Rope wheel with self-locking device

A technology of self-locking device and rope wheel, which is applied in hoisting device and clockwork mechanism, etc., can solve the problems of high labor intensity, broken rope, falling of heavy objects, etc., and achieve the effect of reducing safety risks and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

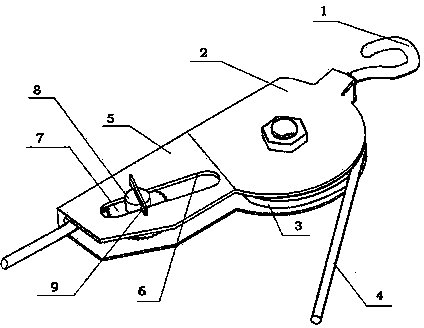

[0017] figure 1 The sheave with self-locking device shown in the embodiment includes a runner 3, a steel wire rope 4, a support frame 2, and a self-locking device is also included on the support frame 2, and the steel wire rope 4 passes through the self-locking device.

[0018] Further explain the present embodiment, since the sheave is fixed, a self-locking device is installed on the sheave, the self-locking device and the support frame 2 of the sheave are directly fixed, and the wire rope 4 of the sheave is passed through the self-locking device out. The beneficial effect produced in this way is that after the rope wheel and the self-locking device are fixed together, it is convenient to carry the whole tool body, and the rope wheel also passes through the self-locking device during the process of threading the steel wire rope 4, so there is no need to repeatedly thread the wire during installation . The purpose of installing a self-locking device on the sheave is to prev...

Embodiment 2

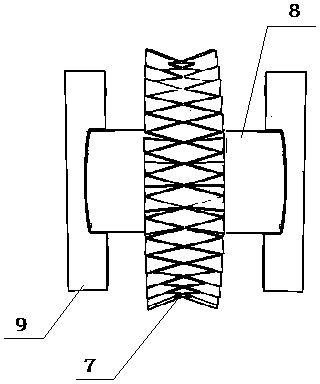

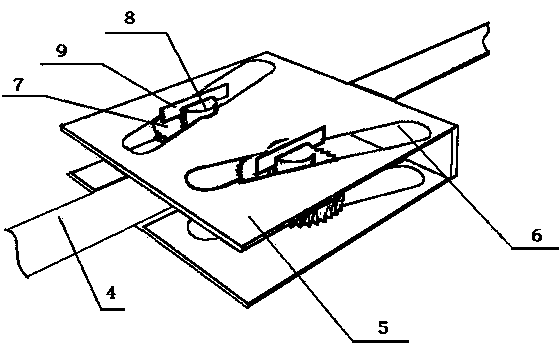

[0025] Such as image 3 The difference between the self-locking device shown in this embodiment and the first embodiment is that the self-locking device includes two rollers 7 and two pairs of slotted holes 6 .

[0026] Further explain the present embodiment: the structure of the self-locking device in the present embodiment is different from the self-locking device of embodiment 1. Two rollers 7 are used to rub and squeeze the steel rope 4. When the steel rope 4 descends, the two rollers 7 descend simultaneously. Squeeze and lock the wire rope 4 from two directions at the same time, so that the wire rope 4 can be locked after falling a small distance. The beneficial effect of this embodiment is that the wire rope can be locked more accurately and quickly, improving work efficiency and ensuring the safety of operators.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com