Dust collection box for duct collector

A technology for dust collection boxes and vacuum cleaners, which is applied in the direction of suction filters, etc., which can solve the problems of cleaning dust and easily damaged Hypa, and achieve the effect of prolonging the service life and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

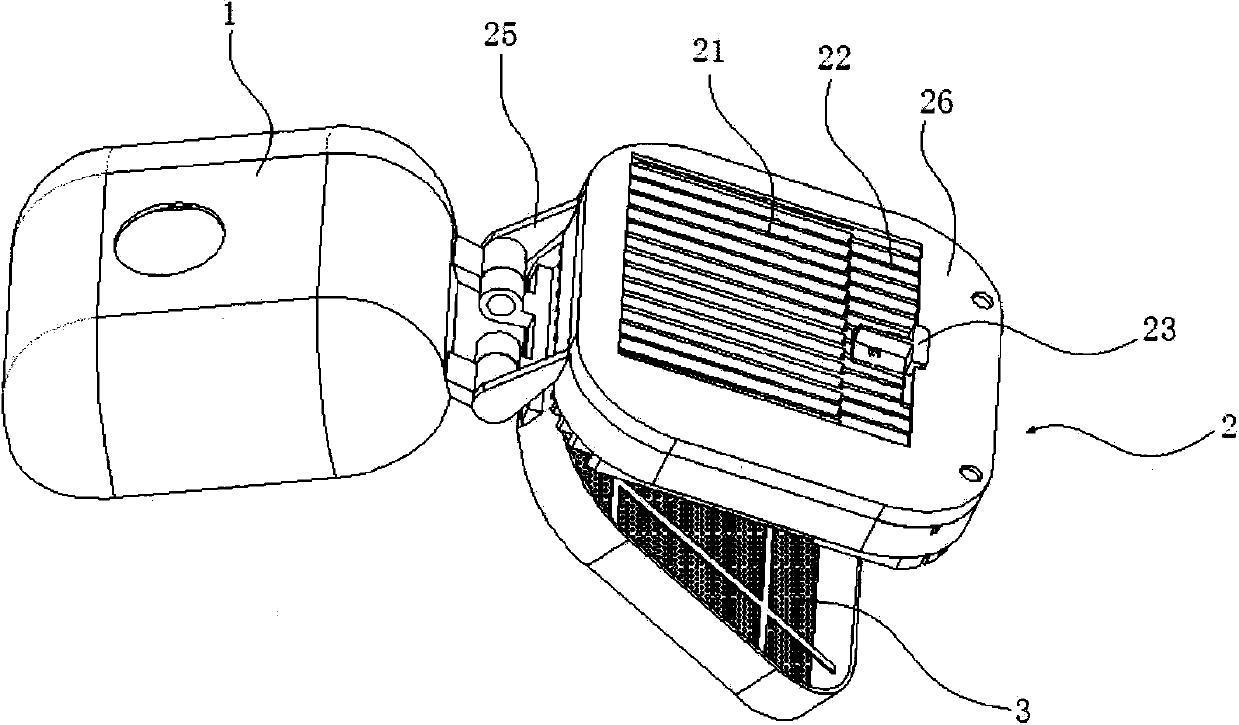

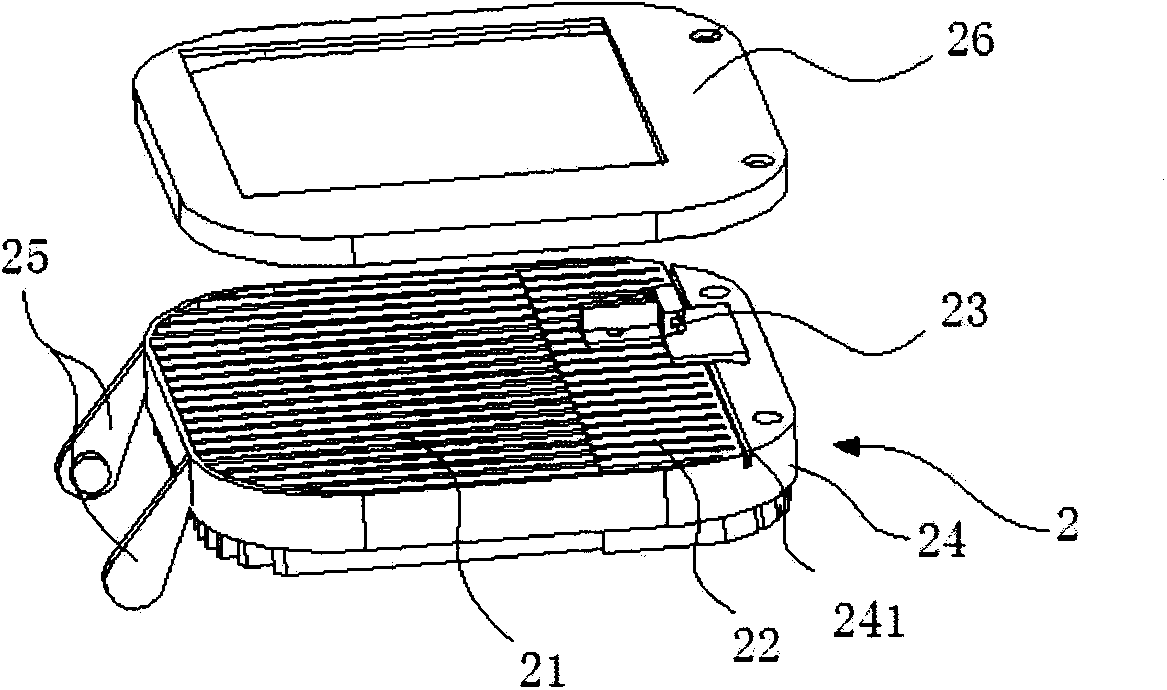

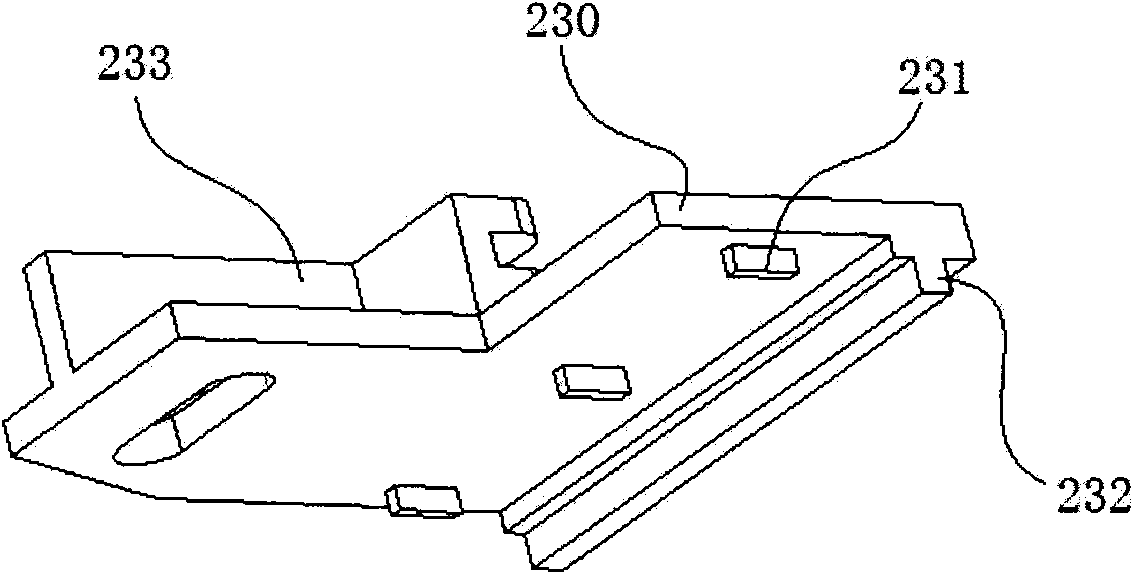

[0020] refer to Figure 1~3 As shown, the dust collecting box of the vacuum cleaner includes: a box cover 1, a Hypa component 2, the box cover 1 is coaxially connected with the Hypa component 2, and the Hypa component 2 includes a Hypa shell 24, which is set Several Hypa strips 21 on the Hypa shell, wherein each Hypa strip 21 ends are provided with ribs 22, corresponding to the ribs 22, a vibration unit 23 is provided, and the vibration unit 23 and The contact end of the rib 22 is provided with at least one flange 231, and the Hypa assembly also includes a gland 26, the gland 26 is used to compress the vibration unit 23, and the vibration unit 23 can be positioned at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com