Dual-cylinder dual-frame plate-and-frame hydraulic press with large table surface

A double-frame, plate-and-frame technology, which is applied to the driving devices of stamping machines, presses, forging presses, etc., can solve the problem of parallelism of the working stroke of the press and the parallelism of the slider table that cannot meet the requirements of large-scale and high-standard plate heat exchangers. Poor, unable to meet the quality requirements of large-scale plate manufacturing, to achieve the effect of shortening the production cycle, eliminating plane deformation, and improving operating accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

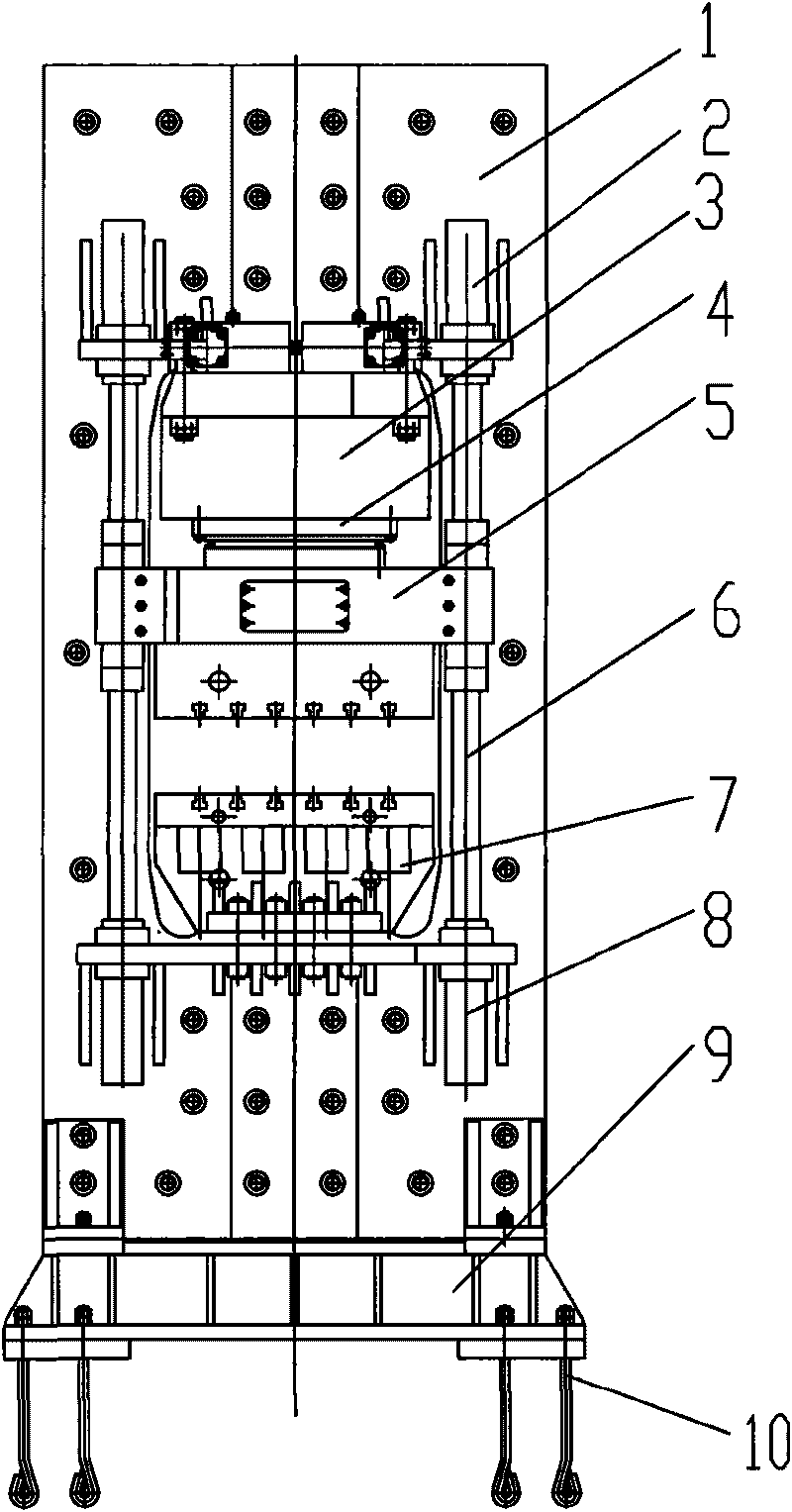

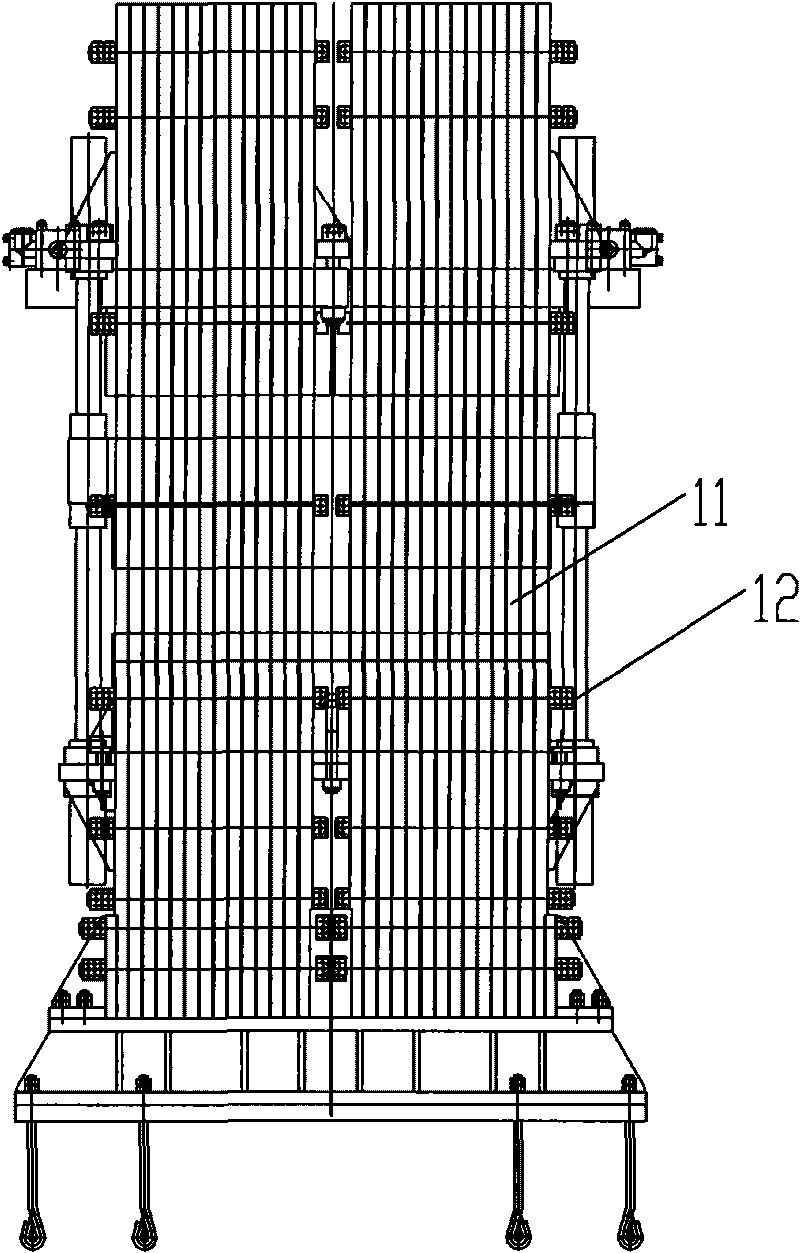

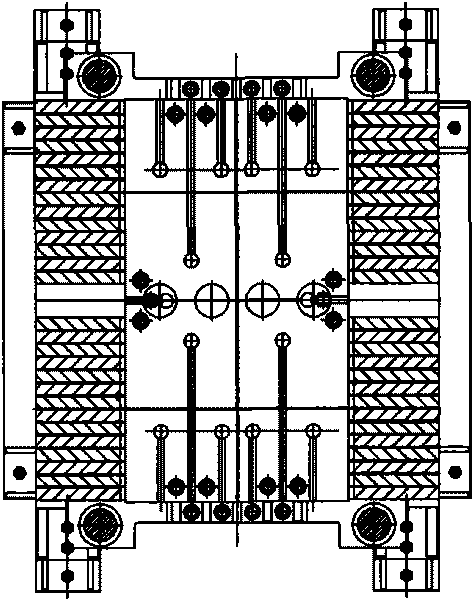

[0016] Accompanying drawing is a kind of specific embodiment of the present invention.

[0017] The 20,000-ton and 30,000-ton large-table double-cylinder double-frame plate-and-frame hydraulic presses of the present invention include a frame and a workbench installed on the frame. The frame is composed of multiple independent plate frames 11 arranged side by side. The two sets of plate-and-frame racks 1 are formed by multiple groups of high-strength screw rods 12 arranged up and down to be pre-tightened laterally. The upper part of the inner side of the frame is fixed with a downward main hydraulic cylinder 3 and a fast hydraulic cylinder 2, and the fast hydraulic cylinders 2 are four located at the four corners of the main hydraulic cylinder, and the piston of each fast hydraulic cylinder 2 is fixed with a downward guide column 6 , the lower end of the main hydraulic cylinder plunger 4 is fixed with a moving beam 5, and the four corners of the moving beam are fixed on four gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com