Device utilizing multi-component liquid to perform mixing and constant-temperature corrosion preventive spraying

An anti-corrosion spraying and multi-component technology, applied in the direction of liquid spraying devices, spraying devices, etc., can solve the problems of unstable coating quality, high labor intensity, low operating efficiency, etc., and achieve difficult cooling and solidification, high coating efficiency, The effect of saving paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

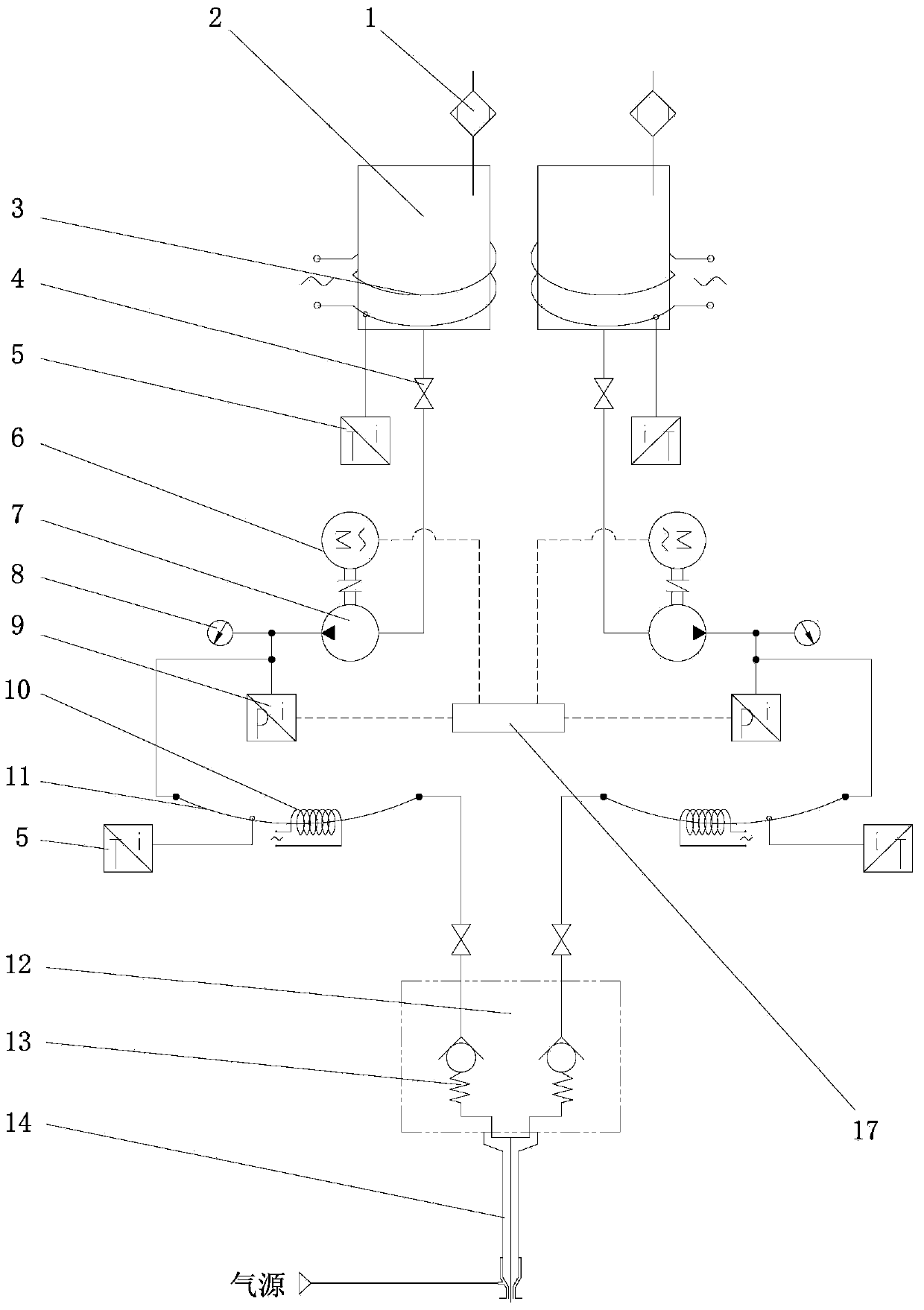

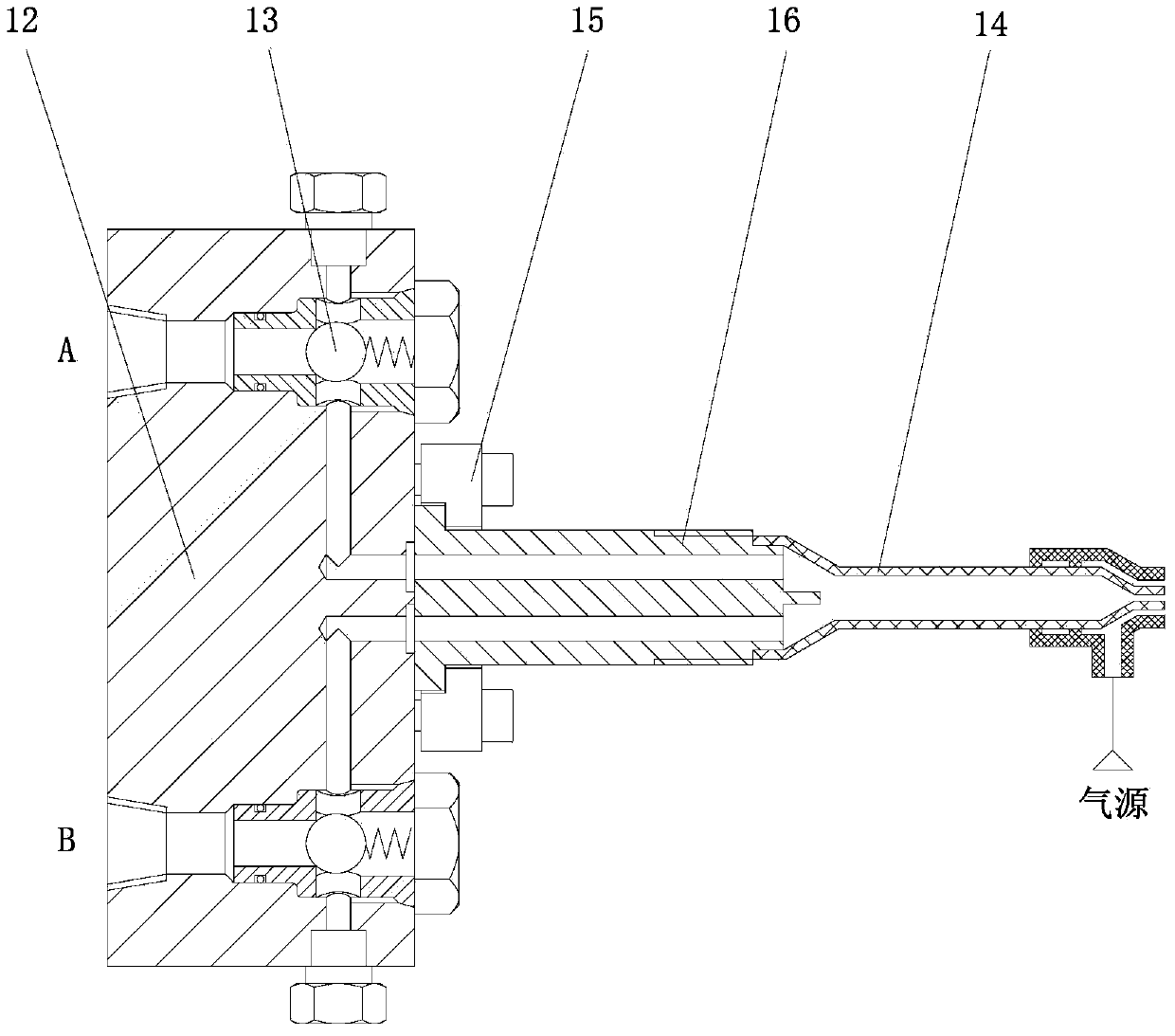

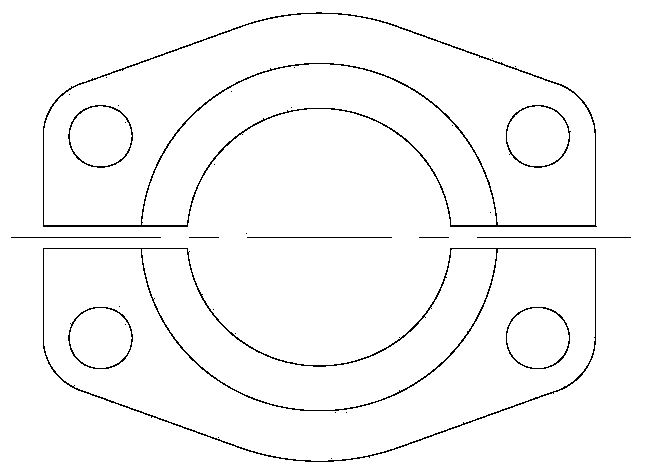

[0022] The invention provides a device for mixing and constant-temperature anticorrosion spraying using multi-component liquids. The device includes at least two groups of feed systems with the same structure, spray gun valve block 12, mixing pipe 14, split flange 15, nozzle seat 16 and frequency conversion controller 17, and the at least two groups of feed systems with the same structure include air Filter 1, feeding barrel 2, constant temperature heating coil of feeding barrel 3, valve 4, temperature sensor 5, AC frequency conversion motor 6, hydraulic pump 7, pressure gauge 8, pressure sensor 9, rubber hose heating coil 10, rubber hose 11 And cartridge check valve 13.

[0023] The at least two groups of feeding systems with the same structure are used for mixing and spraying multiple raw materials. Here, the device may include two groups of feed systems, referred to as A feed system and B feed system, respectively.

[0024] In the following, the device provided by the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com