High-voltage switch barrel and high-voltage switch using same

A high-voltage switch and barrel technology, applied in the field of high-voltage switches and high-voltage switch barrels, can solve the problems of time-consuming and labor-intensive leak detection, and inability to guarantee sealing performance, and achieve the effects of reducing processing difficulty, reducing the impact of strength and reducing the impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

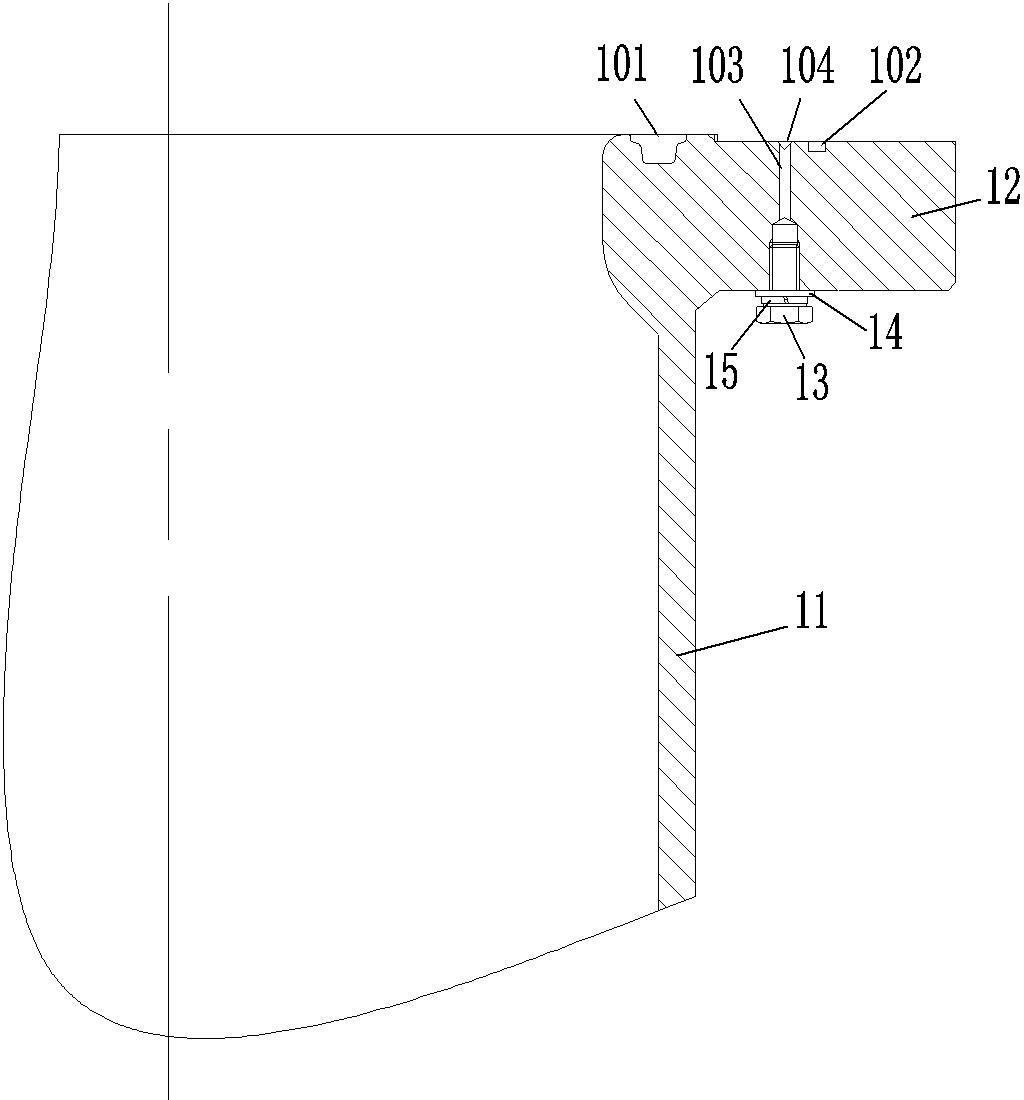

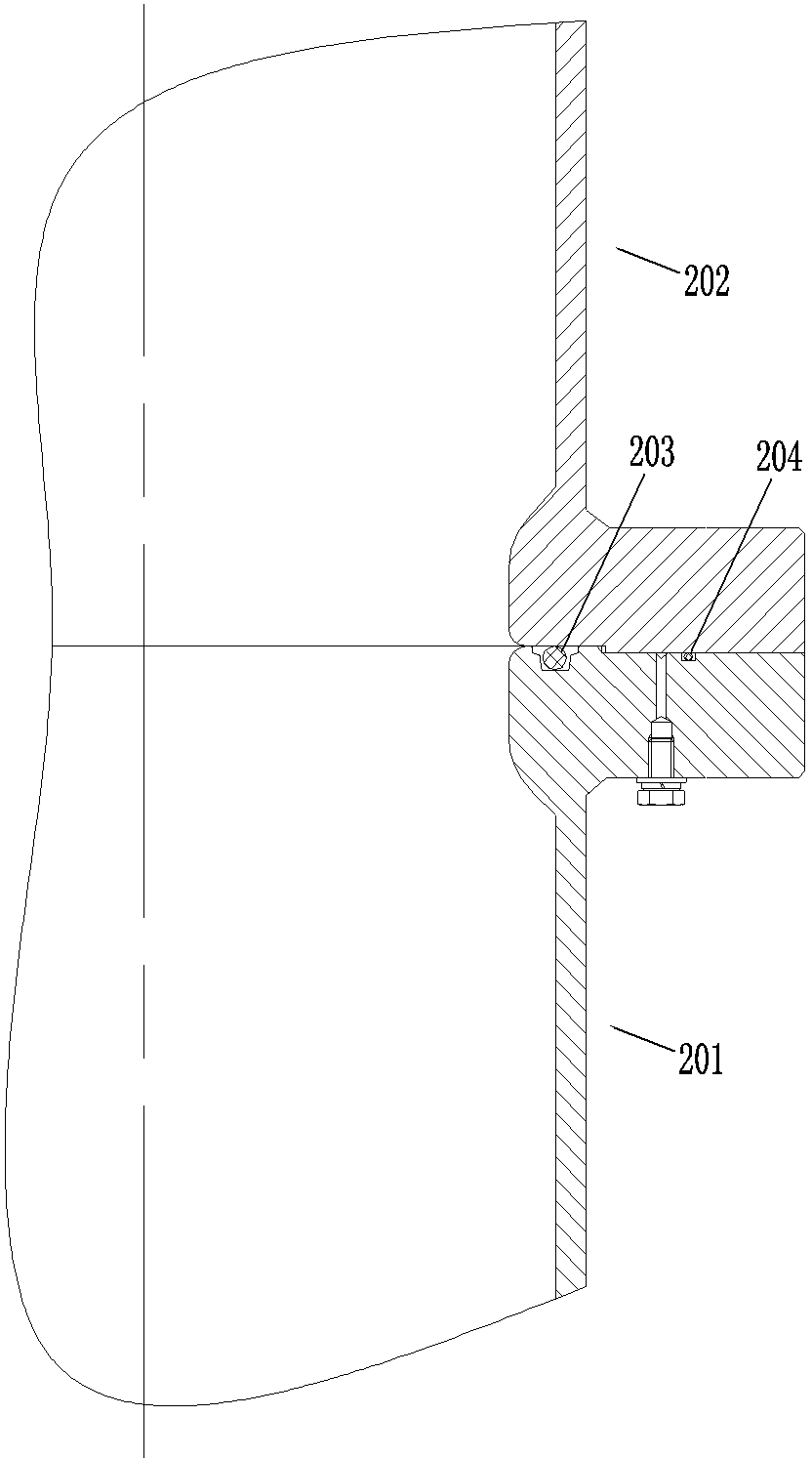

[0021] An embodiment of the high-voltage switch cylinder of the present invention, hereinafter referred to as the cylinder, such as figure 1 As shown, one end of the cylinder body 11 has a sealing structure for sealingly mating with the adapter terminal fitting. The sealing structure includes a flange plate 12 arranged at the corresponding end of the cylinder body 11. The flange plate 12 is used for connecting with the terminal fitting. (It can be another high-voltage switch cylinder, or a cover plate) The side of the butt joint is the connection side, and the other side is the back side. There is a sealing ring groove 101 on the connecting side. When in use, the sealing ring groove can be A sealing ring is assembled in 101 to ensure the sealing of the fit between the cylinder body and the corresponding terminal fitting, thereby preventing gas leakage in the cylinder body. In addition, the flange 12 has a sealing portion at the outer edge of the connection side, The sealing pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com