An optical fiber distributed multi-point online gas monitoring system and its host

一种光纤分布式、气体监测的技术,应用在颜色/光谱特性测量等方向,能够解决监测系统监测距离短、控制复杂等问题,达到性能稳定可靠、使用方便、便于现场安装的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

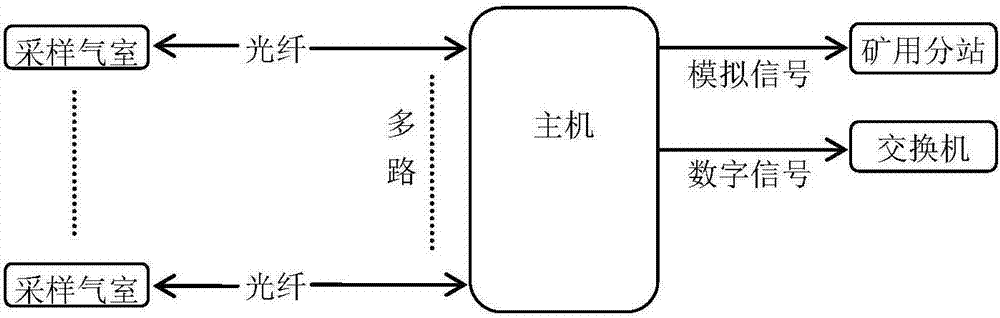

[0022] Such as figure 1 Shown is the topological diagram of the optical fiber distributed multi-point online gas monitoring system of the present invention, the system includes a host and monitoring probes for distribution at each monitoring point, the host is set at a distance from each monitoring point, and is convenient for installation, The location for maintenance, and the corresponding gas sampling device (the gas sampling device in this embodiment is a sampling gas chamber) is arranged in the monitoring probe, and is distributed and installed in the place to be monitored, and the gas to be measured can freely enter and exit the sampling gas chamber; each sampling The air chamber is connected with the host by optical fiber.

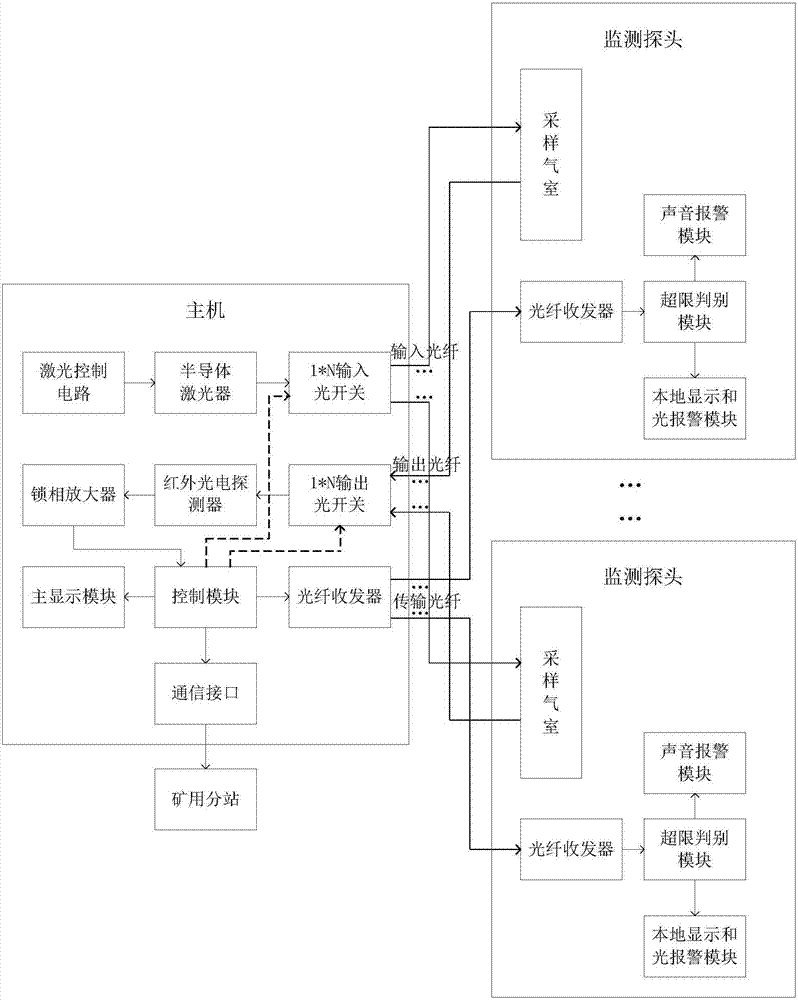

[0023] Such as figure 2 Shown is a schematic structural diagram of an embodiment of an optical fiber distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com