Laser device

A laser and laser technology, applied in the field of lasers, can solve the problems of low power of red light, large deviation of guiding position, easy to be affected by temperature changes, etc., and achieve the effect of reducing cost, ensuring stability, ensuring brightness and guiding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

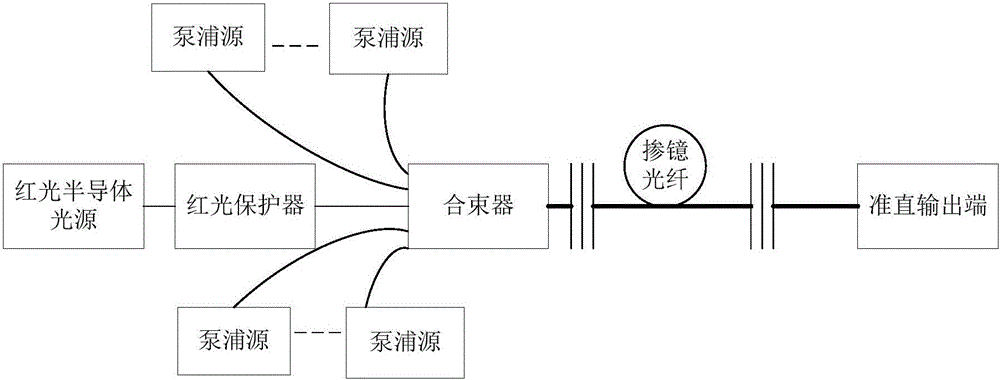

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the drawings and embodiments.

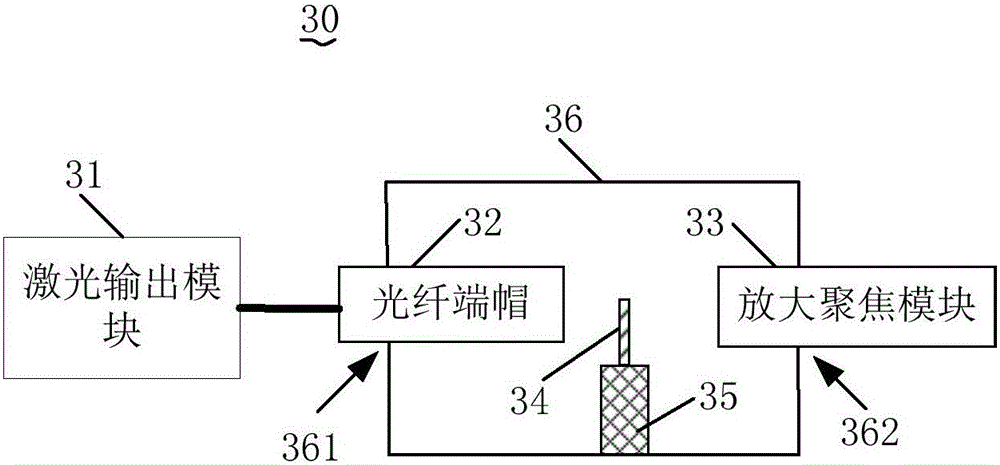

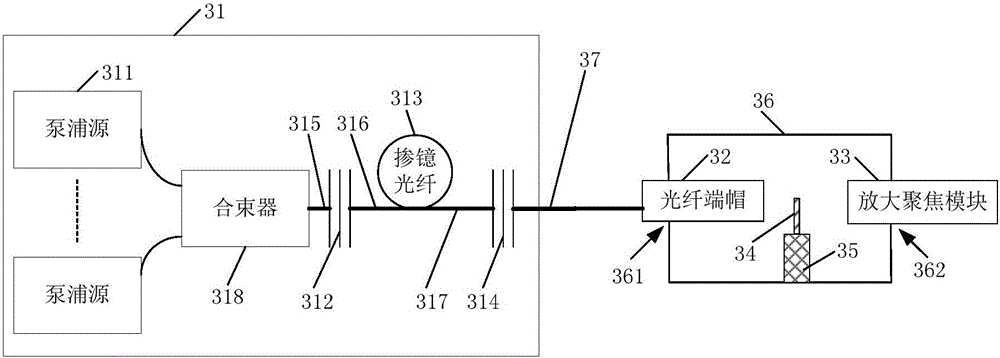

[0026] See figure 2 , The laser 30 includes a laser output module 31, an optical fiber end cap 32, an amplifying and focusing module 33, and a frequency doubling wafer 34.

[0027] The laser output module 31 is used to output laser. The fiber end cap 32 is connected to the laser output module 31 and is used to receive and output the laser light output by the laser output module 31. The magnifying and focusing module 33 is disposed opposite to the fiber end cap 32 so that the laser light output from the fiber end cap 32 is incident on the magnifying and focusing module 33. The frequency doubling wafer 34 is arranged between the fiber end cap 32 and the magnifying and focusing module 33, and is located in the transmission direction of the laser light output from the fiber end cap 32, so that at least part of the laser light output from the fiber end cap 32 is from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com