Portable flaw detection device for steel wire rope

A detection device and wire rope technology, applied in the direction of material magnetic variables, etc., can solve the problems of inconvenience to carry, complex structure of the detection device, portable wire rope damage detection device, etc. boosted effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

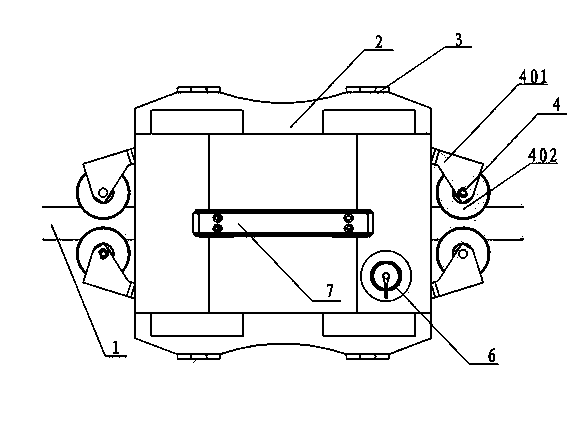

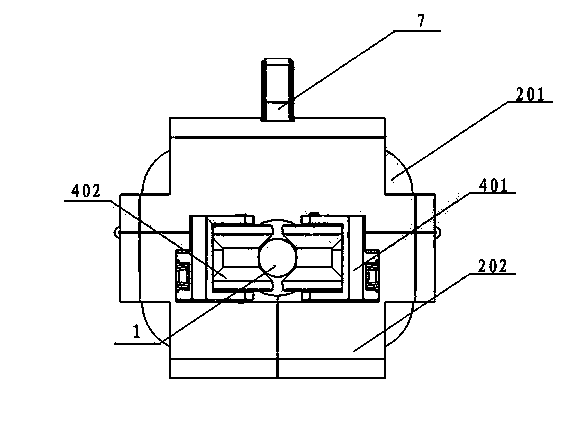

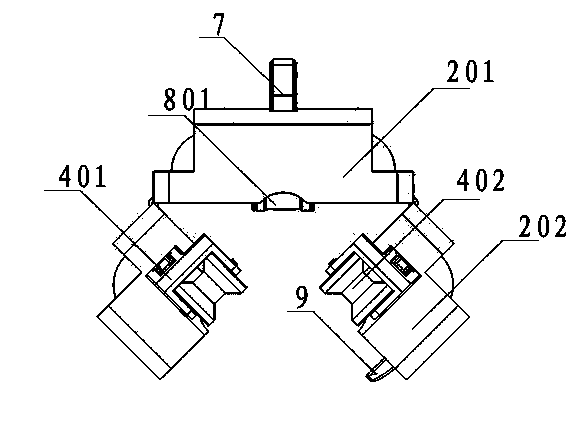

[0035] figure 1 As shown, the specific implementation is as follows:

[0036] A portable wire rope damage detection device, comprising a housing 2 composed of a fixed housing 201 and two movable housings 202, an excitation shielding unit 11, a detection induction unit 10 for inductively processing the magnetic signal of the excitation shielding unit 11, and a stroke calculation unit 8 1. The guide holding unit 4 used to control the direction of travel of the detection device and the hand-held instrument 12 with a built-in power supply. The two movable shells 202 are arranged on the same side of the fixed shell 201, and one side of the two movable shells 202 is oppositely arranged, and the other The sides are respectively connected with the two sides of the fixed shell 201 through the hinge 3, and the two movable shells 202 are provided with a locking mechanism 9 that restricts their rotation around the hinge 3, and the two movable shells 202 rotate until they fit the fixed she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com