Novel damping mechanism of engineering water tank

A technology of shock absorption mechanism and water tank, which is applied in the arrangement of cooling combination of power plant, power plant, transportation and packaging, etc., can solve the problem that the connection between the support sleeve heat dissipation equipment and the connecting frame can not provide buffer protection, and the active space of the heat dissipation equipment increases. large, reduce the life of the radiator, etc., to achieve the effect of long-term effect, simple structure and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

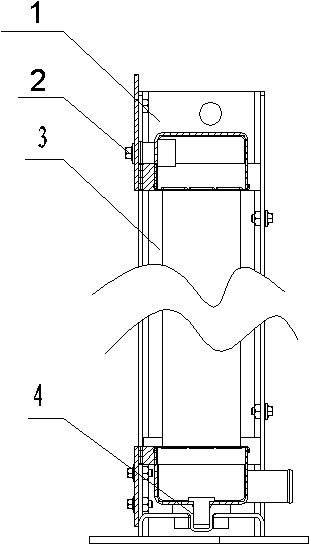

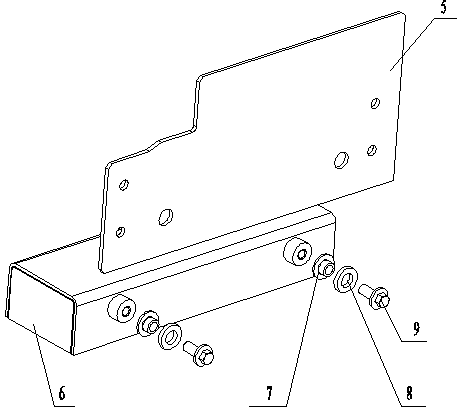

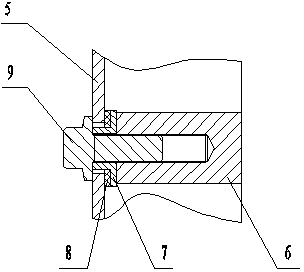

[0014] The new engineering water tank damping mechanism includes an upper connecting part 2 and a lower connecting part 4. The upper connecting part 2 connects and fixes the upper end water chamber 6 of the radiator with the frame 1 through the frame connecting plate 5 of the water tank. The upper connecting part The component 2 includes a connecting bolt 9, a collar rubber pad 8 and a collar iron core 7. The collar rubber pad 8 is set on the collar iron core 7, and the connecting bolt 9 passes through the frame connecting plate 5, The collar rubber pad 8 and the collar iron core 7 are fixed on the water chamber 6 at the upper end of the radiator; the lower connection part 4 is arranged between the support column at the lower end of the radiator 1 and the bottom frame 12, and the lower connection The component 4 is clearance-fitted with the bottom frame 12. The lower connecting component 4 includes a metal attachment sleeve 11 and a shock-absorbing support sleeve 10 nested ther...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com