Wrapper oil coating process and automatic oil coating device for continuous wrapper production

An oiling device and dough technology used in dough processing, baking, food science, etc. to enrich product varieties and ensure standardization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

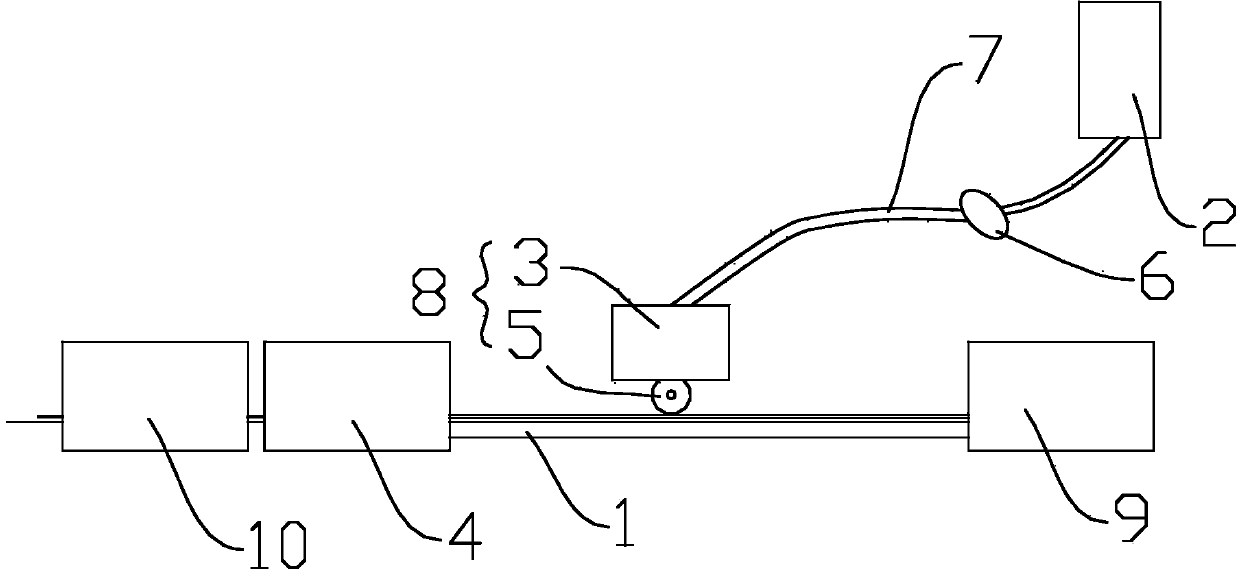

[0064] Dough oiling process, the steps are as follows:

[0065] ①. Pre-treat the shortening. Stir and shear the solid shortening through the pulping equipment to obtain viscous shortening. Please refer to Table 1 for each control parameter.

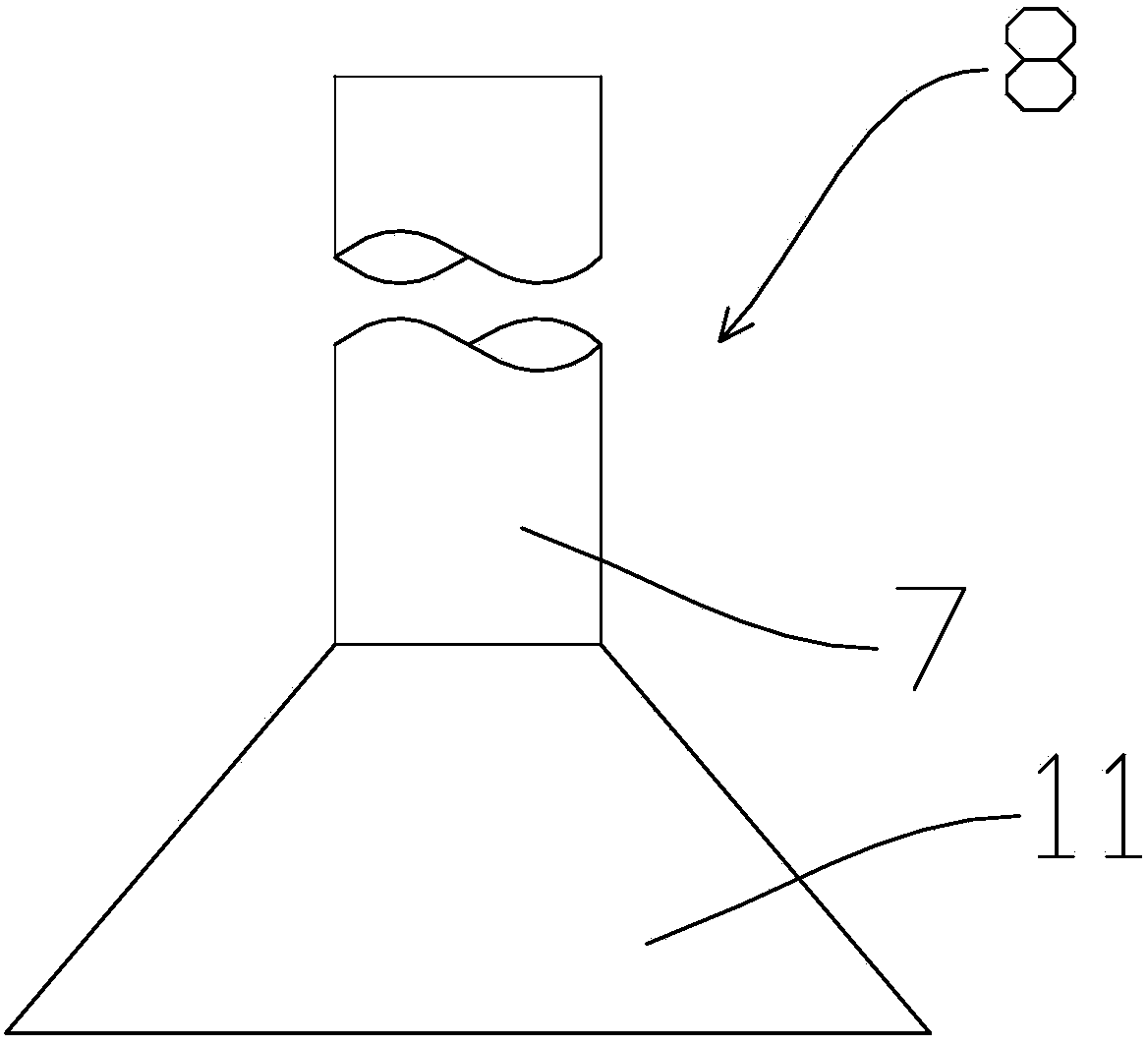

[0066] ②. Coating shortening, conveying the viscous shortening to the roller coating machine, and evenly coating the shortening on the surface of the dough placed on the conveying equipment through the oiling roller. Please refer to Table 1 for the thickness of skin and oil layer.

[0067] ③ Stretch the dough, stretch the coated dough through stretching equipment, the oil layer will form a thin striped oil film attached to the dough with the stretching of the dough, each control parameter and the skin after stretching and stretching See Table 1 for the thickness of the oil film.

[0068] ④, edge trimming, so that the width of the dough is equal to the width of the oil film.

Embodiment 2—4

[0070] Each process step is the same as that in Example 1, except that the coating equipment is a flow-feeding oiler, and the coating is performed through an oil supply nozzle. Please refer to Table 1 for the control parameters of each step, the thickness of the skin and oil layer after coating, and the thickness of the skin and oil film after stretching.

Embodiment 5

[0072] The process steps are the same as in Example 1, except that five-spice powder is added during the pretreatment of the shortening. Please refer to Table 1 for the control parameters of each step, the thickness of the skin and oil layer after coating, and the thickness of the skin and oil film after stretching.

[0073] Table 1 Example 1 to 5 each step control parameters and performance characterization of the produced dough

[0074]

[0075]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com