Suspension arm type odontoid guide needle sighting device

A cantilever type, aiming technology, applied in medical science, surgery and other directions, can solve the problems of internal fixation screw offset, cannot be connected in series, affecting the operation effect, etc., and achieves the effect of reliable fixation, easy adjustment and accurate aiming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

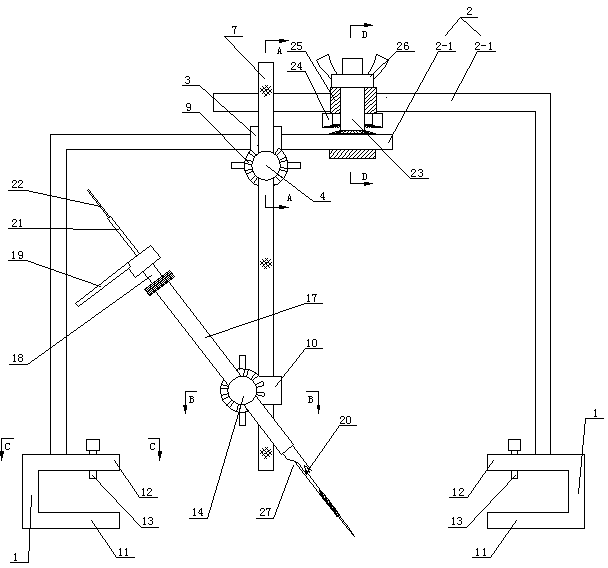

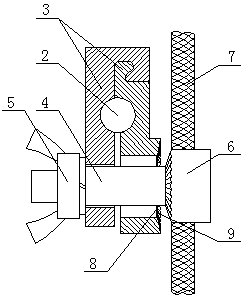

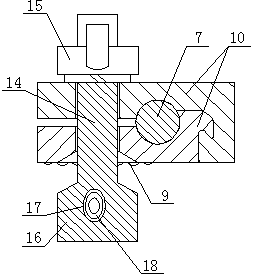

[0019] Referring to the accompanying drawings, the cantilever type denticule guide pin collimator includes two lower connecting seats 1 oppositely arranged, and the two lower connecting seats 1 respectively have an upper pressing plate 11 and a lower supporting plate 12 which are parallel up and down and arranged correspondingly. A plurality of jacking bolts 13 are screwed on the plate 11, and a door-shaped cantilever 2 with a circular cross section is fixedly connected between the two opposite upper pressing plates 11, and the door-shaped cantilever 2 is respectively fixed on the two upper pressing The two sections of L-shaped cantilever 2-1 are composed of two sections of L-shaped cantilevers 2-1 on the back plate 11. The opposite extending ends of the two L-shaped cantilevers 2-1 are connected by sliding and rotating connecting blocks. The mutual displacement of -1 controls the length of the gate-shaped cantilever 2, and any section of the L-shaped cantilever 2-1 can be rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com