Laser

A laser and laser technology, applied in the field of lasers, can solve the problems of being easily affected by temperature changes, insufficient red light brightness, and low red light power, etc., and achieve the effects of good guidance, high brightness, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

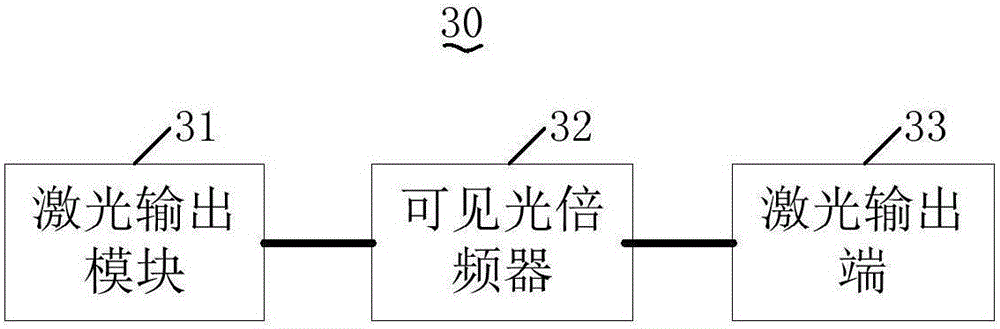

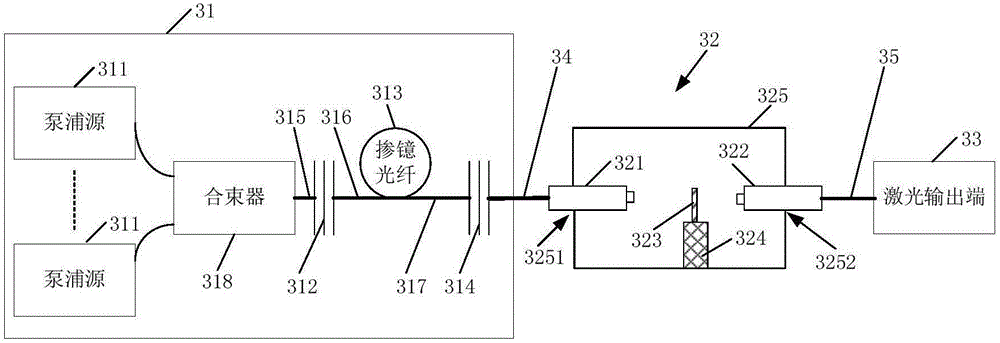

[0026] see figure 2 , the laser 30 includes a laser output module 31 , a visible light frequency doubler 32 and a laser output terminal 33 .

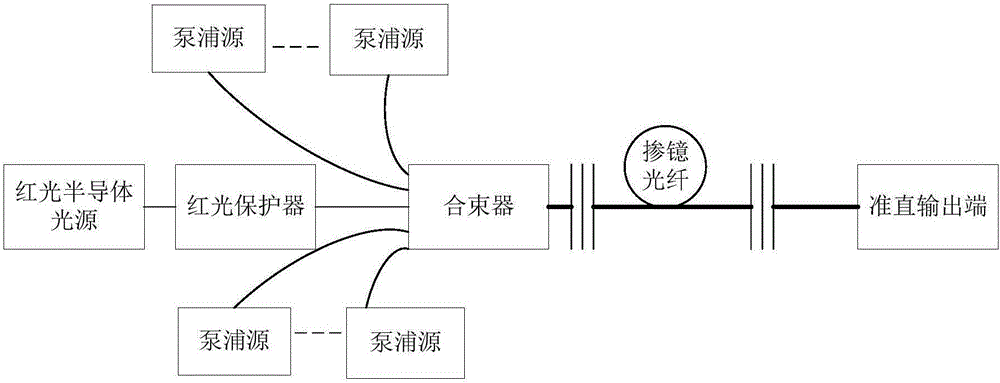

[0027] The laser output module 31 is used for outputting laser light. The visible light frequency doubler 32 is connected with the laser output module 31 for receiving laser light and converting part of the laser light into visible light. The laser output terminal 33 is connected with the visible light frequency multiplier 32 for receiving and outputting unconverted laser light and visible light, wherein the visible light is used as the guide light. Since both laser light and visible light are output through the laser output terminal 33 , the focal point of the visible light on the target is the focal point of the laser on the target, which realizes the guiding effect on the laser. By using the visible ligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com