A kind of electrolytic grinding device for realizing rotating liquid and its working method

A technology of electrolytic grinding and rotary pass, which is applied in the field of electric machining, can solve the problems of low precision in reassembly, time-consuming clamping, and influence on machining accuracy, etc., and achieve the goal of improving the efficiency of reassembly, good liquid supply effect, and expanding engineering applications Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

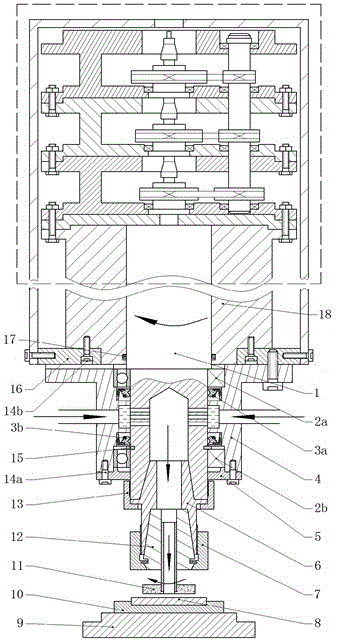

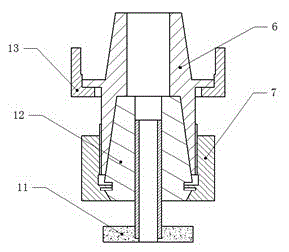

[0022] figure 1 It is a structural schematic diagram of an embodiment of the present invention. The upper dotted line frame is an electrolytic grinding device that realizes high-current and high-speed conduction. It has applied for a patent, and the application number is 201310125655.7. This part uses a coupling to connect multiple identical conductive rings in series, and the conductive ring rotor is connected to the high-speed coupling. , the stator is connected to the low-speed coupling, and the pulley transmission is used to distribute the speed of each coupling, so that the relative speeds of the rotor and the stator of each conductive ring are equal, and the low-speed conductive ring is used for several times the rated value of the rotor and stator. Continuous power supply of the conductive grinding wheel at high speed. The present invention can realize top-to-botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com