Computerized flat knitting machine inlaid yarn nozzle transmission device

A transmission device, computerized flat knitting technology, applied in textile and papermaking, weft knitting, knitting and other directions, can solve problems such as affecting normal work, loosening of intarsia yarn feeders, affecting the stability of movement of intarsia yarn feeders, etc. The effect of expanding diversity and increasing the number of distributions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

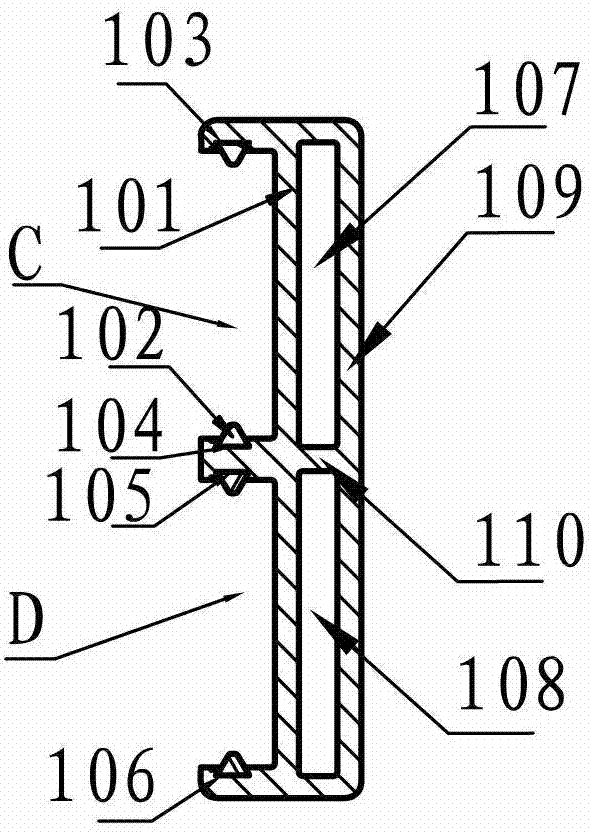

[0038] The preferred embodiments of the present invention will be further described in detail with reference to the accompanying drawings.

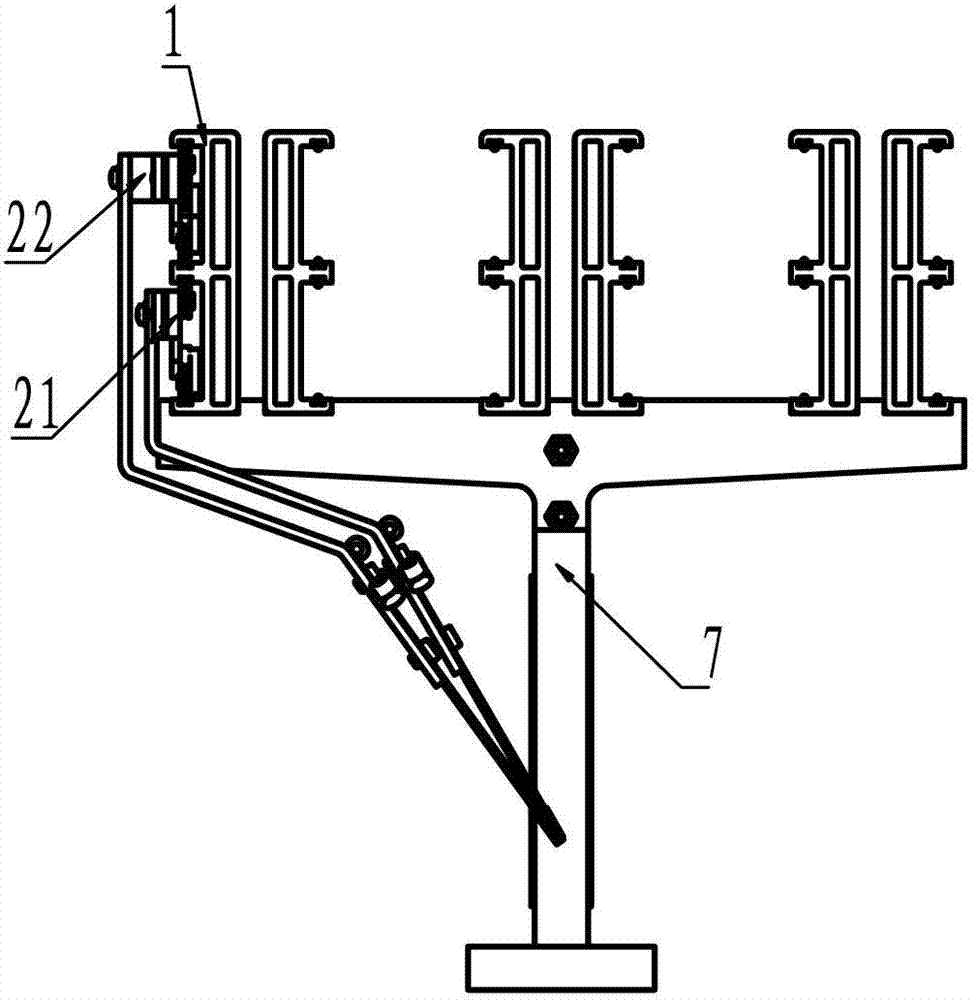

[0039] The main components included in the present invention are a shuttle guide rail assembly 1, and two groups of yarn feeder moving assemblies 21 and 22 installed on the shuttle guide rail assembly 1.

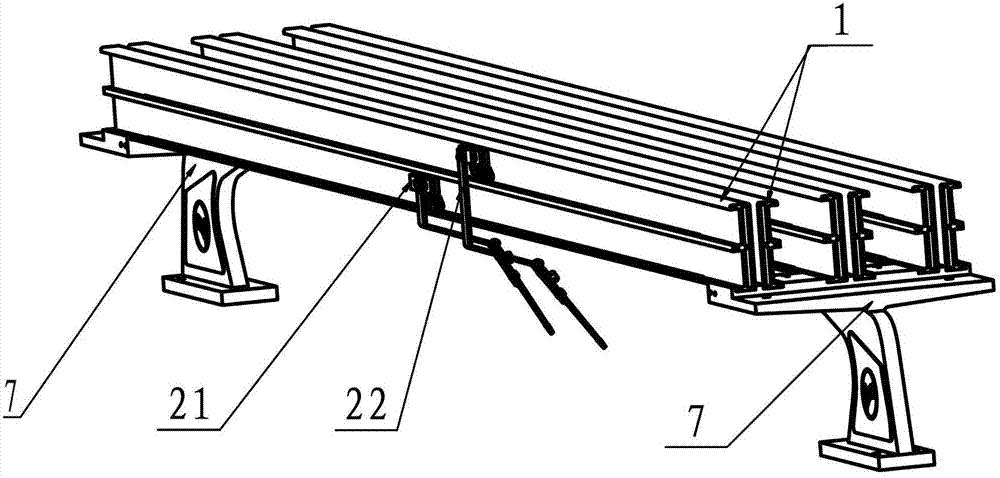

[0040] When the present invention is actually assembled, it is fixedly mounted on the left and right shuttle rail seats 7 of the machine, such as figure 1 As shown, the yarn feeder moving assemblies 21 and 22 are respectively installed on the same side of each group of shuttle guide rail assemblies 1, and are distributed up and down; every two shuttle guide rail assemblies 1 are arranged back-to-back, that is, two shuttle guide rail assemblies 1. Symmetrically arranged, the sides of the yarn feeder moving assemblies 21 and 22 are installed facing outward to form a pair, such as figure 1 , 2 shown. Multiple pairs of shuttle guide rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com