Concrete chimney dismantling method

A technology for chimneys and operating platforms, applied to building types, buildings, towers, etc., can solve problems such as unsatisfactory construction progress, low work efficiency, and large engineering volume, and achieve simple and easy-to-operate demolition methods, high work effects, and avoid waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0042] The invention firstly discloses a device for removing a concrete chimney, and secondly discloses a method for removing a concrete chimney by using the device.

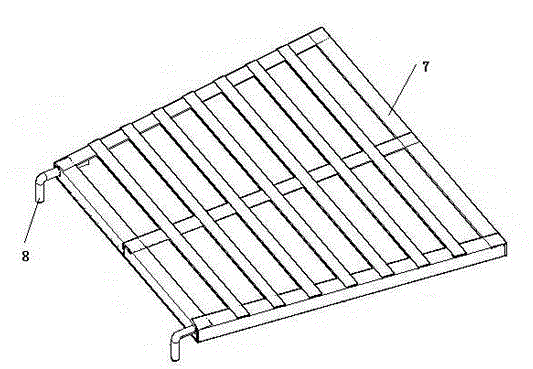

[0043] The removal device includes a positioning mechanism, an operating platform and a hoisting mechanism.

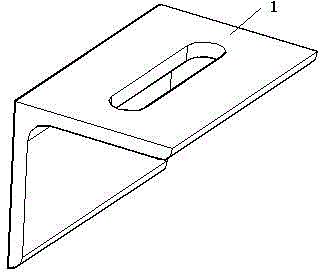

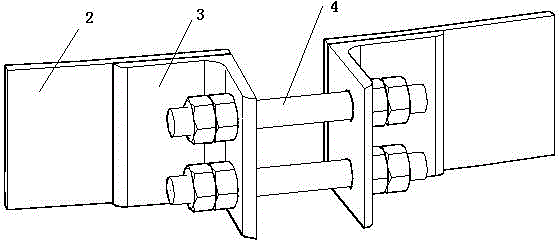

[0044] The positioning mechanism includes a hoop 2, a connecting head 3 and a hanging ear 1. The hoop is a circular structure composed of multiple arc-shaped plates, such as image 3 As shown, the preferred number of initial segments is two, and connectors are provided at the interface of adjacent arc-shaped plates. A plurality of hanging ears are uniformly arranged on the outer wall of the hoop. In this example, if figure 2 As shown, the connector includes two angle steels respectively fixed at the free ends of the hoop interface, one side of which is fixed to the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com