An automobile floor beam assembly

An automobile floor beam and assembly technology, which is applied to the superstructure sub-assembly, vehicle components, superstructure and other directions, can solve the problems of a large number of parts and components of the floor beam assembly, poor passenger safety protection ability, and unfavorable chassis layout, etc. Achieve the effect of extending the energy transmission path, enhancing the ability of the vehicle to resist collision, and facilitating the overall layout of the vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

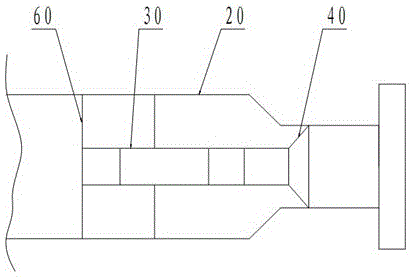

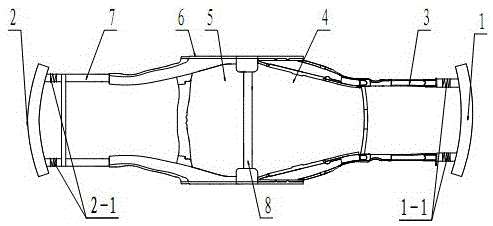

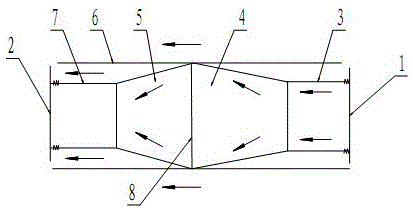

[0020] see figure 2 , the present invention includes a front anti-collision beam 1, a front guide beam 3, a front trapezoidal frame 4, a rear trapezoidal frame 5, a rear guide beam 7 and a rear anti-collision beam 2, the front end of the front anti-collision beam 1 and the front guide beam 3 assembly, the front guide beam 3 is symmetrically arranged left and right, and the front anti-collision beam collapse energy-absorbing structure 1-1 is provided at the assembly position of the front guide beam 3 and the front anti-collision beam 1, and the rear end of the front guide beam 3 is connected to the front The side trapezoidal frame 4 is fixedly connected, the front side trapezoidal frame 4 and the rear side trapezoidal frame 5 are connected as a whole through the middle beam 8, the rear side trapezoidal frame 5 is fixedly connected with the front end of the rear guide beam 7, and the rear guide beam 7 Left and right symmetrical arrangements, the rear end of the rear guide beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com