Iron walnut chopping machine

A technology of iron walnuts and walnut clips, which is applied in the field of iron walnut chopping machines, can solve the problems of different sizes of shell kernel gaps, finger cuts, dangers, etc., and achieve the effects of easy grasp and use, safe and reliable operation, and safety and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

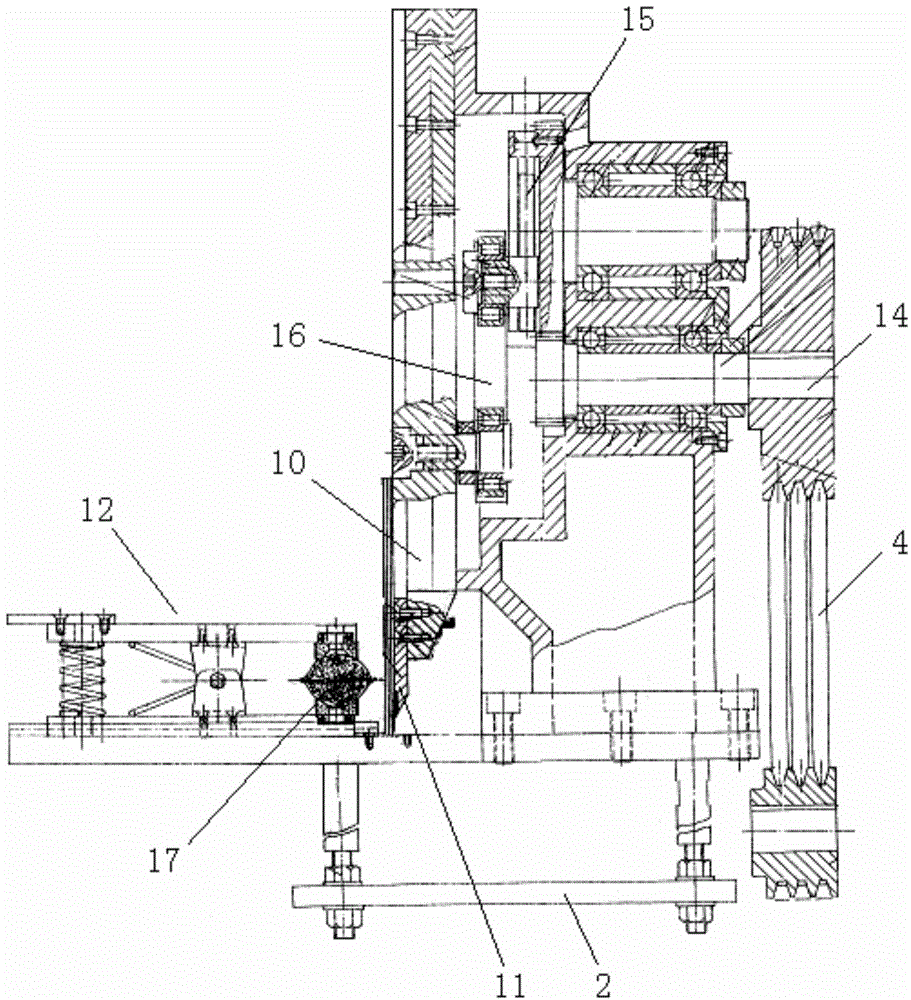

[0026] The present invention will be described in detail below with reference to the above-mentioned drawings.

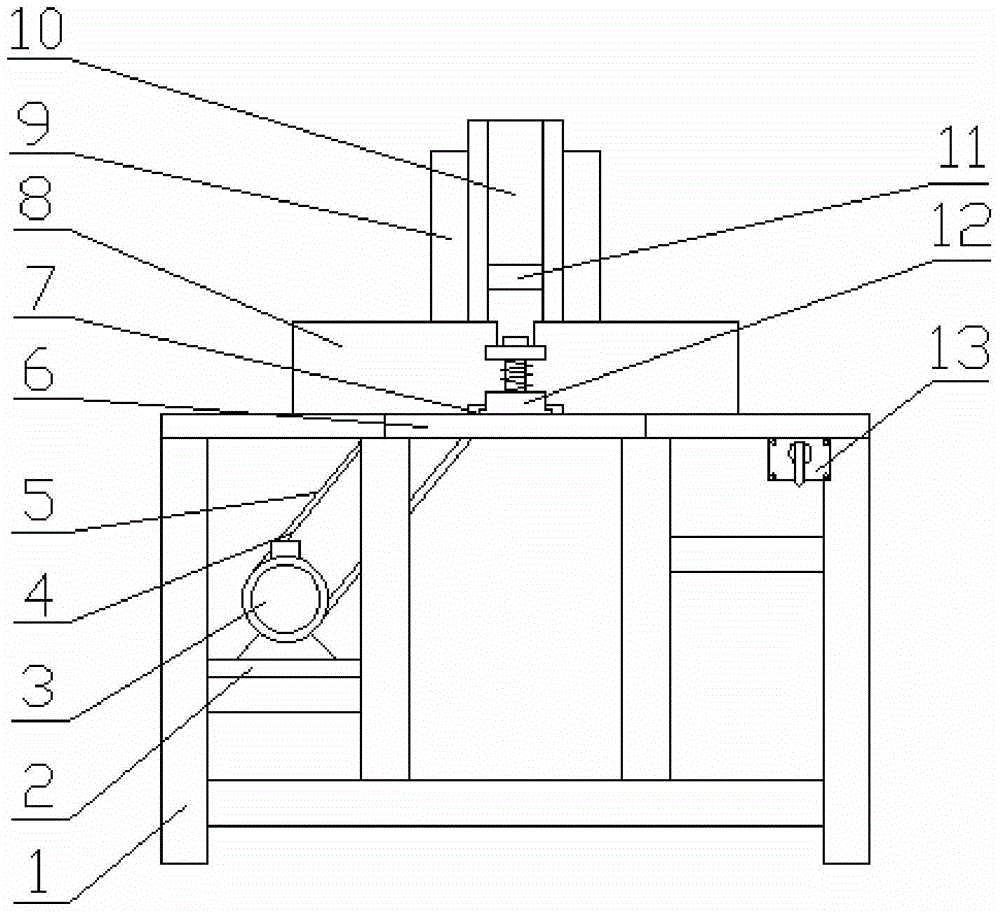

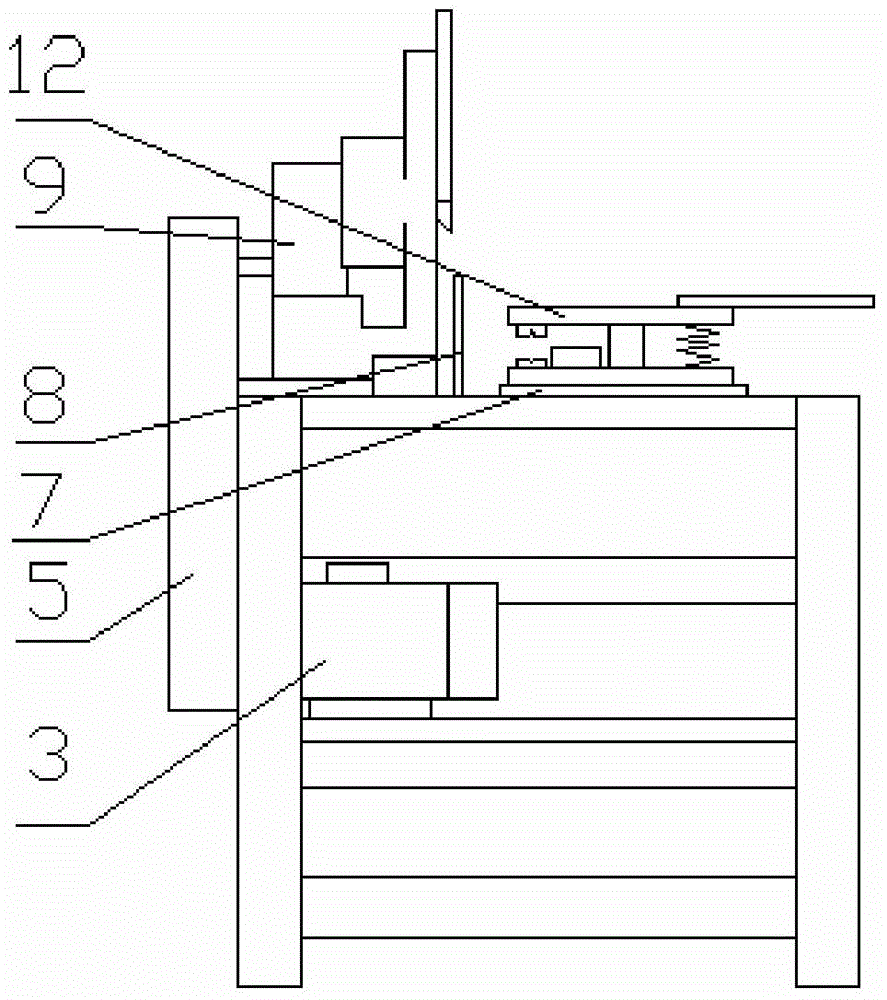

[0027] Such as Figure 1-3 As shown, the iron walnut chopping machine is mainly composed of a frame, a motor, a machine head, a walnut clamping seat and the like. A platform is fixed in the middle of the table top of the frame. The length of the table is equal to the width of the frame. The machine head is installed on the rear of the table surface, and two guide rails are installed on the front. The walnut clamping seat is set on the guide rail. , the walnut clamping seat can move linearly back and forth on the guide rail and the walnut clamping end faces the cutter.

[0028] Main shaft, reduction gear, connecting rod and other components are arranged inside the machine head. The front surface of the machine head is a cutter slider, which moves up and down on the front surface of the machine head. A machine head cover is arranged on the machine head, and the mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com