Automatic feeding device of red flushing furnace

A technology of automatic feeding and red punching furnace, which is applied in the field of red punching furnace and automatic feeding device of red punching furnace, can solve the problems of a large number of manual labor, self-safety threats, high labor intensity, etc., to reduce the probability of unqualified products, The effect of long service life and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

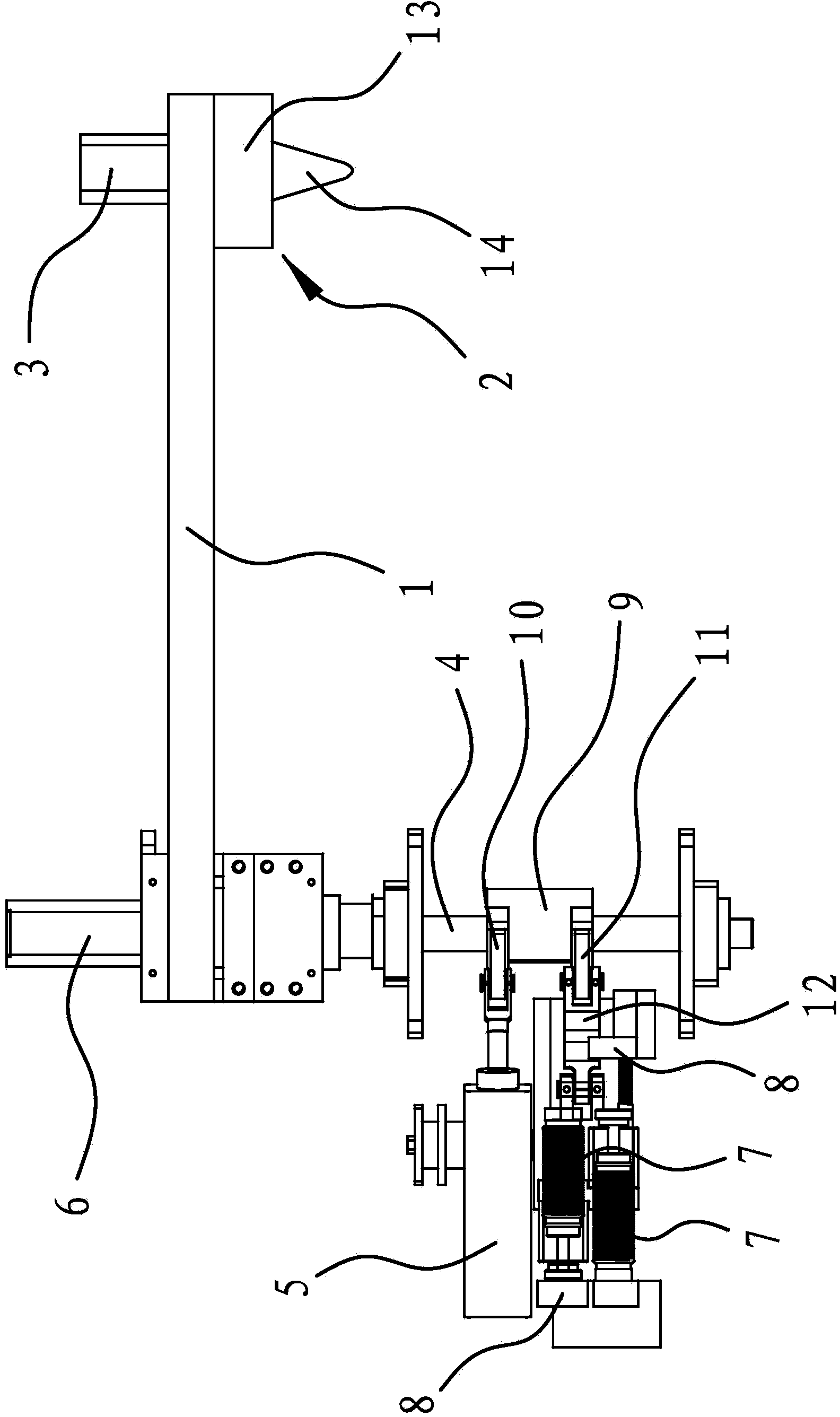

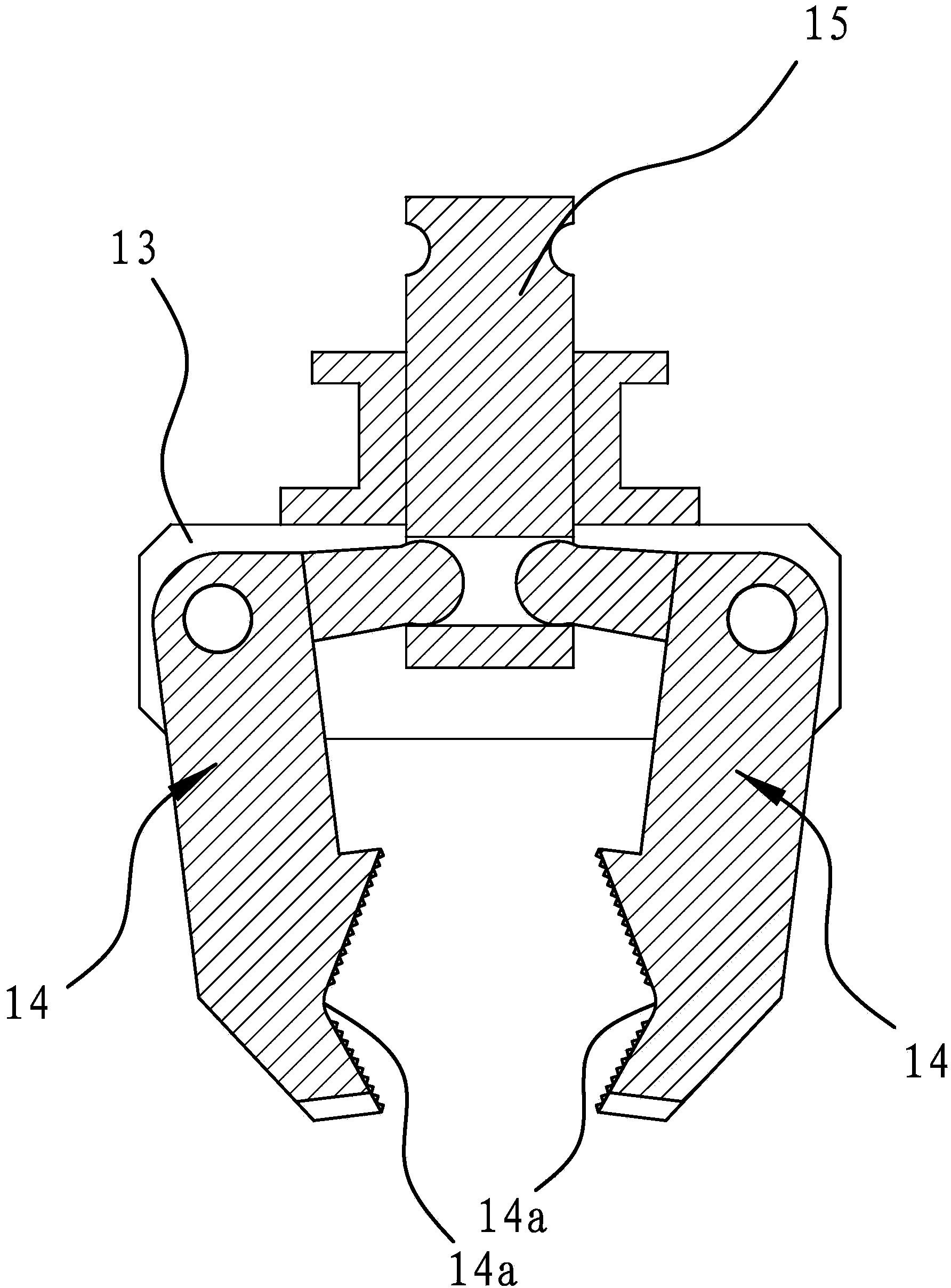

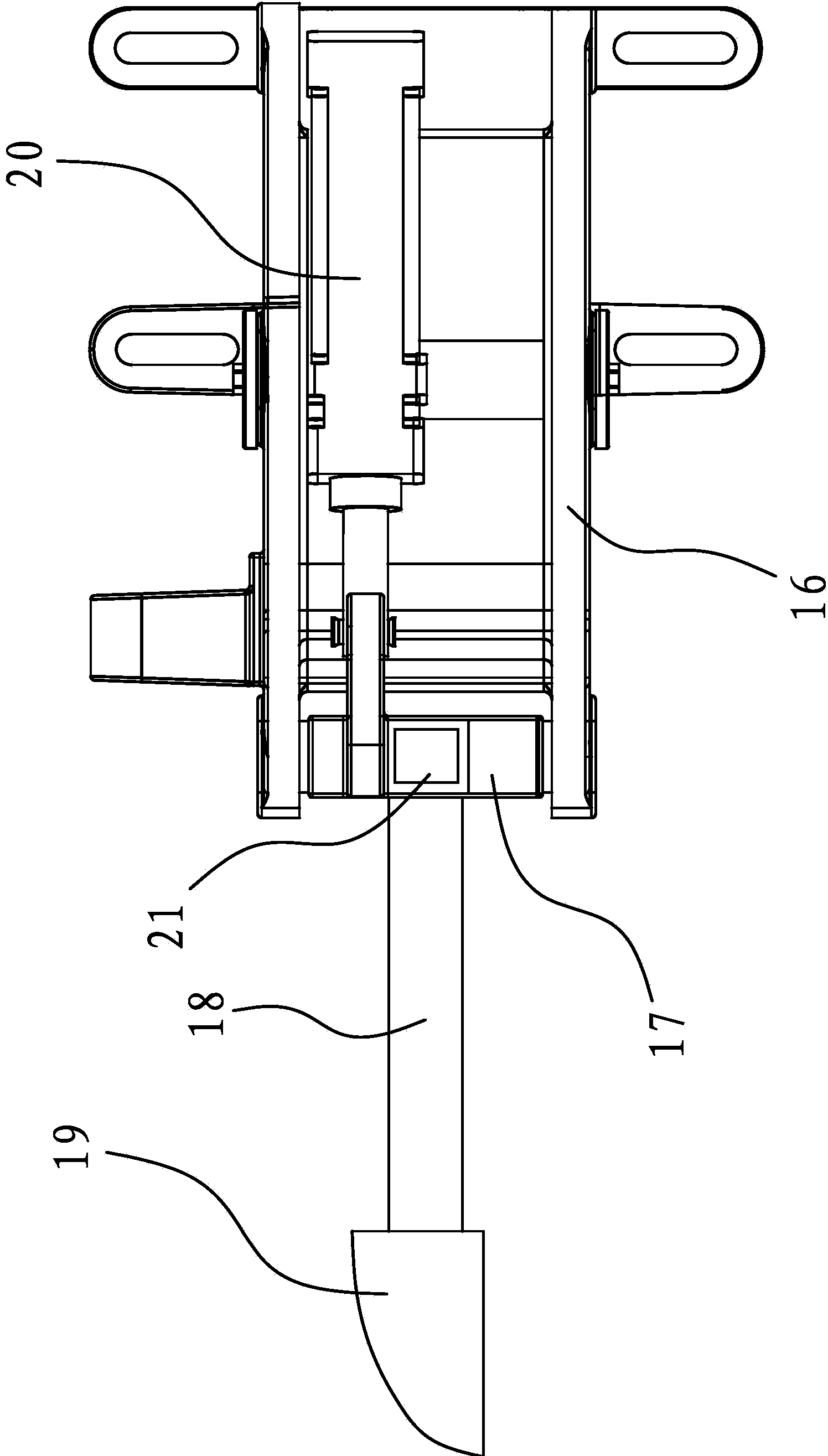

[0029]The automatic feeding device of this red punching furnace includes a controller, a material selection mechanism, a feeding manipulator and a material unloading manipulator. The entrance of the material selection mechanism is set opposite to the workpiece output port of the heating furnace, and the feeding manipulator can automatically select the material outlet of the material selection mechanism. Grab the workpiece at the red punching station and send it to the red punching station, and the unloading manipulator can catch the processed workpiece from the red punching station and transport it to the unloading station. The controller can automatically control the material selection mechanism, the feeding manipulator an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com