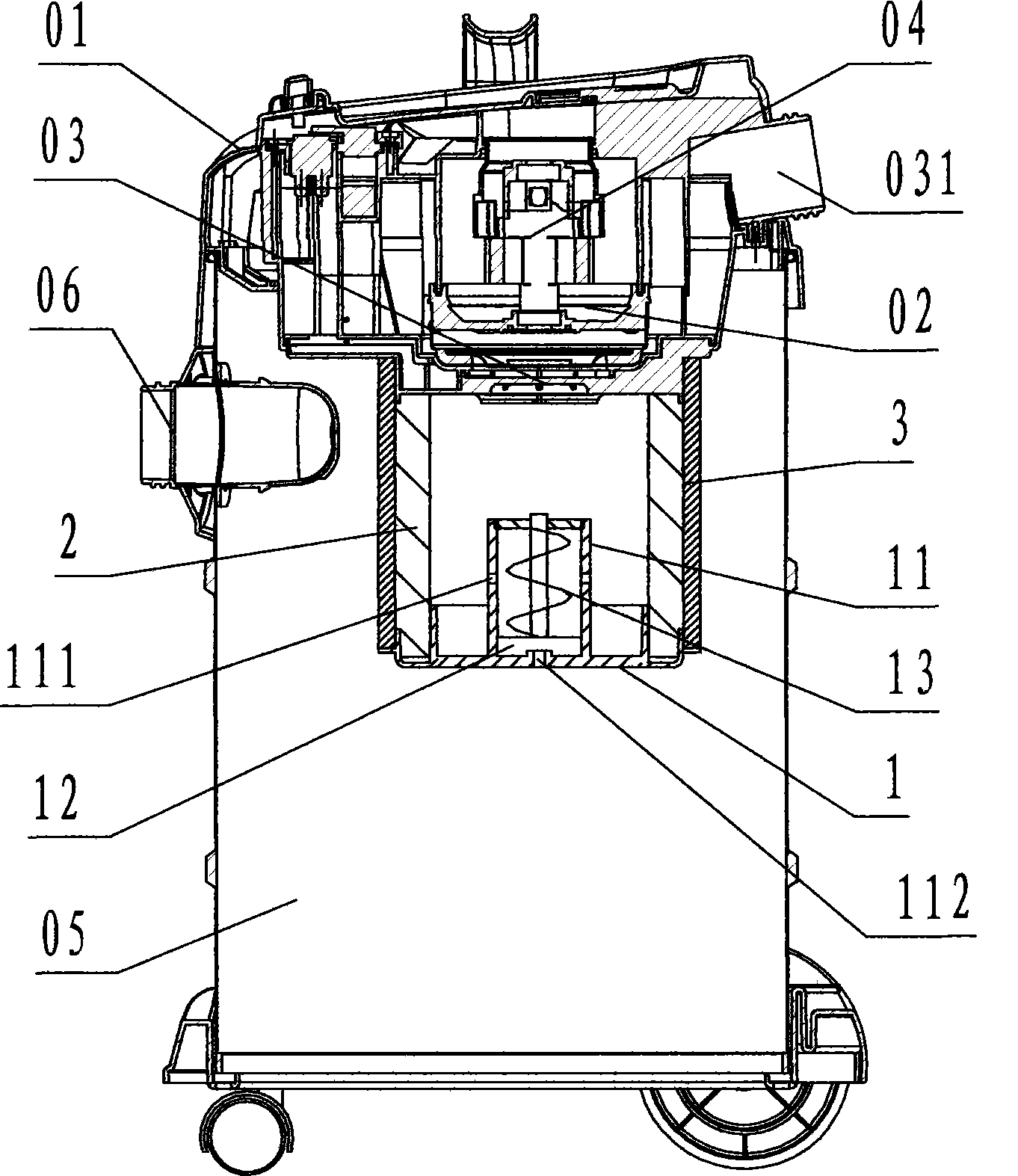

[0016] refer to figure 1 , a vacuum cleaner capable of automatically removing the dust blockage of the Hypa filter according to the present invention, comprising a connecting cover 1, a bracket 2, and a Hypa filter 3, wherein: the connecting cover 1 is a disc-shaped steel member, connected The upper center of the cover 1 is provided with a piston cylinder 11 protruding upwards, thin-walled and hollow, and has a cylindrical lumen shape. The upper pipe wall of the piston cylinder 11 is provided with a number of circular through holes called short-circuit holes 111. The center of the bottom surface of the cylinder 11 is provided with a circular through hole called the valve hole 112, and the center of the top of the piston cylinder 11 is provided with a circular through hole called the guide hole;

[0017] A cylindrical steel piston 12 is slidably provided in the inner cavity of the piston barrel 11, and a cylindrical guide rod protruding upwards is provided at the center of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com