Large-tonnage gantry frame type oil press

A technology of gantry frame and hydraulic press, which is applied in the field of hydraulic machinery, can solve problems such as poor anti-eccentric load capacity, and achieve the effects of ensuring anti-eccentric load capacity, improving controllability, and improving anti-eccentric load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

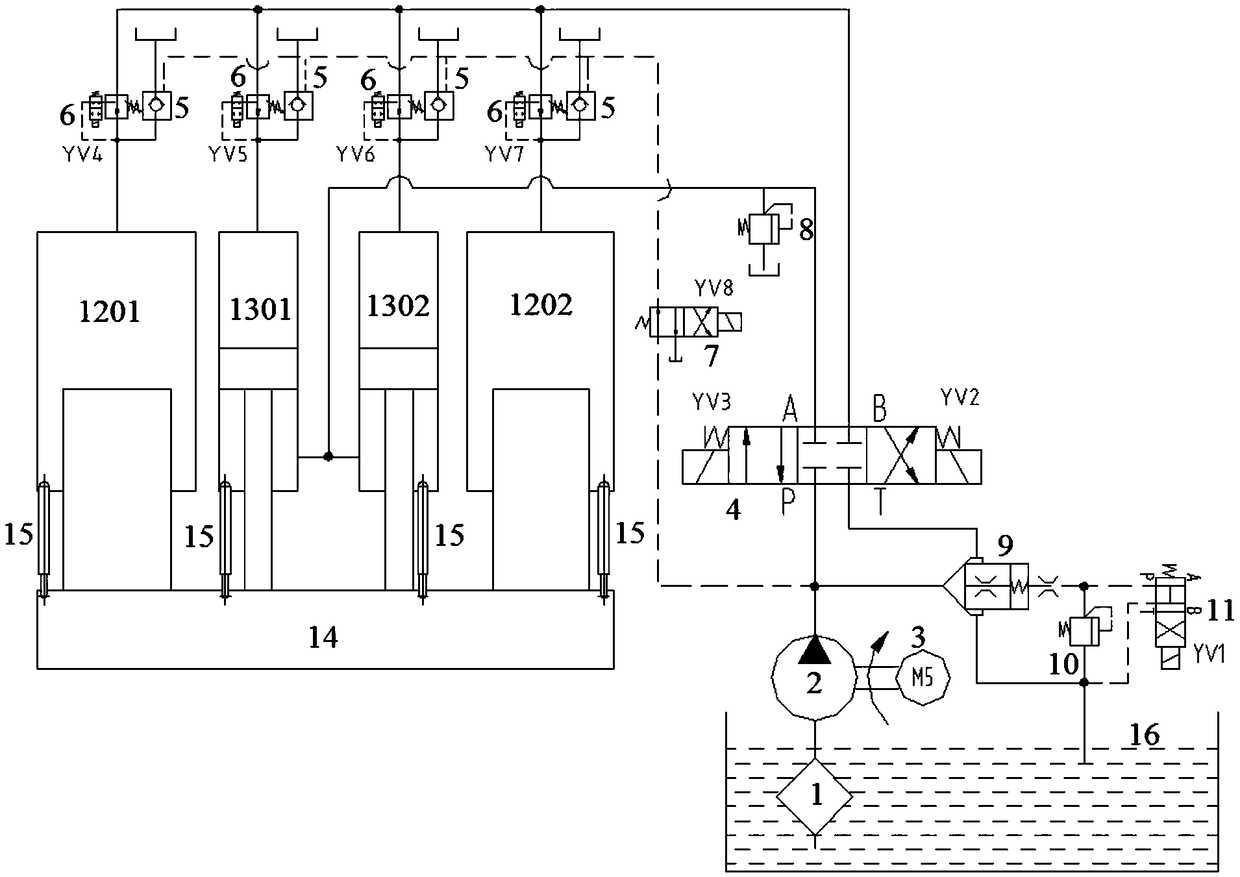

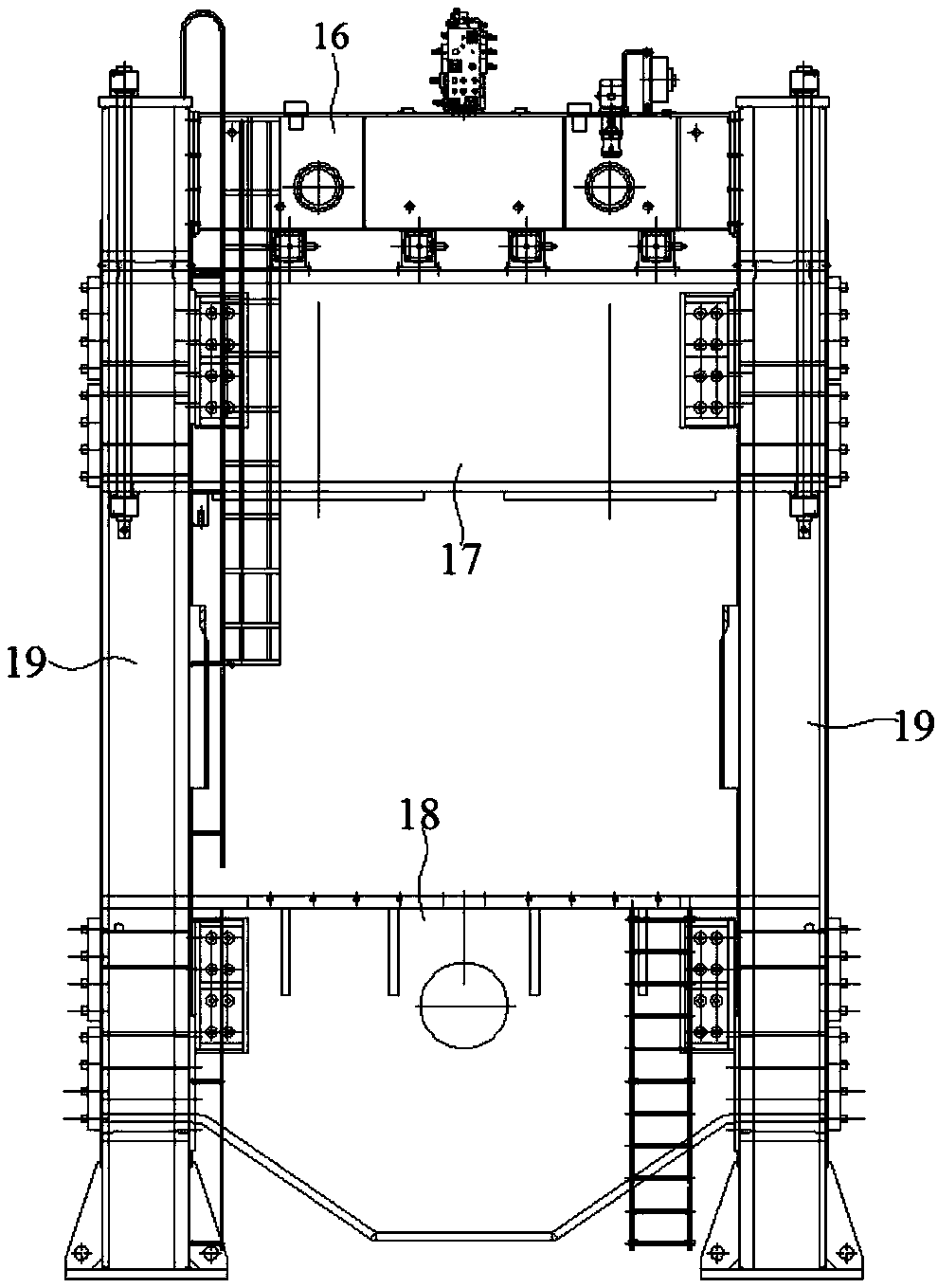

[0044] A large tonnage gantry frame hydraulic press in this embodiment includes left and right columns 19, an upper beam 17, a workbench 18 and a hydraulic system, and the left and right columns 19, upper beam 17 and workbench 18 are assembled to form the overall frame of the hydraulic press ,Such as figure 1 As shown, the hydraulic system includes an oil cylinder, an oil pump 2, an oil tank 16 and a three-position four-way valve 4. The oil cylinder includes a first master cylinder 1202, a second master cylinder 1202, a first auxiliary cylinder 1301 and a second auxiliary cylinder. Oil cylinder 1302, wherein the oil pump 2 is connected to the motor 3 for driving, and its oil inlet is connected to the oil tank 16 through the oil filter 1, and its oil outlet is connected to the P port of the three-position four-way valve 4, and the three-position four-way The A port of the valve 4 is connected with the lower cavity of the first auxiliary oil cylinder 1301 and the second auxiliar...

Embodiment 2

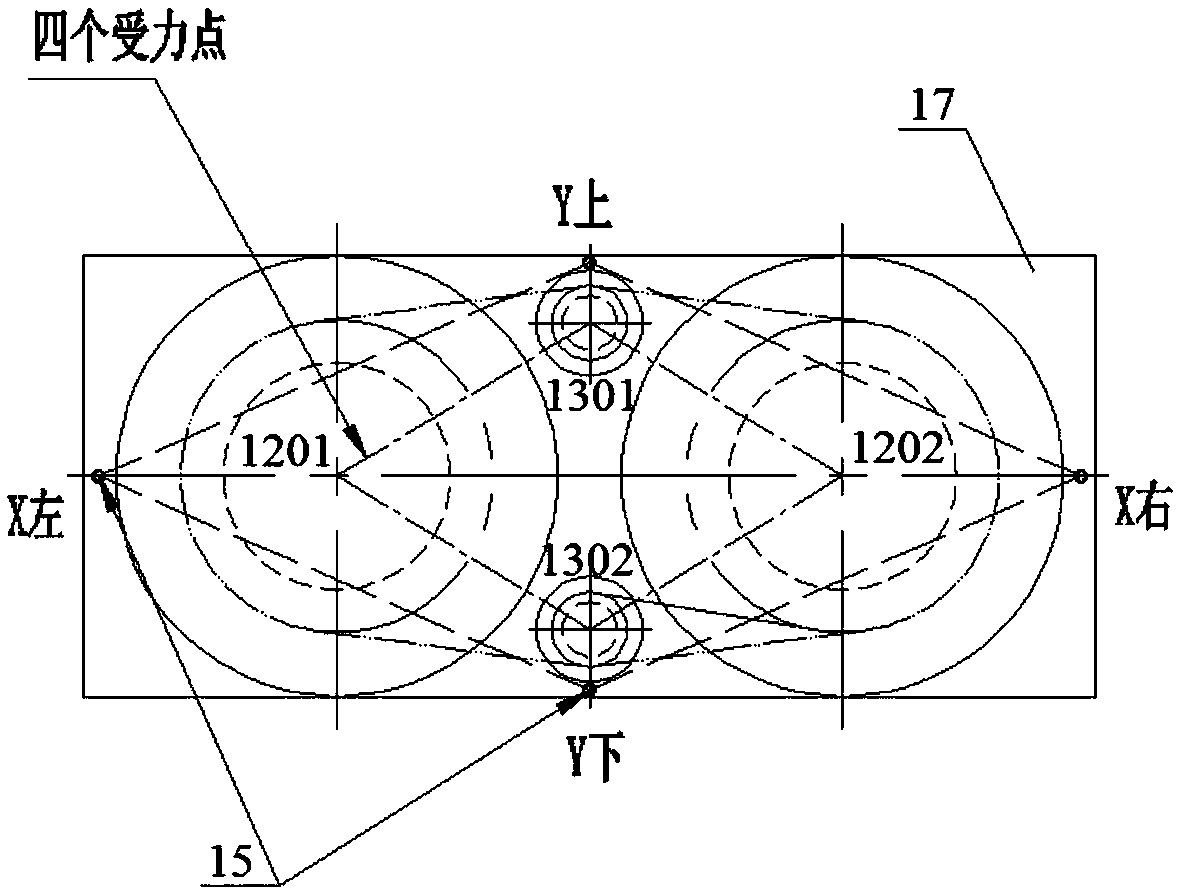

[0047] A kind of large-tonnage gantry frame type hydraulic press of this embodiment, its structure is basically the same as embodiment 1, and its difference mainly lies in: as figure 2 As shown, the first master oil cylinder 1202, the second master oil cylinder 1202, the first auxiliary oil cylinder 1301 and the second auxiliary oil cylinder 1302 are all installed on the upper beam 17 and distributed in a staggered manner according to a diamond structure, and the first auxiliary oil cylinder 1301 and the second auxiliary oil cylinder 1301 The second auxiliary oil cylinder 1302 is located on the vertical line connecting the first master oil cylinder 1202 and the second master oil cylinder 1202 . In this embodiment, the distribution of the oil cylinders is optimized and combined with the adjustment of the hydraulic system, so as to further ensure the anti-eccentric load capacity of the hydraulic press. At the same time, due to the round shape of the oil cylinder and the small i...

Embodiment 3

[0050] A large-tonnage gantry frame hydraulic press in this embodiment has the same structure as that in Embodiment 2. When the hydraulic press works on the "left" side of the equipment, its specific control process is as follows:

[0051] Quick down: YV1 of the electromagnetic overflow valve, YV2 of the three-position four-way valve 4 (three-position four-way electro-hydraulic directional valve), YV8 of the two-position four-way valve 7 and YV4, YV5, YV6 of the electromagnetic pressure reducing valve 6, YV7 is powered on, at this time the oil pump motor 3 drives the oil pump 2 to absorb oil from the oil tank 16 through the oil filter 1, and then passes through the three-position four-way valve 4 to the upper cavity of the four oil cylinders, and the other control oil path passes through the two-position four-way valve 7 (Two-position four-way reversing valve) is directly connected to the control ports of the four hydraulic control check valves 5, and the hydraulic control chec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com