One-bath dyeing method of trilobal dyeable modified polyester/cotton blended fabric with high cationic content

A technology for modifying polyester and dyeing methods, applied in dyeing methods, textiles and papermaking, etc., can solve the problems of high price, unfavorable health and environmental protection of anti-precipitation additives, and few varieties of cationic dyes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

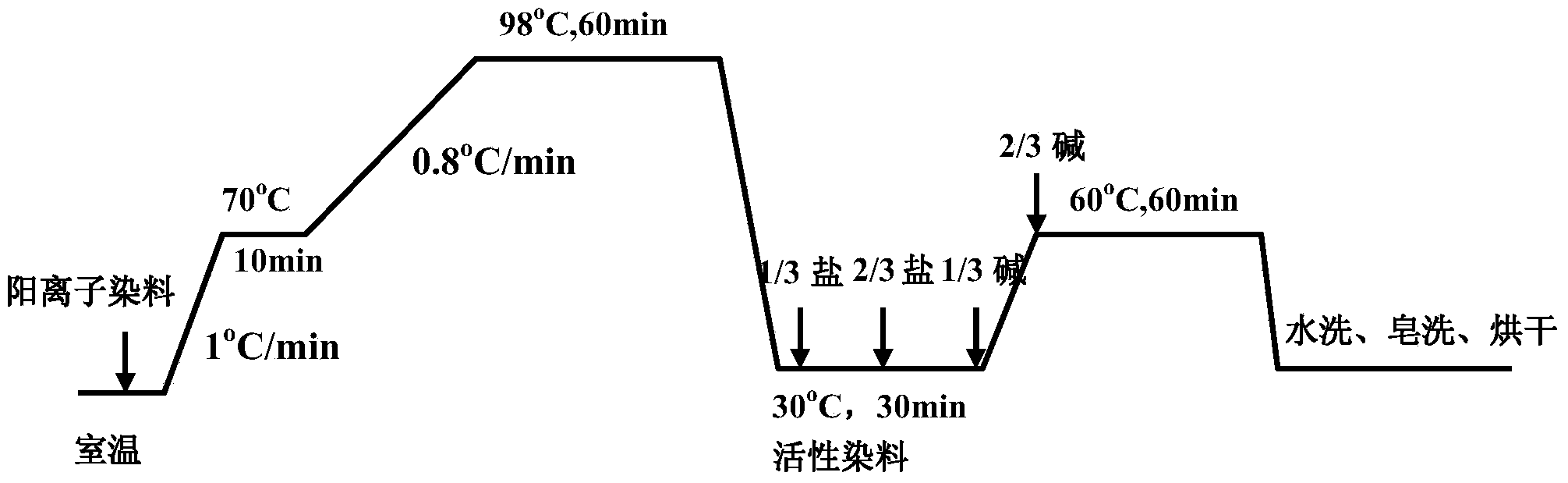

[0080] After pretreatment, the modified polyester / cotton blended knitted jersey (80 / 20) was immersed in cationic red X-GRL1.5% (o.w.f.), sodium acetate 0.3% (o.w.f.) and acetic acid 0.35% (o.w.f.) to adjust the pH at 4 ~5, in a cationic dyeing bath with a bath ratio of 1:15. According to the dyeing temperature process curve ( figure 2 ) for cationic dyeing, and then add reactive red DSW 4.5% (o.w.f.) for cotton part dyeing. Determination of apparent depth K / S value, unevenness S and color fastness, the results are shown in Table 1.

[0081] Table 1 dyeing performance test results

[0082]

Embodiment 2

[0084] Modified polyester / cotton / spandex blended knitted jersey (65 / 35) is immersed in cationic red X-GRL1.5% (o.w.f.), sodium acetate 0.3% (o.w.f.) and acetic acid 0.35% (o.w.f.) to adjust the pH at 4-5 , in a cationic dyeing bath with a bath ratio of 1:15. According to the dyeing temperature process curve ( figure 2 ) for cationic dyeing, and then add reactive red DSW4% (o.w.f.) for cotton part dyeing. Determination of apparent depth K / S value, unevenness S and color fastness, the results are shown in Table 2.

[0085] Table 2 dyeing performance test results

[0086]

Embodiment 3

[0088] Modified polyester / cotton / spandex blended knitted jersey (35 / 65) was immersed in cationic red X-GRL1% (o.w.f.), sodium acetate 0.3% (o.w.f.) and acetic acid 0.35% (o.w.f.) to adjust the pH at 4-5, bath Ratio of 1:15 in the cationic dye bath. According to the dyeing temperature process curve ( figure 2 ) for cationic dyeing, and then add reactive red DSW4.5% (o.w.f.) for cotton part dyeing. Determination of apparent depth K / S value, unevenness S and color fastness, the results are shown in Table 3.

[0089] Table 3 dyeing performance test results

[0090]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com