Plastic infusion bag arraying mechanism

An infusion bag and plastic technology, which is applied to conveyor objects, conveyor control devices, transportation and packaging, etc., can solve problems such as work efficiency and reliability cannot be guaranteed, full automation of plastic infusion bag packaging is difficult, and labor costs increase. , to solve the problem of manual bag management, reduce production costs and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

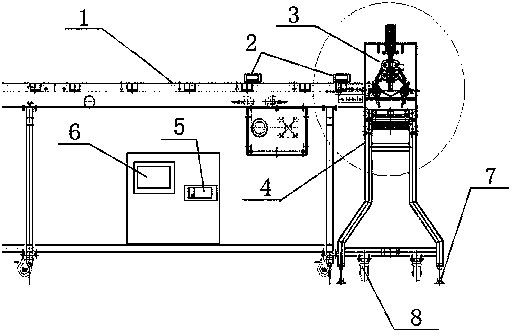

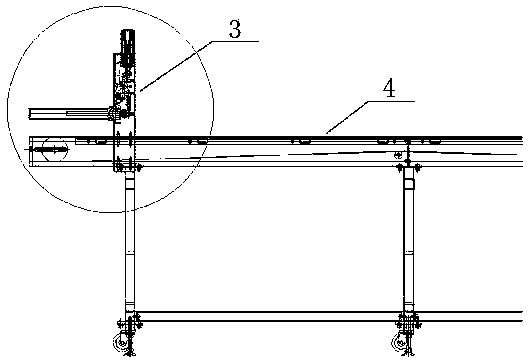

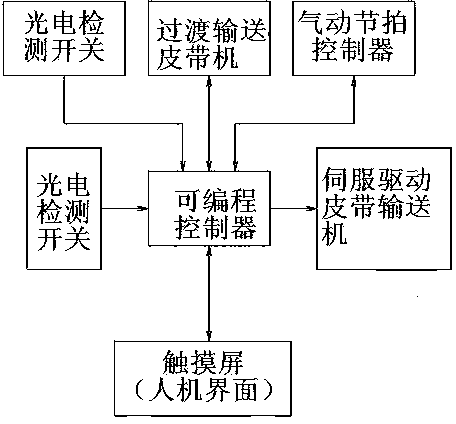

[0012] Such as Figure 1-Figure 4 As shown, the plastic infusion bag alignment mechanism includes a servo-controlled belt conveyor 1, a photoelectric detection switch 2, a pneumatic beat controller 3, a transition conveyor belt conveyor 4, a programmable controller 5, and a touch screen 6, and the servo-controlled belt conveyor 1. Pneumatic tempo controller is placed at 90° to transition conveyor belt conveyor 4. 3 is set between servo-controlled belt conveyor 1 and transition conveyor belt conveyor 4. Photoelectric detection switch 2 is set on servo-controlled belt conveyor 1. The programming controller 5 and the touch screen 6 are set at the bottom of the servo-controlled belt conveyor 1, and the bottom of the transitional conveyor belt conveyor 4 is equipped with feet 7 and casters 8, and the infusion bags coming out of the light inspection machine are transported to the servo-controlled belt conveyor 1 Above, the belt conveyor 1 has a relatively high speed, so that the dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com