A polysilicon reduction furnace temperature control and energy saving system and process

An energy-saving system and reduction furnace technology, applied in the field of solar photovoltaics, can solve the problems of ineffective removal of silicon powder in the tail gas pipeline, untimely control of feed flow of trichlorosilane, insufficient use of heat energy, etc., to reach the feed temperature Stable and controllable, reduce energy consumption, and reduce the use of steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

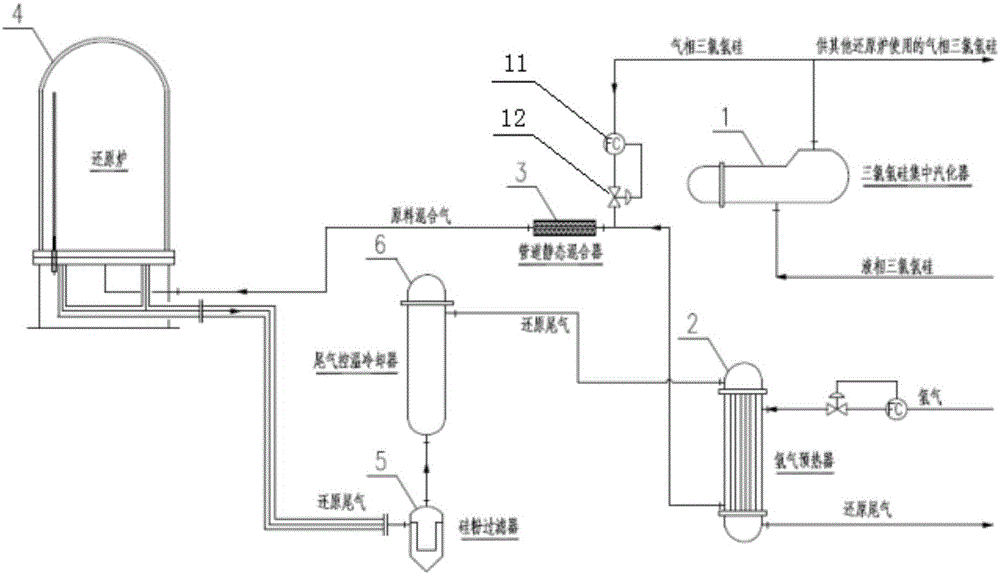

[0059] Embodiment 1: The polysilicon reduction furnace temperature control energy-saving system of the present invention includes a trichlorosilane centralized vaporizer 1, a hydrogen preheater 2, a pipeline static mixer 3, a reduction furnace 4, a silicon powder filter 5, and tail gas temperature-controlled cooling Device 6. The hot hydrogen outlet of the hydrogen preheater 2 tube side is connected to the pipeline static mixer 3, and the gas phase trichlorosilane outlet of the trichlorosilane centralized vaporizer 1 is connected to the hydrogen preheater 2 tube side The hot hydrogen outlet pipe is at the minimum distance from the pipeline static mixer 3; the mixed gas outlet of the pipeline static mixer 3 is connected to the air inlet of the reduction furnace 4; the tail gas outlet of the reduction furnace 4 is connected to the silicon The powder filter 5 inlet, the silicon powder filter 5 outlet is connected to the tail gas temperature control cooler 6 shell side high temper...

Embodiment 2

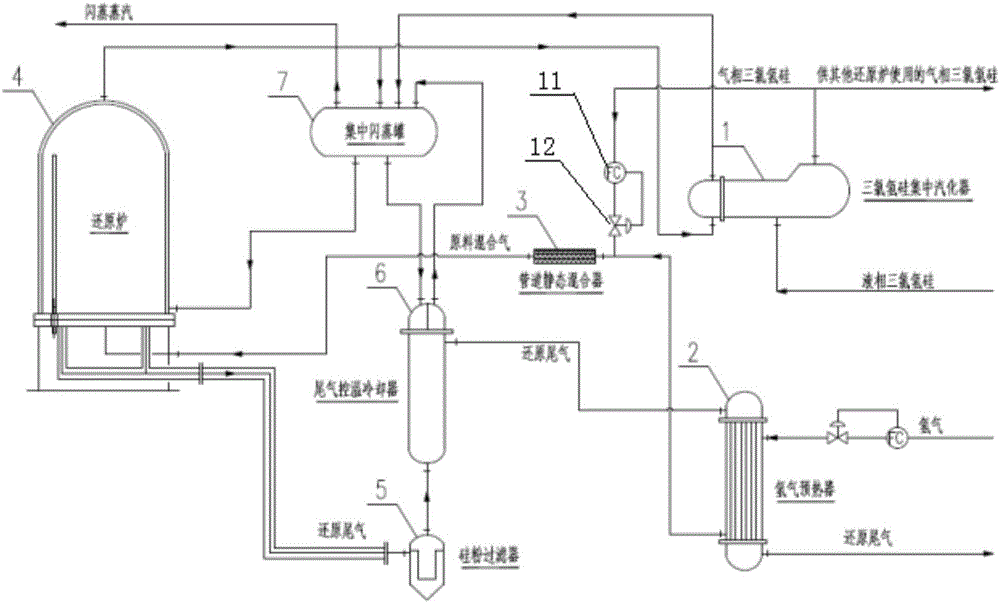

[0060] Embodiment 2: In the further improvement of the present embodiment 1, a centralized flash tank 7 is also included, and the furnace drum cooling water outlet of the concentrated flash tank 7 is connected to the furnace drum cooling water inlet of the reduction furnace 4, and the reduction furnace 4 The furnace cooling water outlet is connected to the concentrated flash tank 7, the furnace cooling water return inlet and the tube side inlet of the trichlorosilane centralized vaporizer 1, and the trichlorosilane centralized vaporizer 1 tube side outlet is connected to the centralized The return water inlet of the flash tank 7, the exhaust cooling water outlet of the centralized flash tank 7 is connected to the inlet of the exhaust gas temperature-controlled cooler 6, and the outlet of the exhaust gas temperature-controlled cooler 6 is connected to the centralized flash tank 7 Exhaust gas cooling water return water inlet.

[0061] The specific implementation method is that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com