Workshop constant temperature and humidity system and control method thereof

A constant temperature and humidity, workshop technology, used in heating and ventilation control systems, heating and ventilation safety systems, heating methods, etc., can solve the problem of not being able to adjust the temperature and humidity of local spaces, and achieve the effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

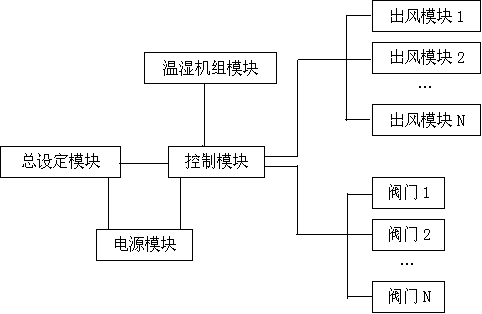

[0020] Such as figure 1 As shown, the present invention discloses a workshop constant temperature and humidity system, which includes a general setting module, a temperature and humidity unit module, a control module, a power supply module, at least one channel and at least one air outlet module, wherein each air outlet module passes through One channel is connected to the temperature and humidity unit module, and each channel is provided with a valve, each valve is electrically connected to the control module, the power module is electrically connected to the temperature and humidity unit module and the control module, and the control module They are respectively electrically connected to the general setting module, the temperature and humidity unit module and the air outlet module.

[0021] The unit module includes humidification unit, dehumidif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com