Pre-stress carbon-fiber deformed steel bar strengthening structure for refrigeration storage structure nodes and method for producing strengthening structure

A technology of threaded steel bars and structural nodes, applied in the direction of structural elements, building reinforcements, building components, etc., can solve the problems of reducing the seismic performance of cold storage, not improving the seismic performance, affecting the structural integrity of the storage body, etc., to improve the connection Poor performance, strengthening nodes, enhancing overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

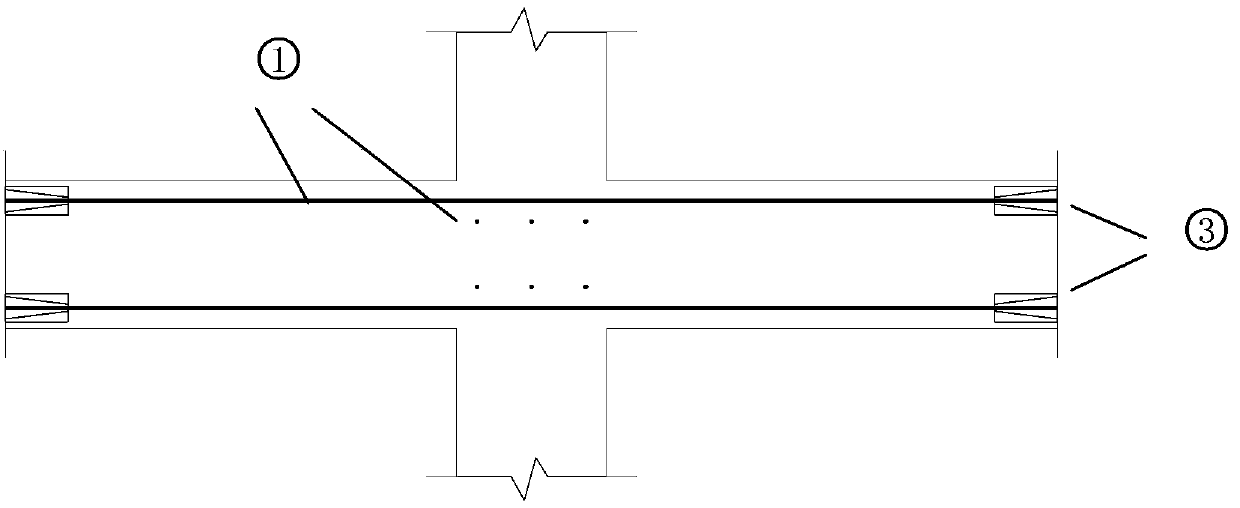

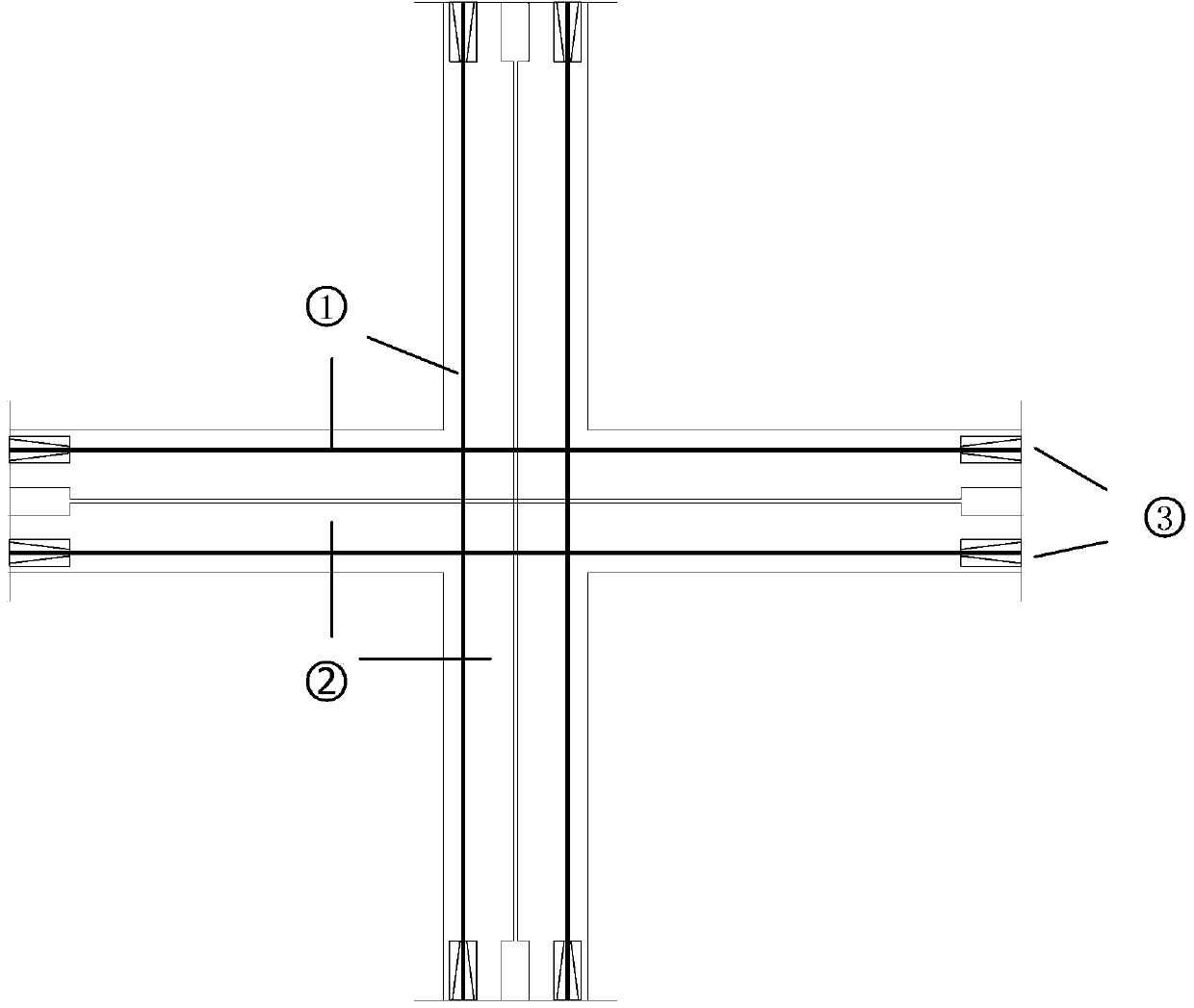

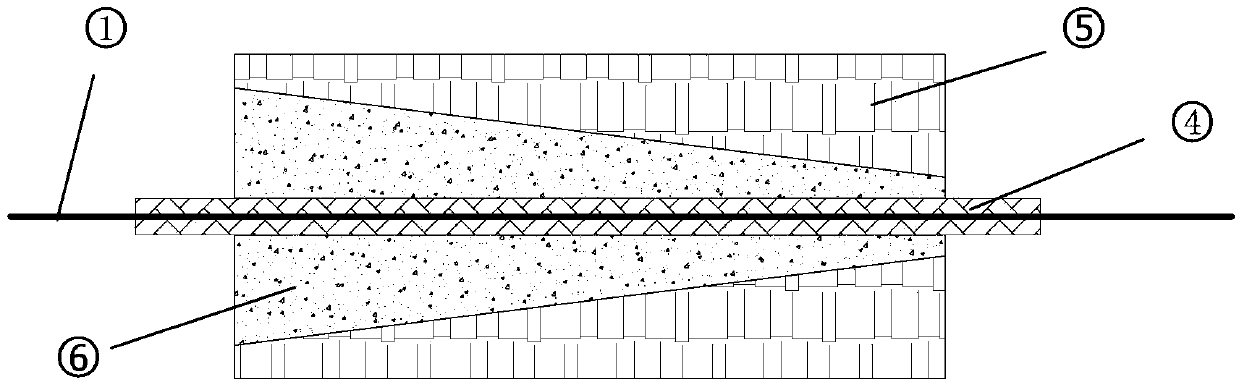

[0047] Embodiment 1, the prestressed carbon fiber threaded steel reinforcement structure of the structural node of the prefabricated cold storage, see Figure 1-Figure 5 : The joint strengthening method includes prestressed carbon fiber threaded steel bar 1, prefabricated metal sleeve 2, clip bonded anchor 3, high damping silicone rubber concrete 4, anchor ring 5, and clip 6. During the fabrication of prefabricated beams and columns, clip-bonded anchors 3 and prefabricated metal sleeves 2 are placed at designated positions. After the prefabricated beam and prefabricated column are assembled, carbon fiber threaded steel bar 1 is placed in the prefabricated metal sleeve 2, and the two ends of the carbon fiber threaded steel bar 1 extend out of the prefabricated beam and bend at an angle, so that it is convenient to use common front clamping jacks at both ends. Pulling, so that the carbon fiber threaded steel bar 1 forms prestress, and at the same time inject the low-temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com