An optical fiber distributed multi-point online gas monitoring system and its host

An optical fiber distributed, gas monitoring technology, applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of short monitoring distance and complicated control of the monitoring system, and achieve the effects of stable and reliable performance, convenient use, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific embodiment the utility model is further introduced.

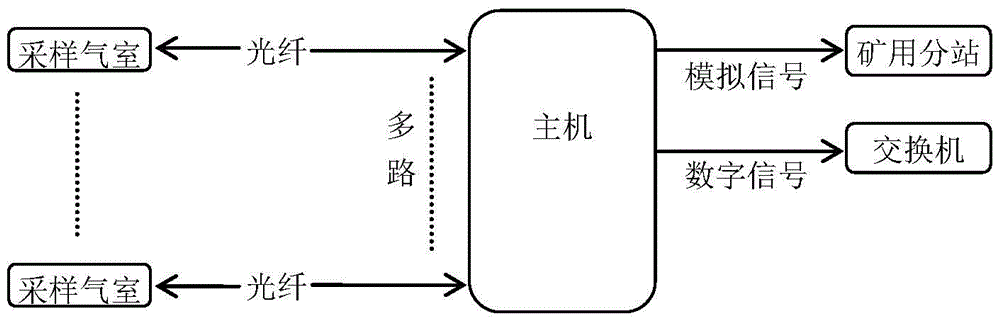

[0023] Such as figure 1 Shown is the topological diagram of the optical fiber distributed multi-point online gas monitoring system of the utility model. The system includes a host and monitoring probes distributed at each monitoring point. The host is set at a distance from each monitoring point and is convenient for installation. , the position of maintenance, and the corresponding gas sampling device (the gas sampling device of this embodiment is a sampling gas chamber) is arranged in the monitoring probe, and is distributed and installed in the place to be monitored, and the gas to be measured can freely enter and exit the sampling gas chamber; The sampling gas chamber is connected with the host by optical fiber.

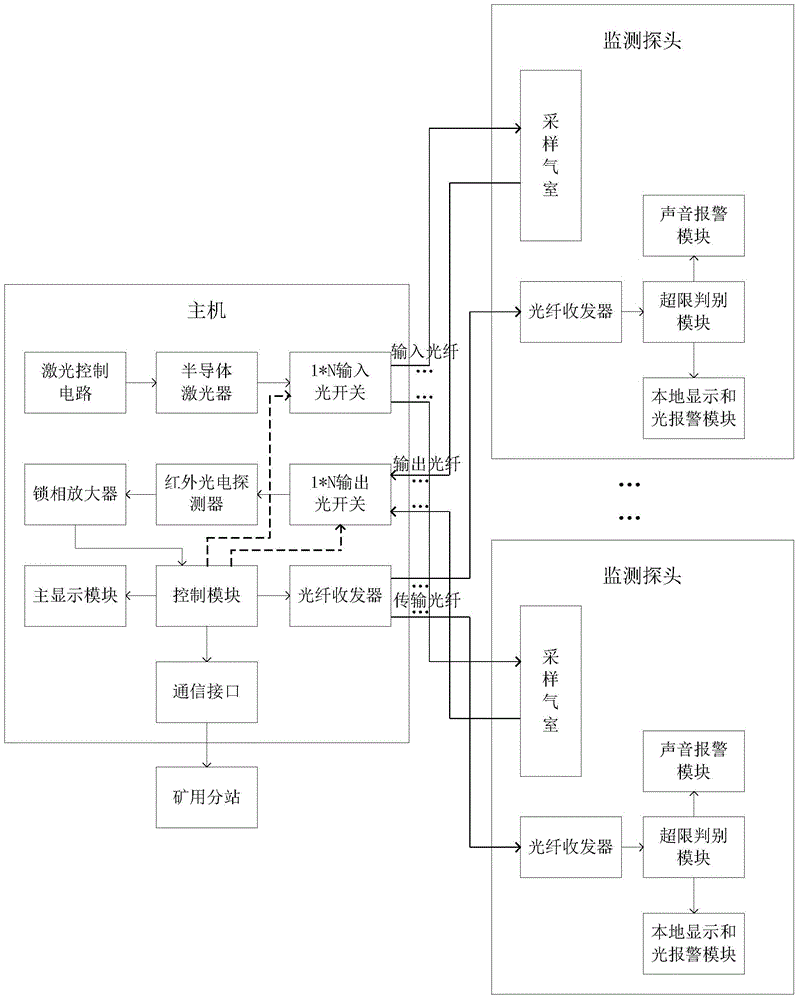

[0024] Such as figure 2 Shown is a schematic structural diagram of an embodiment of an optical fiber distributed multi-point online gas mon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com