Damping material for making rail backing plate of high-speed railway and preparation method thereof

A shock-absorbing material and track technology, which is applied in the field of making high-speed rail track backing plate shock-absorbing materials and its preparation, can solve the problems of high cost and low service life, and achieve deformation recovery ability and speed, good shock absorption and buffering Excellent performance and fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

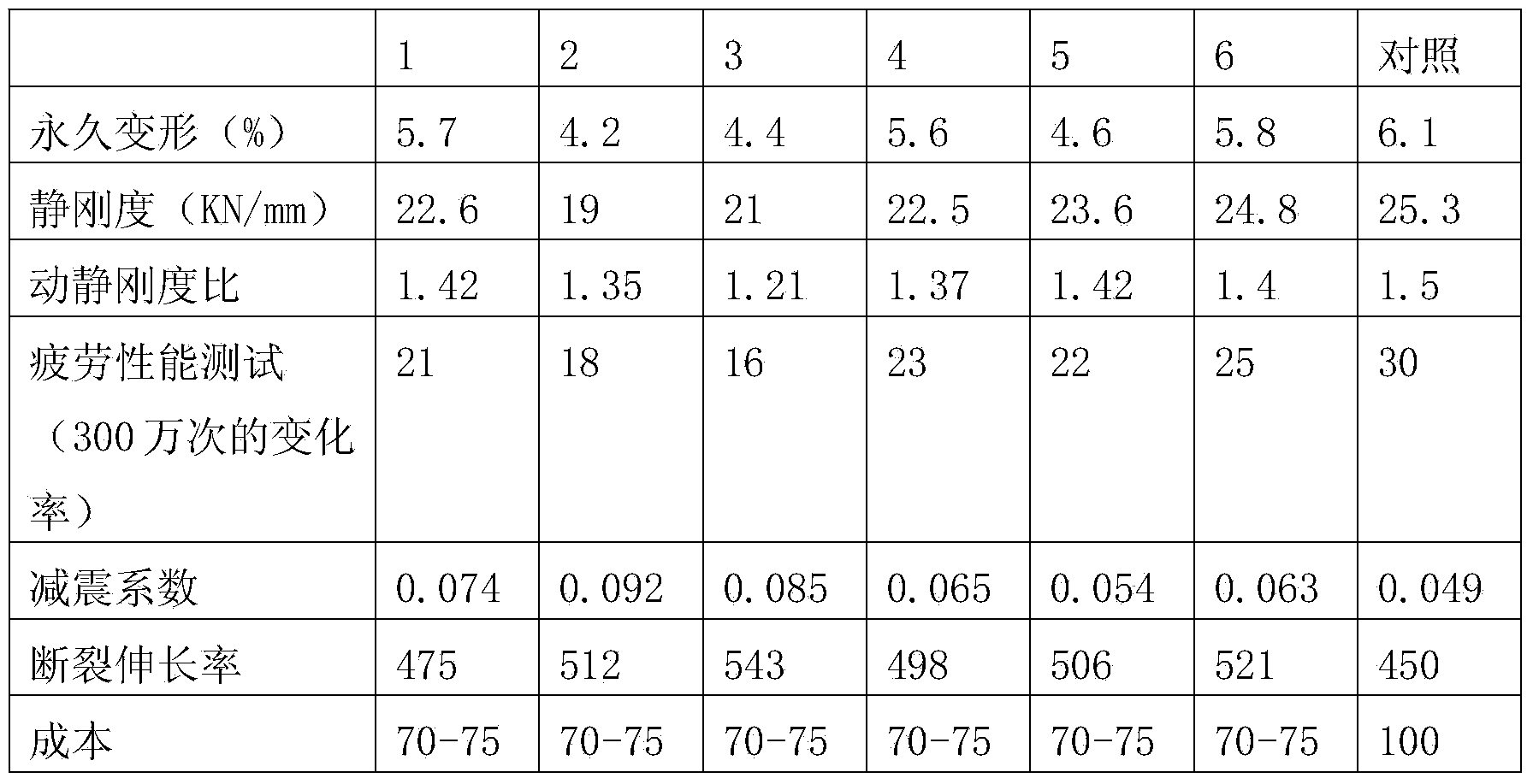

Examples

Embodiment 1

[0019] A shock-absorbing material for making high-speed rail track pads, consisting of the following components in parts by weight:

[0020] 30 parts of phenolic resin, 10 parts of phenol resin, 30 parts of silicone rubber, 10 parts of styrene-butadiene rubber, 15 parts of white carbon black, 2 parts of coupling agent KH5502, 3 parts of cross-linking agent UN5573, 10 parts of stearic acid, benzoyl peroxide 2 parts, cerium sulfate 1, clay 15 parts.

[0021] The above-mentioned preparation method for making the shock-absorbing material of the backing plate of the high-speed rail comprises the following steps:

[0022] Step 1: taking each component by the above parts by weight;

[0023] Step 2: Mix the above components in a high-speed mixer;

[0024] Step 3: Place the uniformly mixed components in the extruder, and melt, mix and extrude them. The process conditions are: the temperature of the first zone is 220 degrees, the temperature of the second zone is 230 degrees, the temp...

Embodiment 2

[0026] A shock-absorbing material for making high-speed rail track pads, consisting of the following components in parts by weight:

[0027] 35 parts of phenolic resin, 12 parts of phenol resin, 40 parts of silicone rubber, 12 parts of styrene-butadiene rubber, 15 parts of white carbon black, 3 parts of coupling agent KH5503, 2 parts of cross-linking agent UN5572, 6 parts of stearic acid, benzoyl peroxide 2 parts, 0.5 parts of cerium sulfate, and 10 parts of clay.

[0028] The above-mentioned preparation method for making the shock-absorbing material of the backing plate of the high-speed rail comprises the following steps:

[0029] Step 1: taking each component by the above parts by weight;

[0030] Step 2: Mix the above components in a high-speed mixer;

[0031] Step 3: Place the uniformly mixed components in the extruder, and melt, mix and extrude them. The process conditions are: the temperature of the first zone is 225 degrees, the temperature of the second zone is 230 ...

Embodiment 3

[0033] A shock-absorbing material for making high-speed rail track pads, consisting of the following components in parts by weight:

[0034] 40 parts of phenolic resin, 12 parts of phenol resin, 35 parts of silicone rubber, 10 parts of styrene-butadiene rubber, 12 parts of white carbon black, 2.5 parts of coupling agent KH550, 2.5 parts of cross-linking agent UN557, 8 parts of stearic acid, over 1.5 parts of benzoyl oxide, 0.8 parts of cerium sulfate, and 12 parts of clay.

[0035] The above-mentioned preparation method for making the shock-absorbing material of the backing plate of the high-speed rail comprises the following steps:

[0036] Step 1: taking each component by the above parts by weight;

[0037] Step 2: Mix the above components in a high-speed mixer;

[0038] Step 3: Put the uniformly mixed components in the extruder, and melt, mix and extrude them. The process conditions are: the temperature of the first zone is 230 degrees, the temperature of the second zone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com