Red high-brightness elastic stress luminescent material and preparation method thereof

An elastic stress, luminescent material technology, applied in luminescent materials, chemical instruments and methods, by measuring the force measurement of changes in optical properties of materials when they are stressed, etc., can solve problems such as not meeting the needs of practical applications and achieve equipment The effect of low requirements, low cost and easy control of conditions

Inactive Publication Date: 2013-12-25

QINGDAO UNIV

View PDF3 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Unfortunately, the elastic stress luminescence intensity of this material is still not comparable to that of ZnS:Mn with strong elasti

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

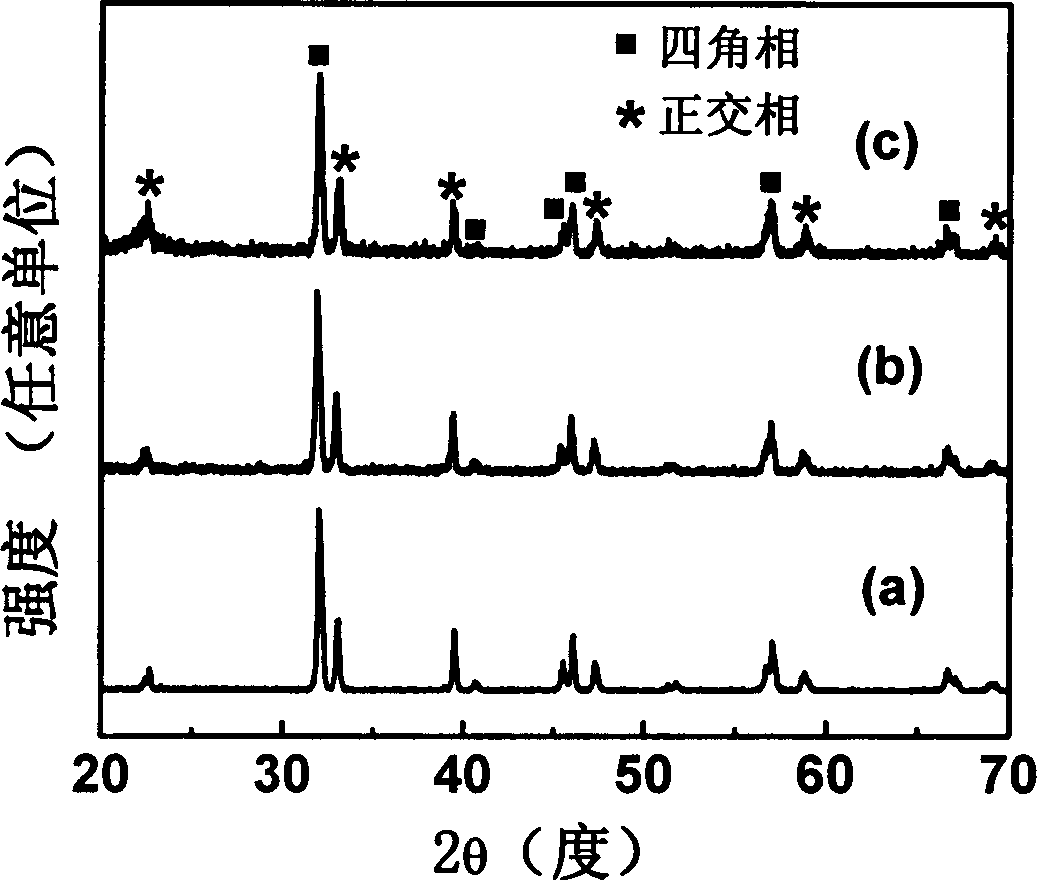

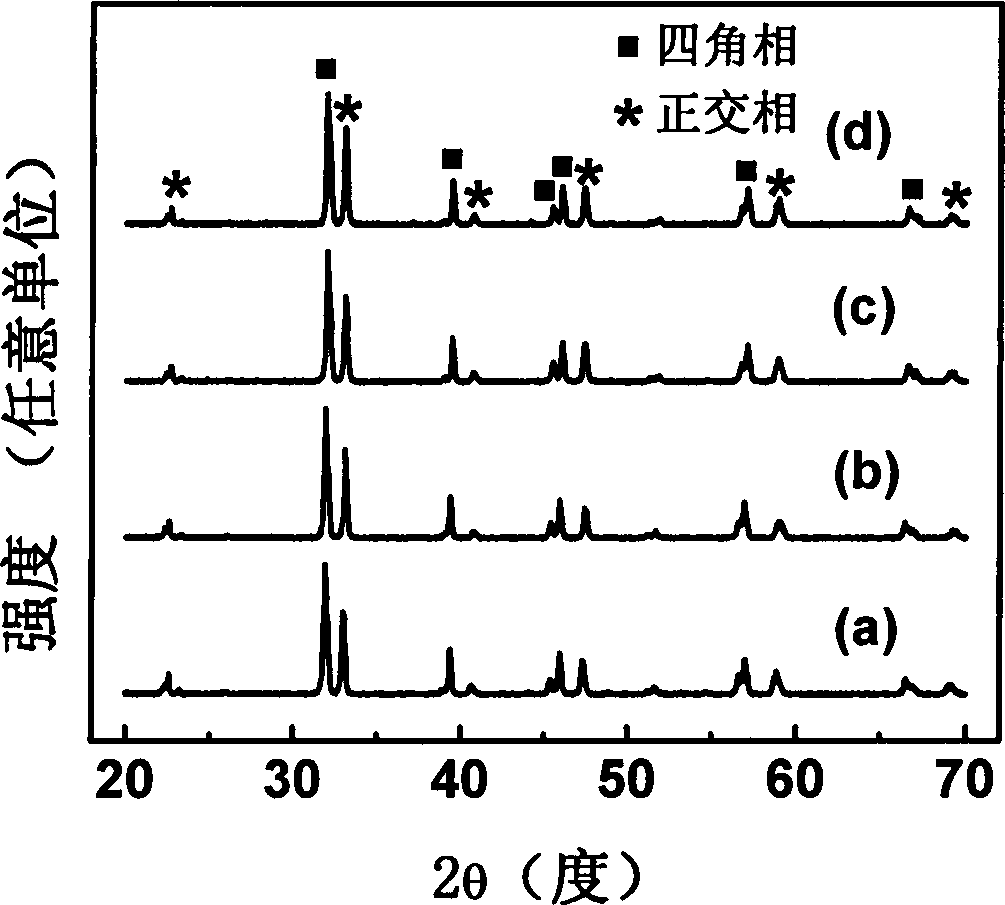

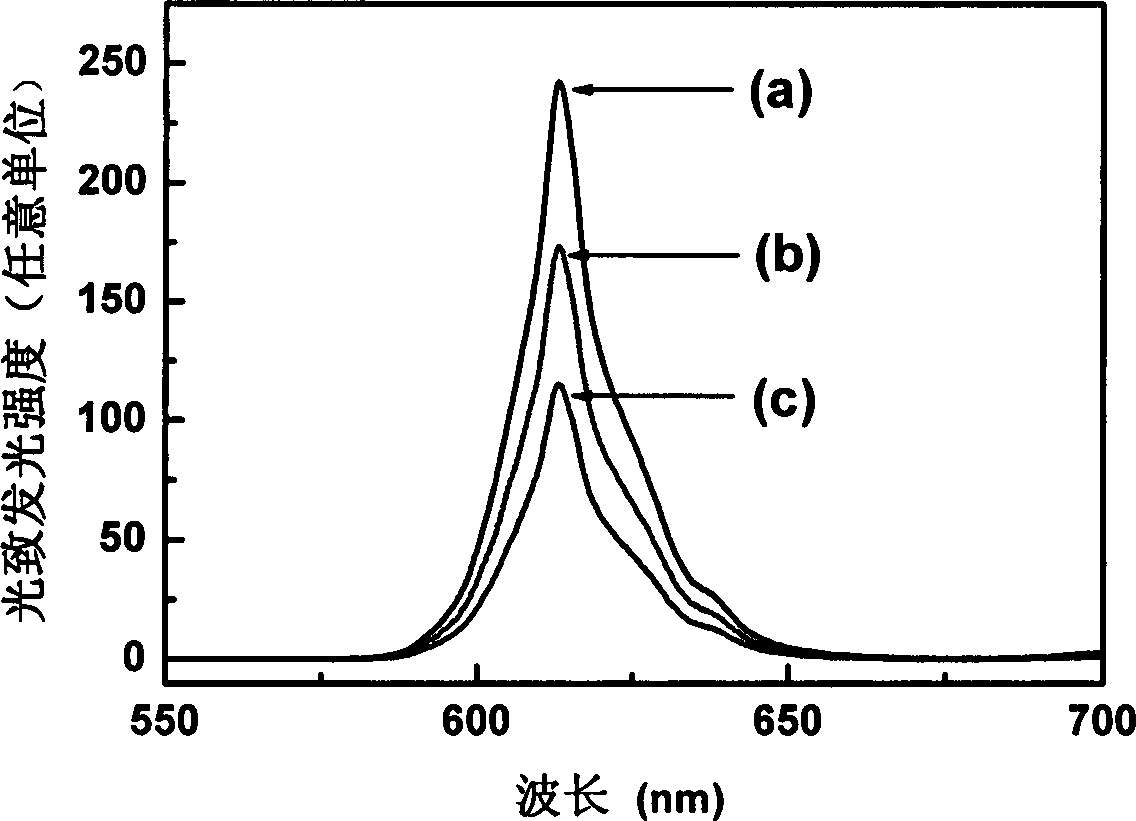

The invention relates to a red high-brightness elastic stress luminescent material and a preparation method thereof. The preparation method is characterized in that a red high-brightness elastic stress luminescent material (Ba, Ca) TiO3:Pr<3+>, Re<3+> (Re<3+> is one or more of Y<3+>, La<3+>, Nd<3+>, Gd<3+>, Yb<3+> and Lu<3+>) is prepared by taking a complex-phase (Ba, Ca) TiO3:Pr<3+> material as a matrix and using a method for co-doping one or more of trivalent rare earth ions Y<3+>, La<3+>, Nd<3+>, Gd<3+>, Yb<3+> and Lu<3+> and a trivalent rare earth ion activating agent Pr<3+>. The red high-brightness elastic stress luminescent material and the preparation method thereof have the advantages: (1) the preparation method of the material is simple, easy to operate and low in equipment requirement; (2) the prepared material (Ba, Ca) TiO3:Pr<3+>, Re<3+> is relatively strong in elastic stress luminescence, clear and macroscopic in elastic stress luminescence brightness at dark places, rapid in stress luminescence afterglow attenuation, free of macroscopic stress luminescence glows and stress tracks and capable of being widely applied to the fields such as real-time stress distribution detection, stress sensors, displays, entertainment devices and the like for living bodies, mechanical parts, buildings and the like; (3) the raw materials Ba, Ca and Ti of a material system are all rich elements on the earth and belong to environment-friendly materials.

Description

technical field [0001] The invention belongs to the scientific and technical field of stress luminescent functional materials, and relates to a red high-brightness elastic stress luminescent material (Ba, Ca)TiO 3 : Pr 3+ , Re 3+ and its preparation method. The elastic stress luminescent material activates the alkaline earth metal titanate inorganic compound (Ba, Ca)TiO with trivalent praseodymium ions 3 : Pr 3+ as the matrix, by co-doping trivalent rare earth ions Y 3+ , La 3+ 、Nd 3+ 、Gd 3+ , Yb 3+ or Lu 3+ One or more of the methods to prepare. The red high-brightness elastic stress luminescent material prepared by the method of the invention can significantly improve the elastic stress luminous intensity of the material in practical application. Background technique [0002] Stress luminescent material is a solid material that can directly convert mechanical energy into light energy, that is, the material emits light due to deformation when different mechanical...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C09K11/67G01L1/24

Inventor 张君诚龙云泽张红娣

Owner QINGDAO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com