Heavy-duty die-forging hydraulic press

A hydraulic press and die forging technology, applied in the direction of swaging presses, upsetting presses, etc., can solve the problems of workpiece quality and production efficiency, the workpiece cannot meet the requirements of use, shorten the service life of hydraulic presses, etc. Production efficiency, prolong the service life of equipment, prolong the service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0027] In order to further understand the content, features and effects of the present invention, the following embodiments are given as examples, and detailed descriptions are as follows with accompanying drawings:

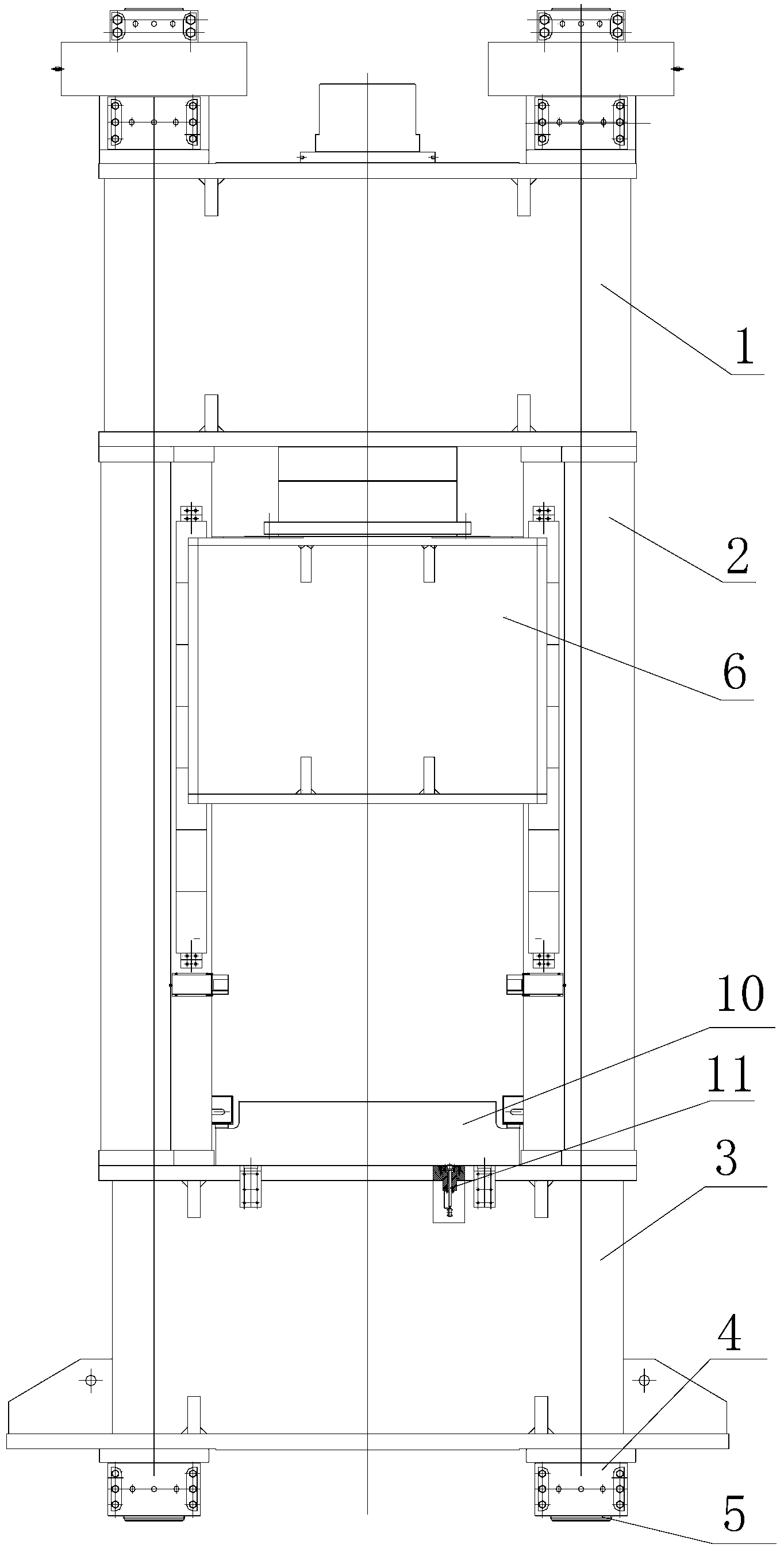

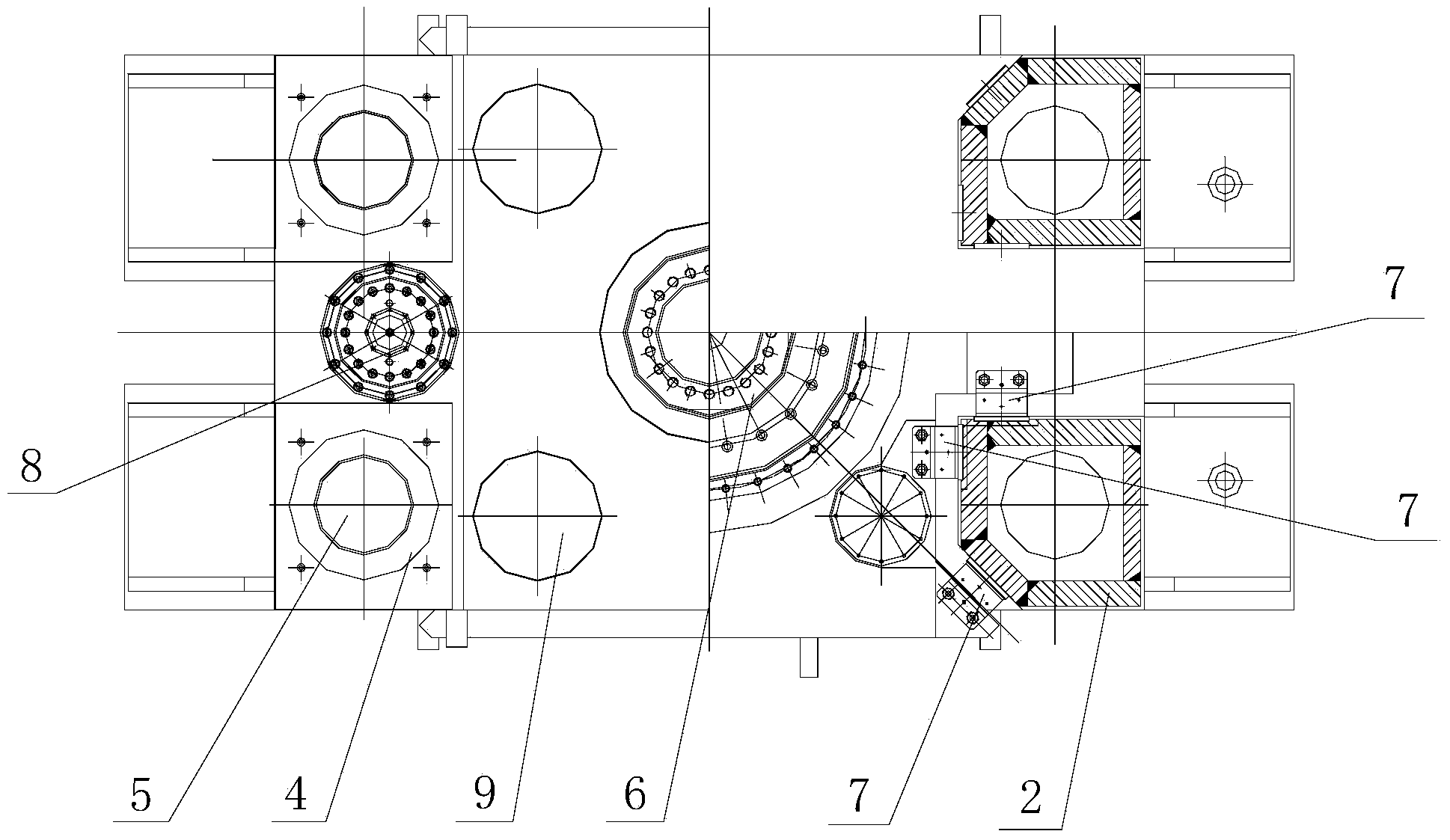

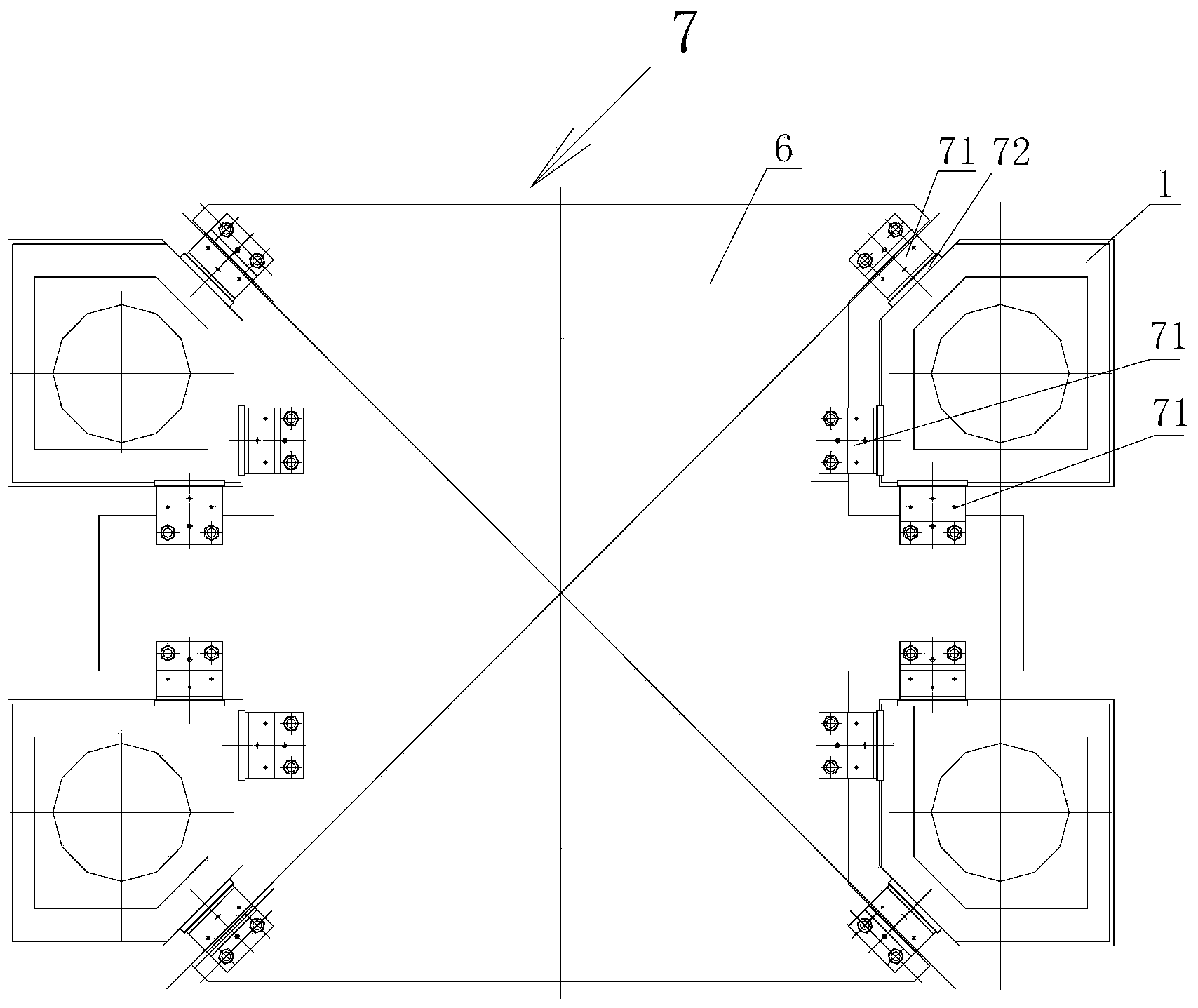

[0028] See Figure 1-Figure 5 , Heavy-duty die forging hydraulic press, including upper beam 1, lower beam 3, four uprights 2, tie rod 5 and lock nut 4 pre-tightened to form a closed combined frame fuselage, the upper beam is fixedly equipped with a cylinder block 6 , The side cylinder 9 and the return cylinder 8, the other end of the side cylinder and the return cylinder are connected with a cylinder sliding block, a movable worktable 10 is provided on the lower cross beam, and the cylinder sliding block and the four uprights are provided with mutually matching The guide device 7 includes a guide rail assembly 71 arranged at the four corners of the sliding block with a cylinder, and a fixed guide plate 72 fixedly mounted on the side of the four vertical columns of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com