Submersible axial-flow pump with inbuilt impeller

A built-in, axial-flow pump technology, applied in the direction of non-variable pumps, pumps, pump devices, etc., can solve the problems of difficult to ensure motor sealing, friction accidents of impeller shells, poor anti-vibration performance, etc., to reduce strength and Rigidity requirements, lower installation accuracy requirements, and improved safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

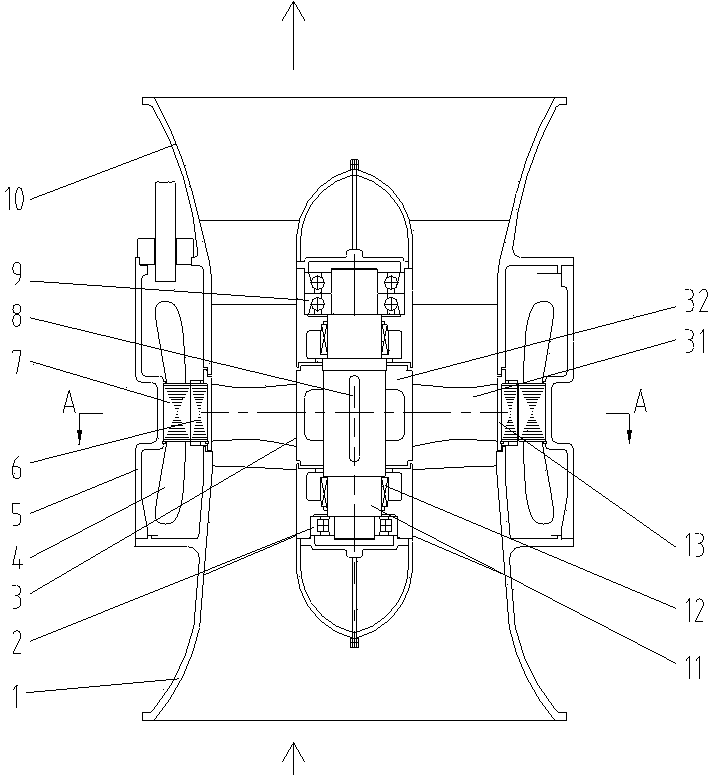

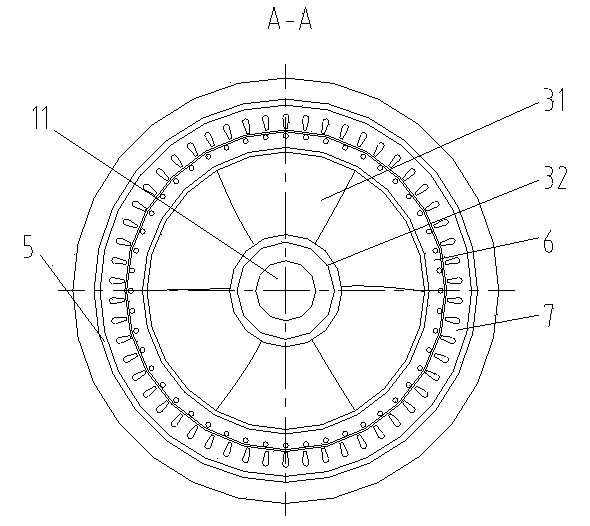

[0019] see figure 1 and figure 2 , a submersible axial flow pump with a built-in impeller includes a coaxially penetrated water suction chamber 1, an impeller hub 32, and a water outlet chamber 10. A rotating shaft 11 is installed in the axial middle of the three, and one end of the rotating shaft 11 passes through the water suction end bearing and the water suction bearing chamber. The cooperation of the water outlet is located in the water absorption chamber 1; the other end is located in the water outlet chamber 10 through the cooperation of the water outlet bearing and the water outlet bearing chamber; the impeller hub 32 is fixedly installed on the rotating shaft 11 through the key 8; it also includes the motor rotor 6, the motor stator 7 and the circle The ring-shaped stator housing 5, the motor stator 7 is fixedly installed in the stator housing 5, the axial ends of the stator housing 5 are respectively connected to the middle of the outer circumference of the water su...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap