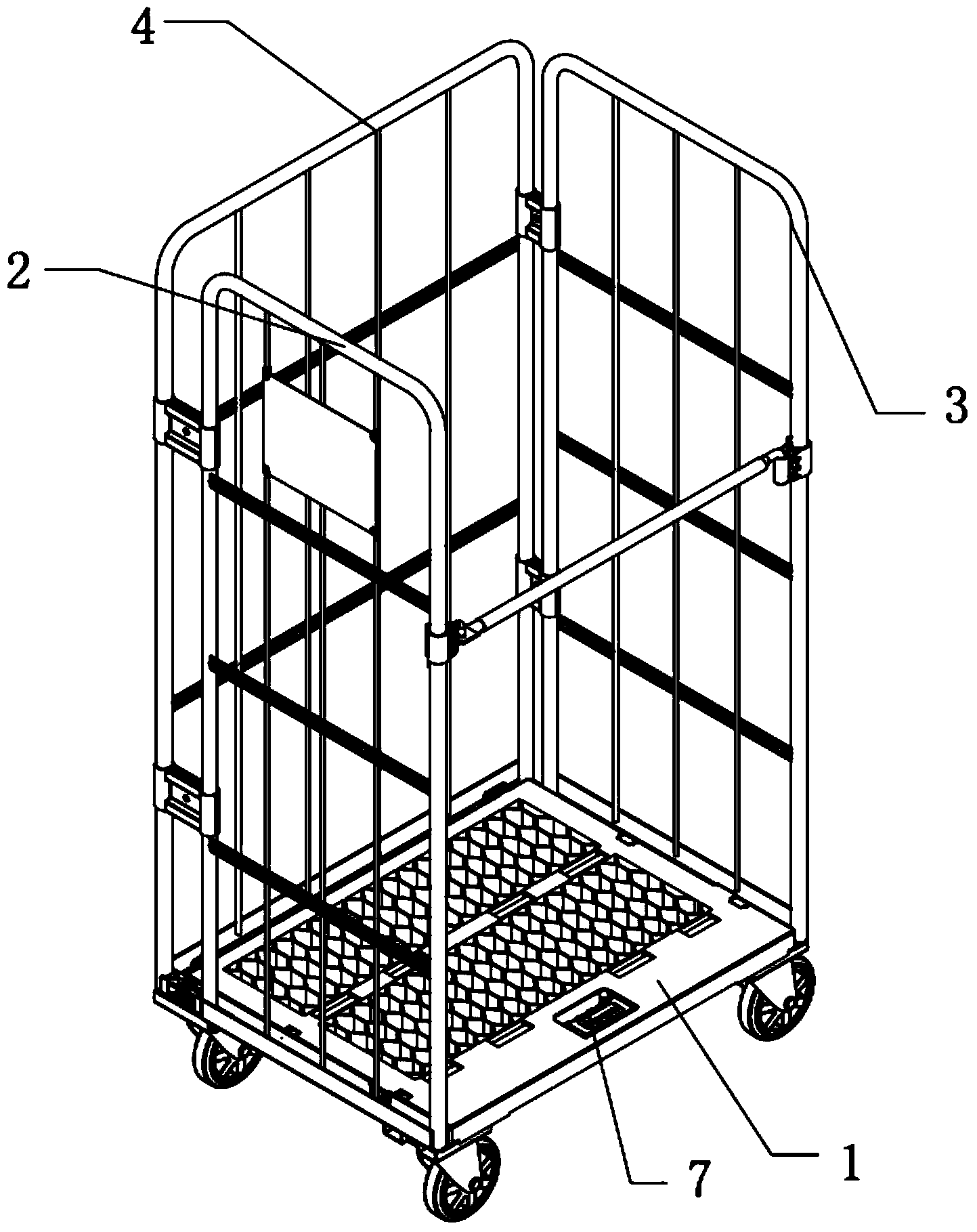

Plastic bottom board logistic trolley

A base plate and logistics technology, applied in trolleys, motor vehicles, multi-axis trolleys, etc., can solve the problems of metal base plates such as heavy weight, troublesome, easy to fall out of the pins, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

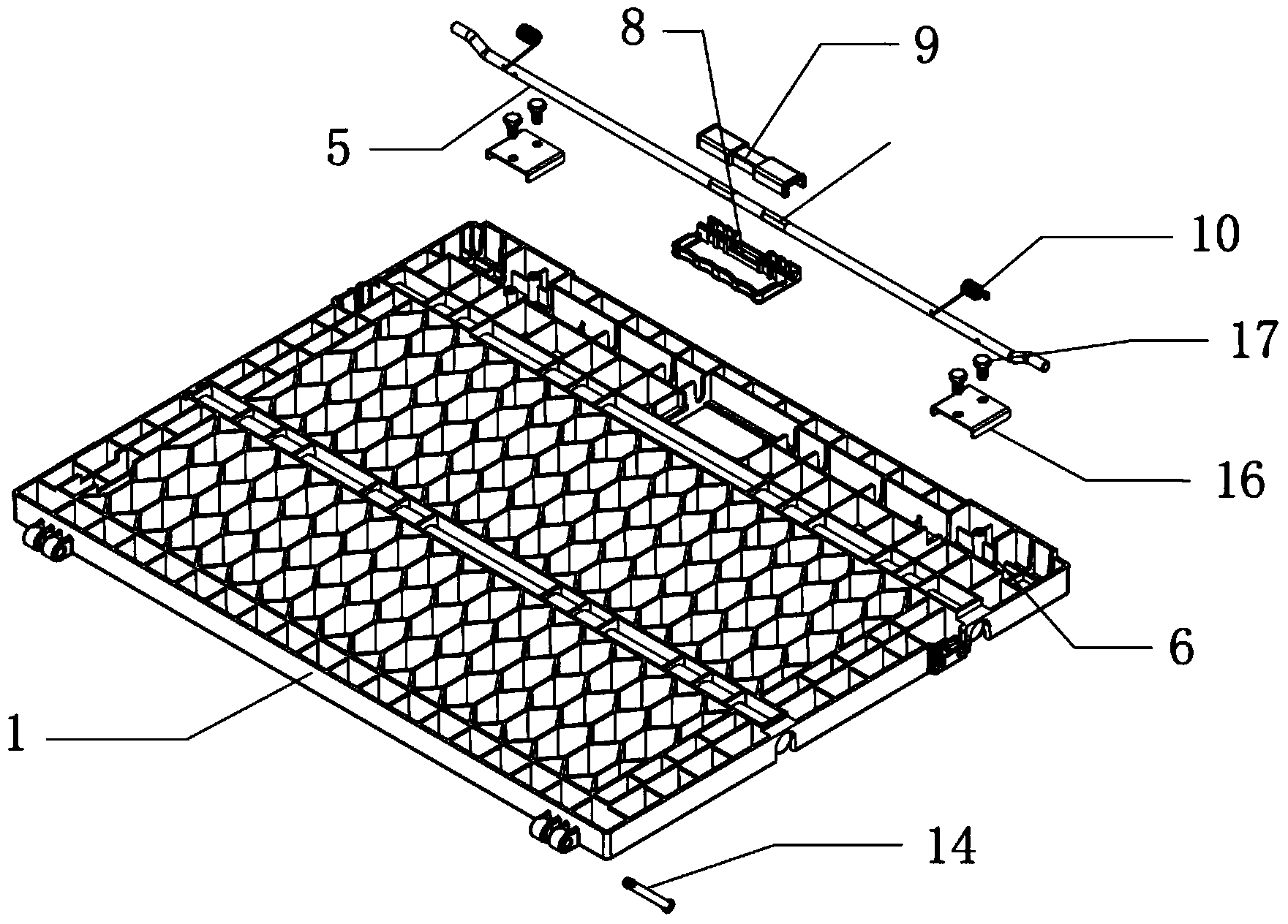

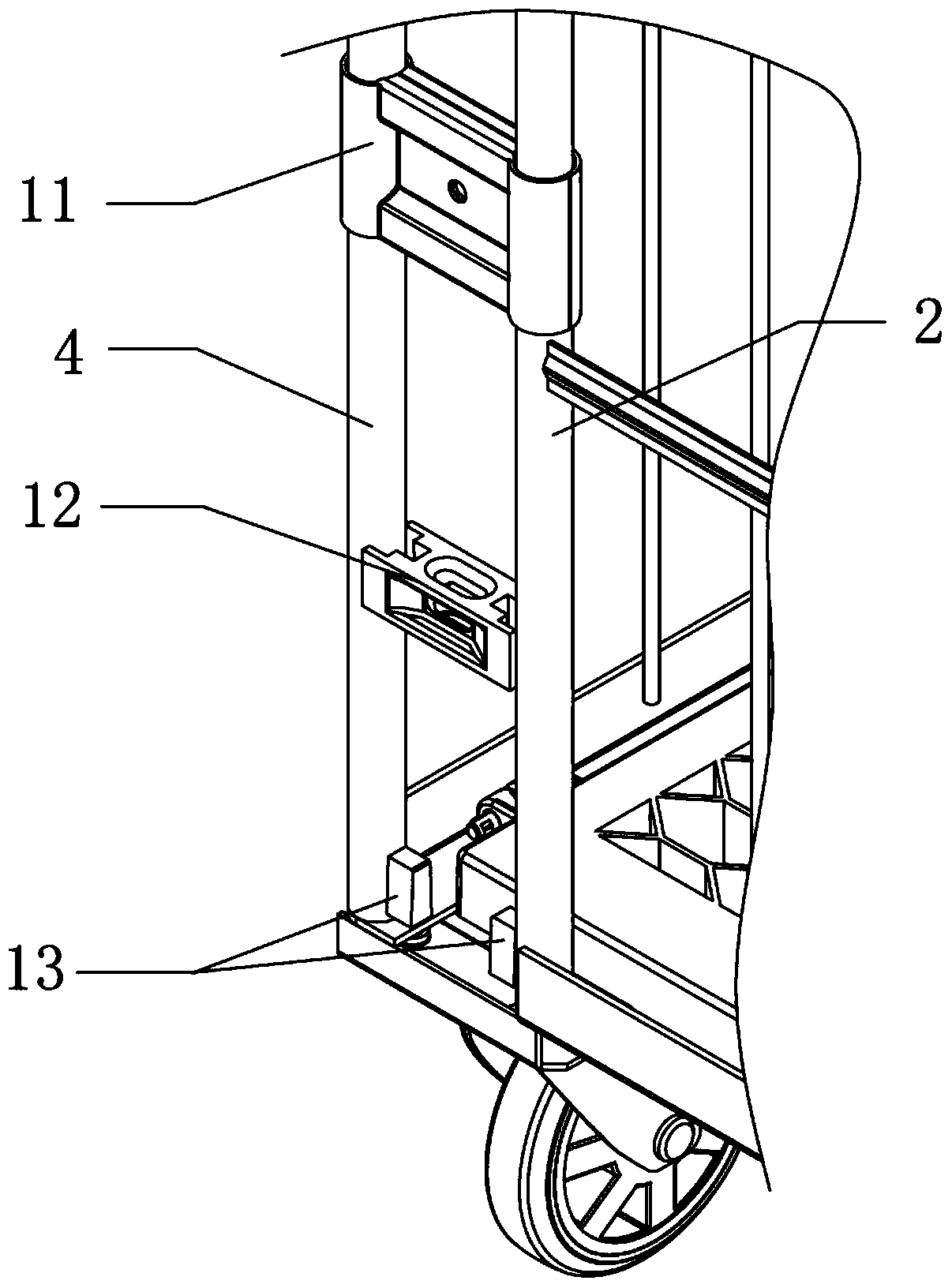

[0026] The plastic floor logistics trolley includes a base plate 1 and a rear column 4, the lower bottom of the rear column 4 is pivotally connected to the base plate 1, the left column 2 is pivotally connected to the left side of the rear column 4, and the right column 3 is connected to the rear column 4. The right side of the right column is pivotally connected, and the left column 2 is locked with the rear column 4 through a wedge-shaped self-locking connection device; the lower bottom of the left column 2 has a left column nose, the lower bottom of the right column 3 has a right column nose, and the bottom plate 1. Lock the left column machine head and the right column machine head through the bottom plate pin bar rotation self-locking device; the bottom plate pin bar rotation self-locking device includes a rotating rod 5, which is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com