A pot-stove integrated shrimp cooking machine

An integrated, pot-stove technology, which is applied in household stoves/stoves, shrimp/lobster processing, solid heating fuel, etc., can solve the problems of low continuity and automation, high cost of steam boilers, and poor cooking effects, etc., to achieve Save the initial investment, solve the difficulty of approval, and improve the effect of cooking shrimp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

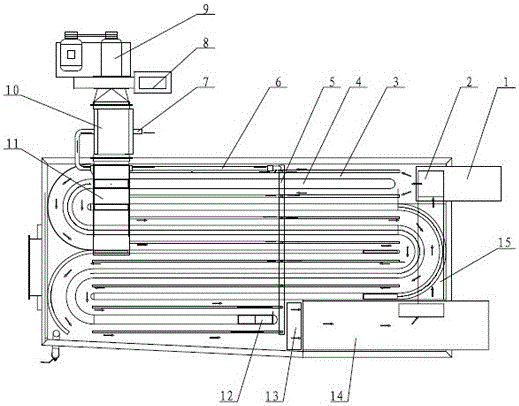

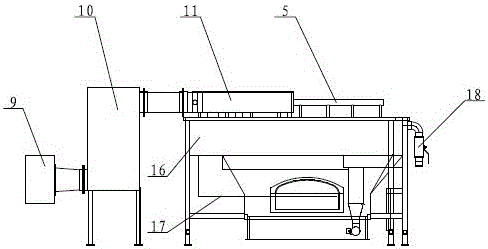

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

[0015] As shown in the figure, a cooker with integrated pot and stove includes a stove 17 and a cooking pot 16 . A combustion chamber is provided in the stove 17 for heating. The cooking pot 16 is a rectangular groove structure, and one side of the cooking pot 16 is provided with a drain pipe 18 . The cooking pot 16 is provided with a continuously bent shrimp cooking waterway 3, and the shrimp cooking waterway 3 is provided with a flue 4, and the flue 4 runs through the whole shrimp cooking waterway 3, and the flue 4 separates the shrimp cooking waterway 3 at least into Two-channel structure. The flue 4 communicates with the stove 17 through the set smoke outlet 12 to enter the hot smoke, and the flue 4 communicates with the secondary heat exchanger 11 arranged on the cooking pot 16, and the secondary heat exchanger 11 is connected to the primary heat exchanger 10. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com