High-speed fine press

A press, high-speed technology, applied in the direction of presses, stamping machines, manufacturing tools, etc., can solve the problems of weak anti-eccentric load ability, high requirements for guide rail guidance accuracy and stiffness, etc., to reduce inertial force and improve deflection resistance The effect of load capacity and force reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

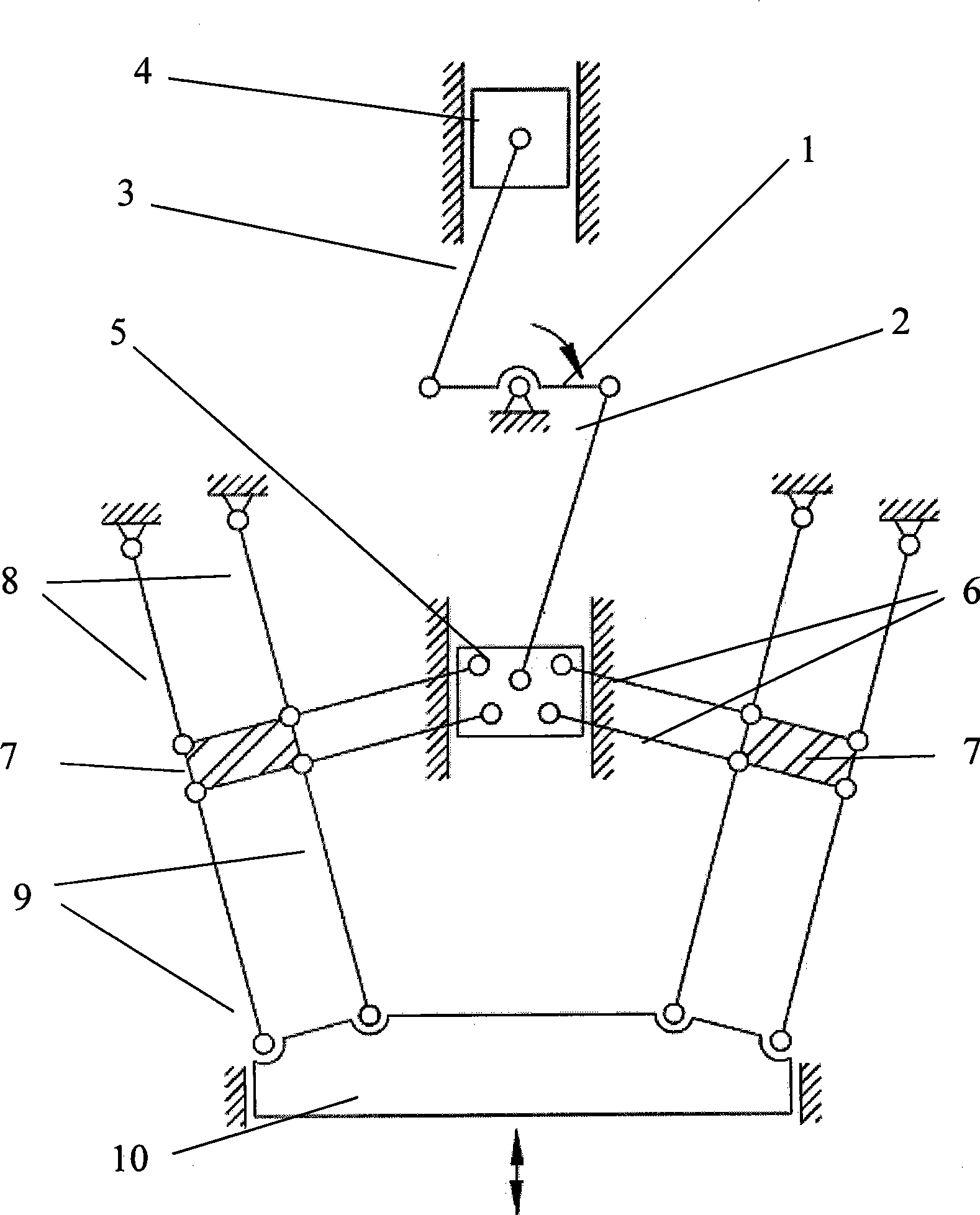

[0019] In order to obtain a good inertial force balance system, the high-speed precision press of the present invention adopts a combined balance scheme of a multi-bar balance mechanism and an auxiliary slide block arranged in the opposite direction. The crank drives the slider to reciprocate through the connecting rod. In order to balance the inertia force of the crank and the slider, the auxiliary slider and the auxiliary connecting rod are arranged in the opposite direction. In addition, two multi-rod branch chains are symmetrically arranged between the stamping slider and the bed. These two multi-rod branch chains are composed of two parallelogram mechanisms connected in series. The movement characteristics of the connecting rods of the parallelogram mechanism make the stamping slide The posture between the block and the bed remains unchanged. The reciprocating sliding block pushes the rods of the parallelogram mechanism to swing back and forth to both sides through two eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com