Mounting structure for easily-detached indoor glass decoration surface

A decorative surface, inner glass technology, applied in building construction, covering/lining, construction, etc., can solve the problems of inconvenient installation, use and maintenance, inconvenient replacement and maintenance, large construction space, etc., to achieve convenient replacement and maintenance. Convenience and space saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

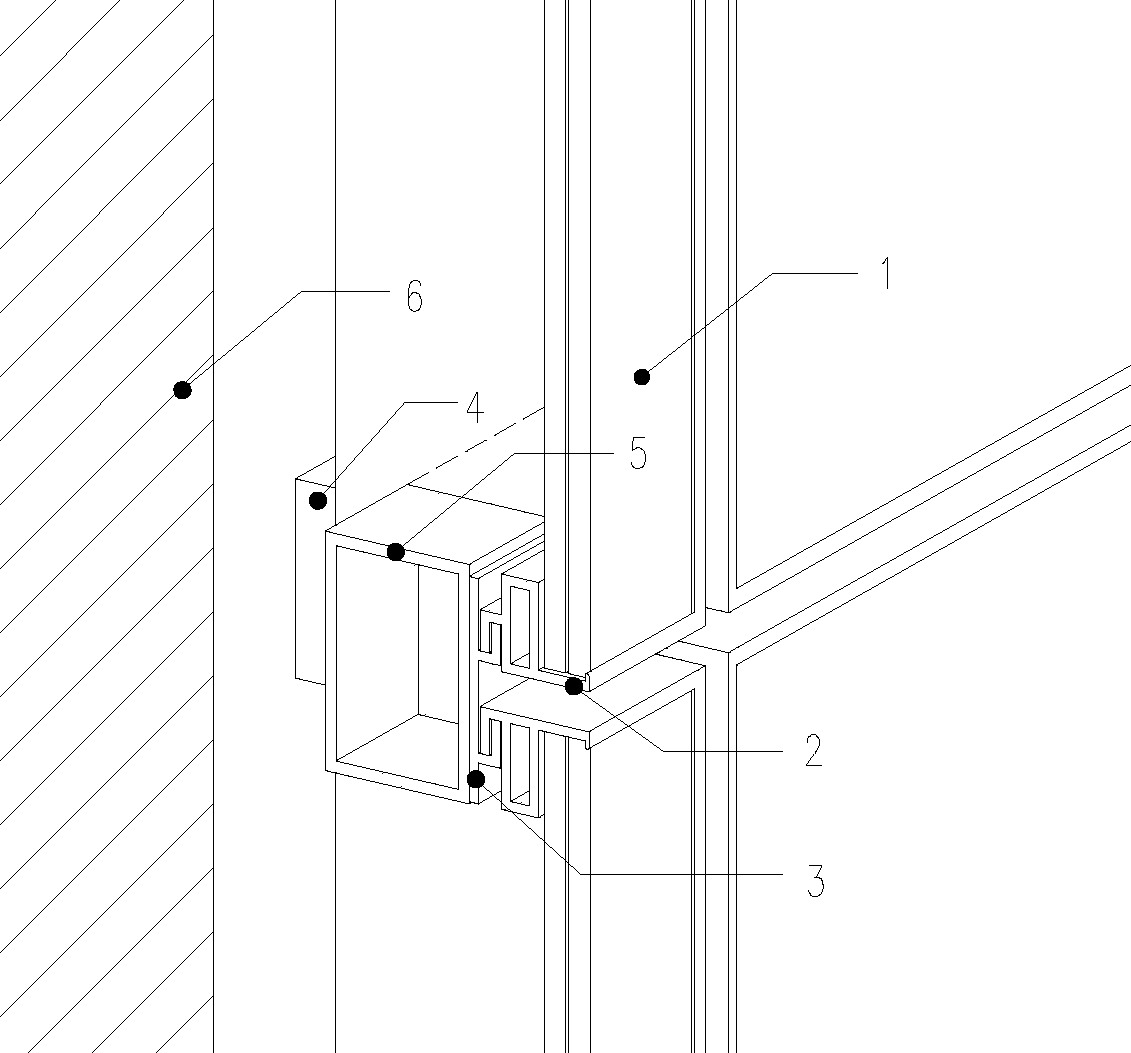

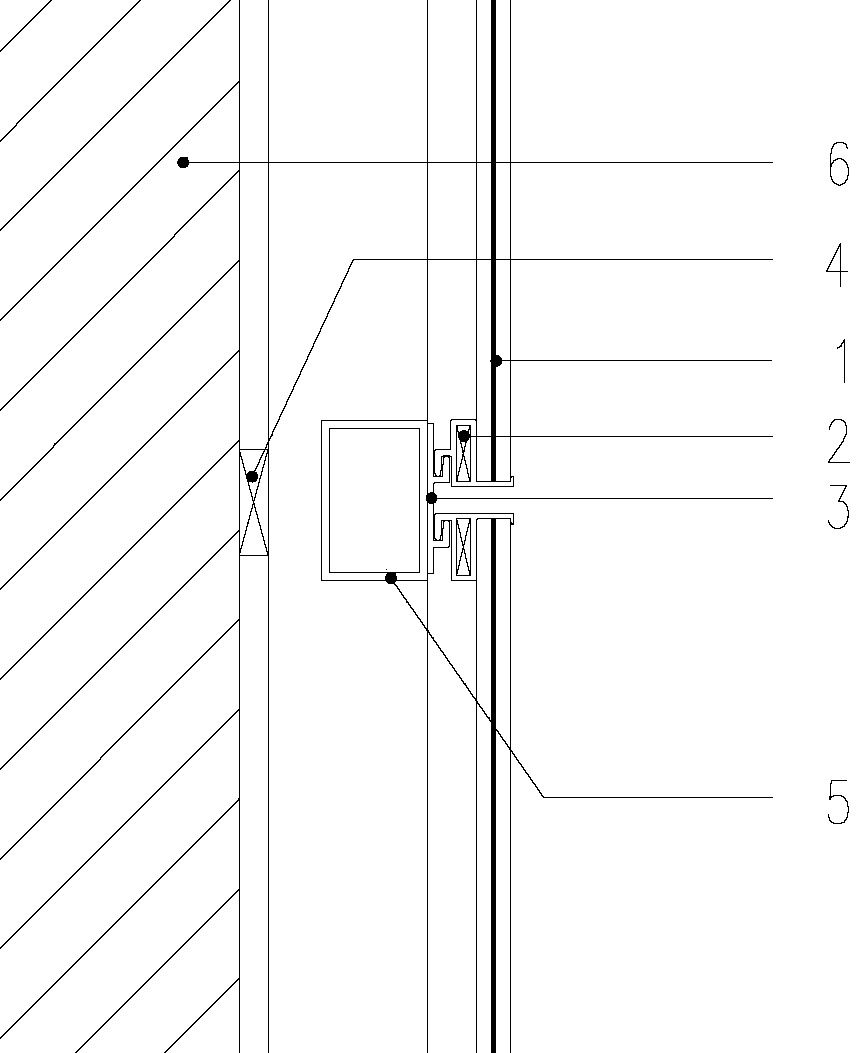

[0011] Such as figure 1 and figure 2 As shown: the polygonal glass 1 and the edge aluminum alloy frame 2 are glued together to form a glass decorative surface unit, the upper and lower frame keel sides of the edge aluminum alloy frame 2 are provided with lower hanging grooves that open downward, and the aluminum alloy back The side of frame 3 is provided with the upper hanging groove of opening upwards. During installation, the edge aluminum alloy frame 2 is hung into the upper notch of the aluminum alloy back frame 3 through the lower notch, forming a firm and safe plug-in installation form, and at the same time, a notch with a controllable width is naturally formed. The aluminum alloy back frame 3 is fixed on the steel frame keel 5 of the building, and the steel frame keel 5 of the building is fixed on the base wall 6 through the aluminum alloy connector 4 .

[0012] The present invention can be applied to any general-purpose glass type, and the processing method of glass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com