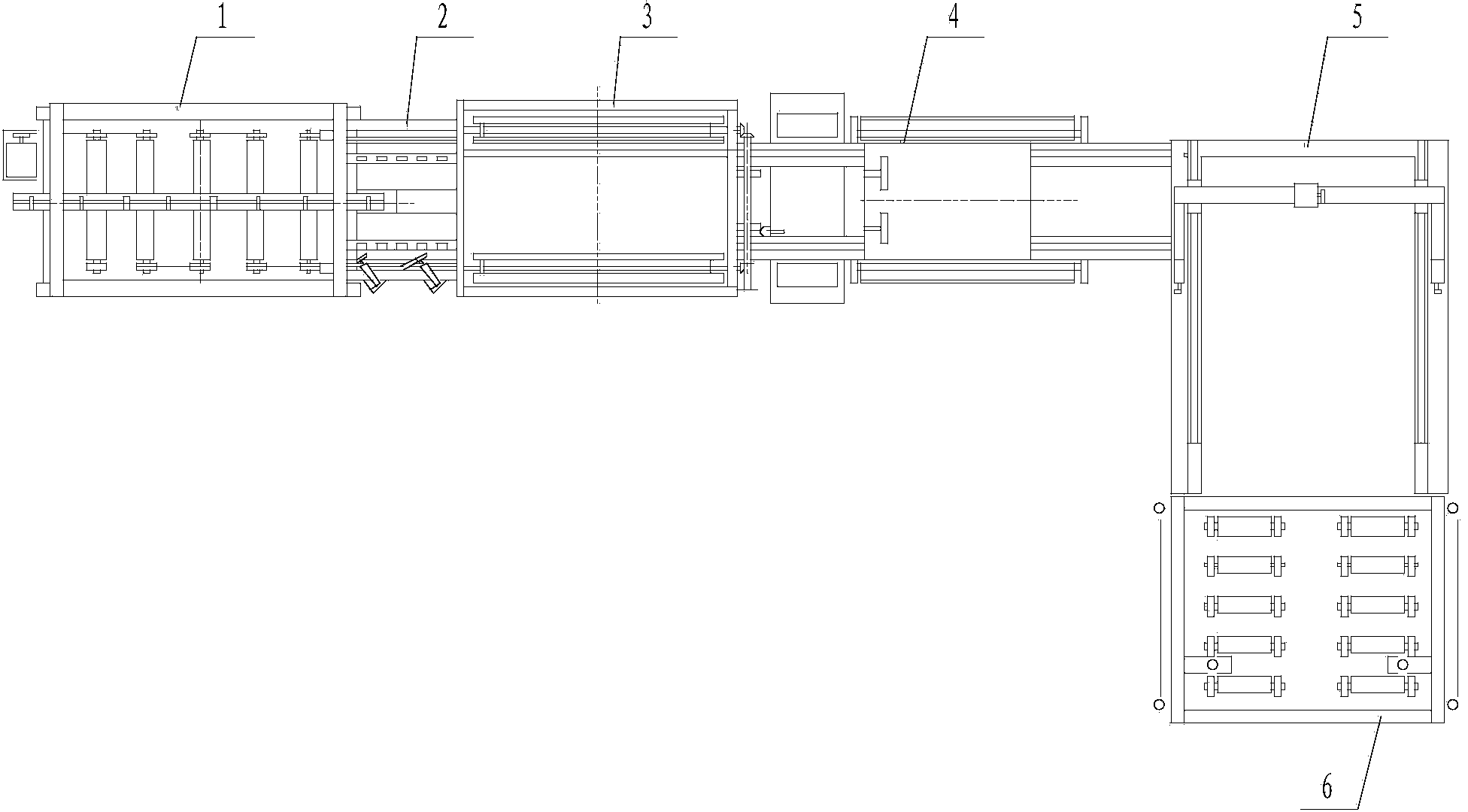

Full-automatic board edge cutting machine

An edge trimming machine, fully automatic technology, used in wood processing appliances, circular saws, sawing components, etc., can solve the problems of chain transmission without any protection, unable to cut wood board, prone to broken chain and chain jam. , to achieve the effect of perfect functions, adding mechanical positioning devices, and improving positioning methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

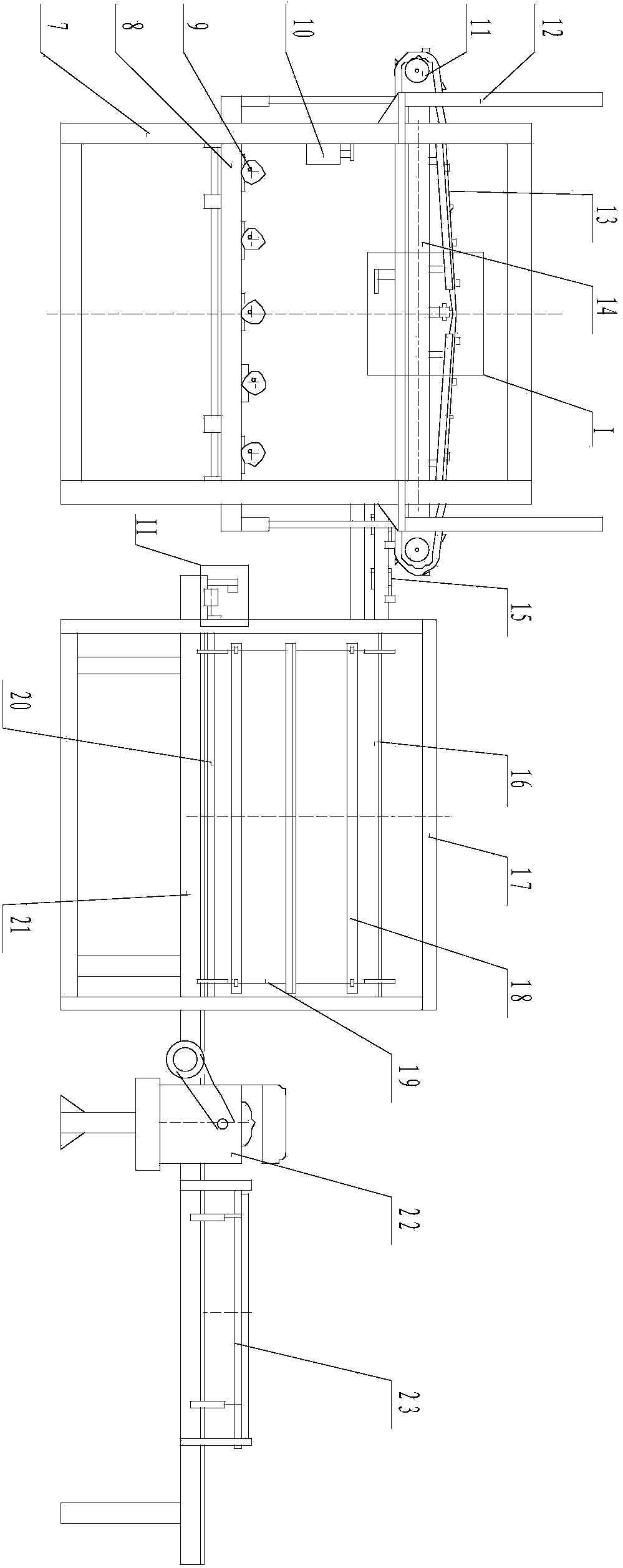

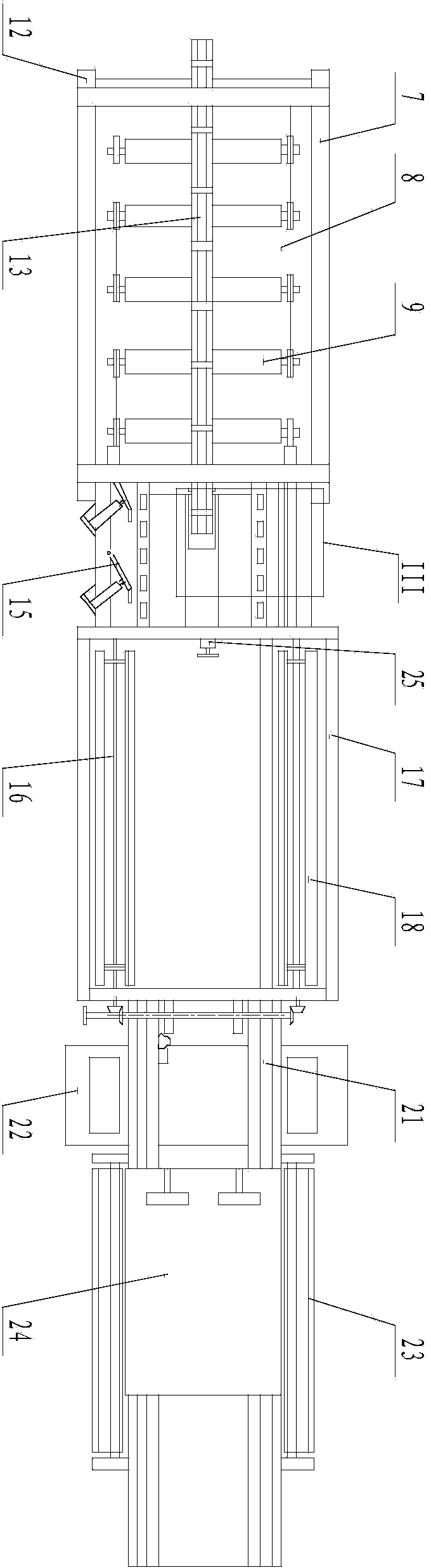

[0030] like Figure 2 to Figure 6 As shown, the board feeding machine 1 includes a feeding elevator and a board feeding device, and the feeding elevator includes a lifting frame 7, and the lifting frame 7 is movably connected to the lifting platform I8 through four lifting cylinders 12, and the lifting platform I8 is provided with rollers for easy feeding I9, one side of the lifting frame I7 is fixed with a roof cylinder 10, and the plate feeding device is fixed above the lifting frame I7. The plate feeding device includes a beam 14 fixed on the lifting frame I7, and two ends of the beam 14 are respectively provided with a transmission wheel 11 , between the two transmission wheels 11 by a transmission chain 113 transmission around the crossbeam 14, the transmission chain I13 is fixedly provided with a slide hook 30 and a chain stay 28, the top of the crossbeam 14 is provided with a chain support frame 26 and a support wheel 27, and the bottom of the crossbeam 14 Be provided w...

Embodiment 2

[0037] The difference between this embodiment and embodiment 1 is that the structure of the positioning device on the positioning platform 2 and the horizontal trimming machine 5 is different, and other structures are exactly the same as embodiment 1. This embodiment is suitable for cutting wood boards. The woodworking board 37 is characterized in that the middle layer is a lot of sticks bonded together and cut into a regular cuboid shape. There is a skew error. If the ordinary positioning method is used, the excess veneer cannot be completely cut off, and the middle layer will be cut irregularly.

[0038] like Figure 9 , Figure 10 As shown, this embodiment has been improved on the basis of Embodiment 1. The positioning device on the positioning platform 2 includes a fixed positioning plate 33 and an elastic positioning device 15, and the fixed positioning plate 33 is fixedly provided with more than two ratchet groups. 36, each ratchet group 36 is provided with more than t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com