Stamping device civil engineering installation level control device and installing method

A technology of stamping equipment and control devices, which is applied in the field of levelness control devices for civil installation of stamping equipment, which can solve the difficulties of remediation, displacement of buried slabs, poor control of buried slab plane levelness tolerances of buried slab plane levelness height difference support and other problems, to achieve the effect of simple construction control, reduction of construction errors, and clear design methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

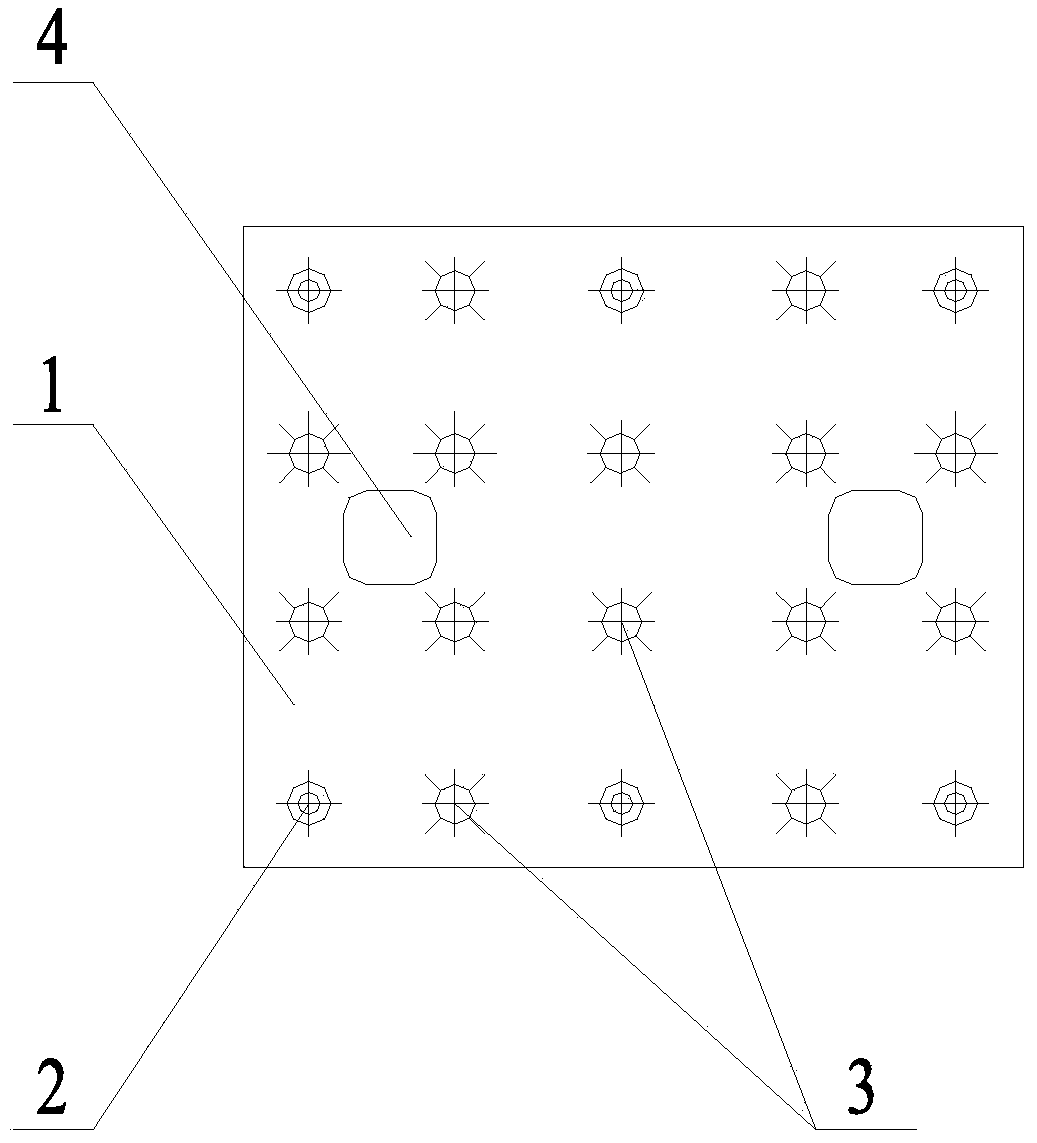

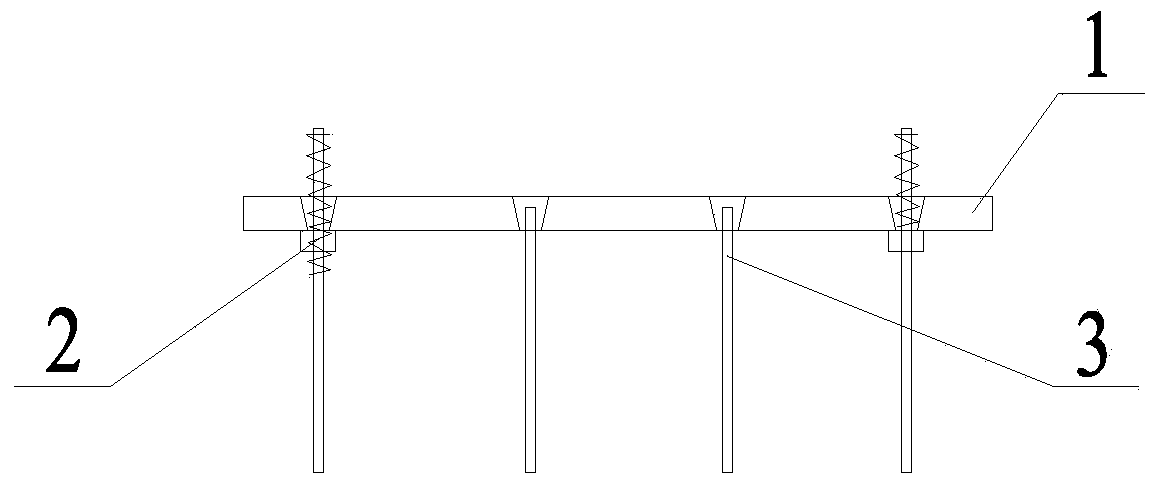

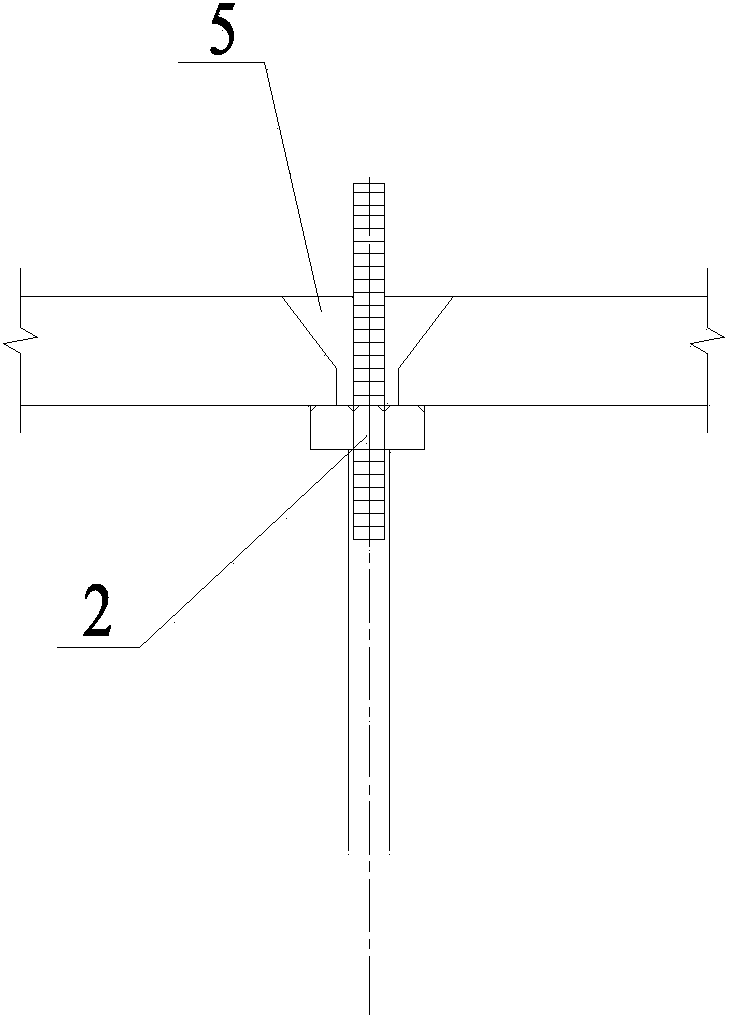

[0027] Such as figure 1 — Figure 5 As shown, a levelness control device for civil installation of stamping equipment, which includes a support embedded plate 1 with a grouting hole 4 and a plug welding hole 5, and a leveling anchor bar 2 and a fixed anchor bar welded in the plug welding hole 5 3. The diameter of the outer end of the plug welding hole 5 is larger than the diameter of the inner end, and the section of the plug welding hole 5 is tapered. The adjusting anchor ribs 2 are welded in the plug welding holes 5 around the edge of the support embedded plate 1, and the fixed anchor ribs 3 are evenly welded in the plug welding holes 5 in the middle of the support embedded plate 1.

[0028] A civil installation method for st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com