High-power piezoelectric material and preparation method thereof

A piezoelectric material and mixing technology, applied in the field of high-power piezoelectric materials and their preparation, can solve the problems that power capacity cannot adapt to the application of high-power ultrasonic equipment, poor mechanical properties, etc., and achieve transgranular fracture and improved mechanical properties. , the effect of reducing tanδ

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

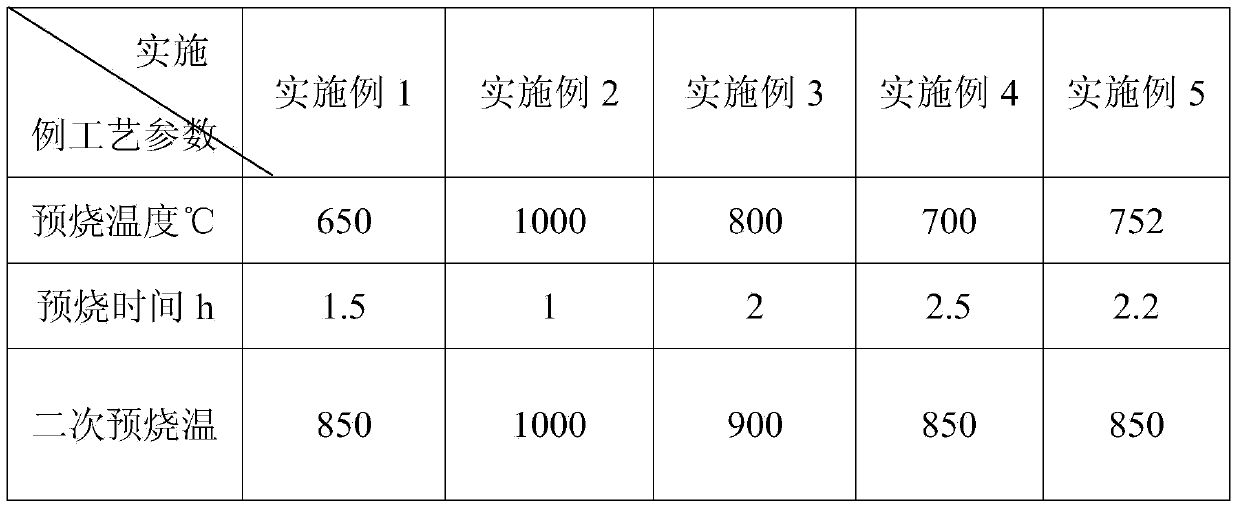

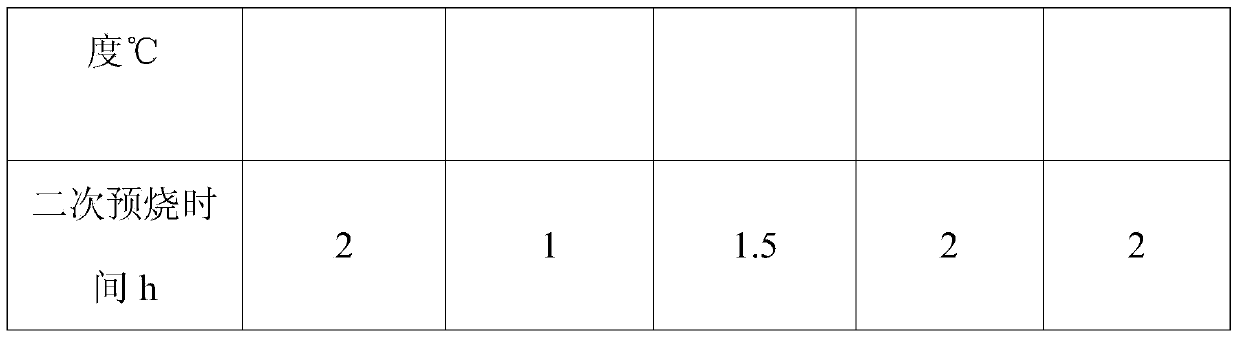

Examples

Embodiment 1

[0049] (1) Dosing according to the chemical composition as described below, pre-briquetting after mixing, pre-calcination, and secondary pre-calcination to obtain substance a;

[0050] (2) The substance a is ball milled, pulverized with D50≤0.7 μm, granulated, molded and then plasticized, then sintered, surface milled, externally rounded and internally rounded to obtain substance b;

[0051] (3) Substance b is subjected to top electrode, polarization and aging treatment to obtain a piezoelectric material.

[0052] The chemical composition of the final piezoelectric material is shown below:

[0053] Pb(Zr 0.45 Ti 0.55 )O 3 +0.015mol%CaFeO 5 / 2 +1 / 10000wt% glass phase+1 / 10000wt%CeO 2

[0054] The mol% and wt% are based on Pb(Zr 0.45 Ti 0.55 )O 3 as the benchmark.

Embodiment 2

[0056] (1) Dosing according to the chemical composition as described below, pre-briquetting after mixing, pre-calcination, and secondary pre-calcination to obtain substance a;

[0057] (2) The substance a is ball milled, pulverized with D50≤0.7 μm, granulated, molded and then plasticized, then sintered, surface milled, externally rounded and internally rounded to obtain substance b;

[0058] (3) Substance b is subjected to top electrode, polarization and aging treatment to obtain a piezoelectric material.

[0059] The chemical composition of the final piezoelectric material is shown in the following formula:

[0060] Pb 1-x Sr x (Zr y Ti 1-y )O 3 +0.095mol%CaFeO 5 / 2 +3 / 10000wt% glass phase+1 / 1000wt%CeO 2

[0061] Wherein, x is 0.1, y is 0.55, and described mol% and wt% are represented by Pb 1-x Sr x (Zr y Ti 1-y )O 3 as the benchmark.

Embodiment 3

[0063] (1) Dosing according to the chemical composition as described below, pre-briquetting after mixing, pre-calcination, and secondary pre-calcination to obtain substance a;

[0064] (2) The substance a is ball milled, pulverized with D50≤0.7 μm, granulated, molded and then plasticized, then sintered, surface milled, externally rounded and internally rounded to obtain substance b;

[0065] (3) Substance b is subjected to top electrode, polarization and aging treatment to obtain a piezoelectric material.

[0066] The chemical composition of the final piezoelectric material is shown in the following formula:

[0067] Pb 1-x Sr x (Zr y Ti 1-y )O 3 +0.055mol%CaFeO 5 / 2 +3 / 1000wt% glass phase+1 / 2500wt%CeO 2

[0068] Wherein, x is 0.05, y is 0.50, and described mol% and wt% are represented by Pb 1-x Sr x (Zr y Ti 1-y )O 3 as the benchmark.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain | aaaaa | aaaaa |

| Piezoelectric strain constant | aaaaa | aaaaa |

| Curie temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com