Toothless synchronizing ring and synchronizer

A technology of synchronizing ring and tooth shape, applied in clutches, mechanical drive clutches, mechanical equipment, etc., can solve the problems of high cost and complicated manufacturing process, and achieve the effect of reducing manufacturing cost, simple manufacturing and realizing guiding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

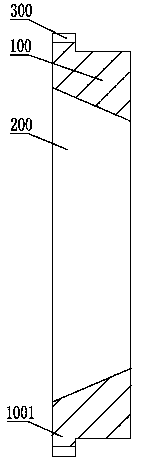

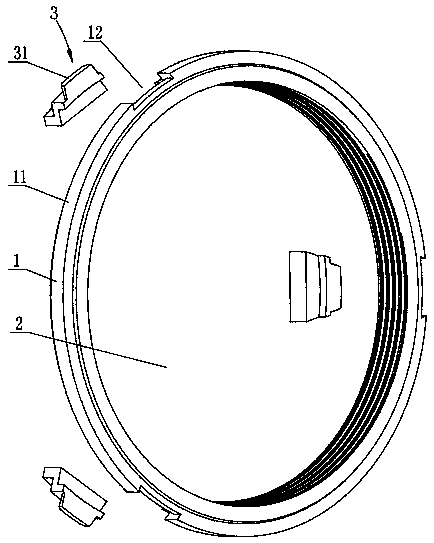

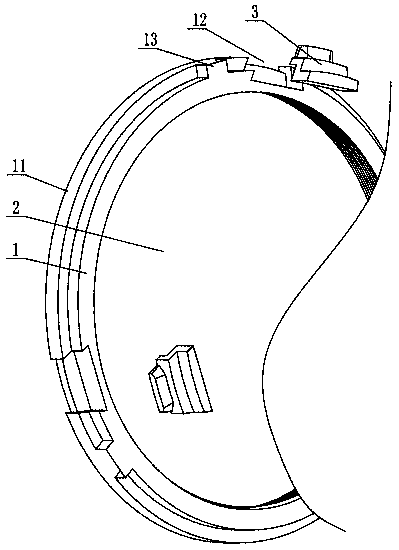

[0019] See figure 2 , the present invention comprises an annular base body 1, the base body 1 is provided with an inner tapered hole 2, and one end of the base body 1 located at the large diameter end of the inner tapered hole 2 is provided with a flange end 11, and the outer peripheral surface of the base body 1 is axially At least three grooves 12 are evenly distributed, the grooves 12 are stepped, and the locking protrusion 3 has a wide tooth-shaped protrusion 31. After the locking protrusion 3 is embedded in the groove 12, the wide tooth-shaped protrusion The portion 31 is located on the outer circumferential surface of the flange end 11 and protrudes radially outward.

[0020] Specifically, the two side arms of the recess on the flange end 11 of the stepped groove 12 have side recesses, the side recesses open toward the groove 12, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com