A heavy-duty silent hinge

A heavy-duty, silent technology, applied in the field of hinges, can solve the problems of reducing hinge life, producing loud noises, and large frictional resistance, etc., and achieves the effects of compact and reasonable hinge structure, improved silence, and small frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

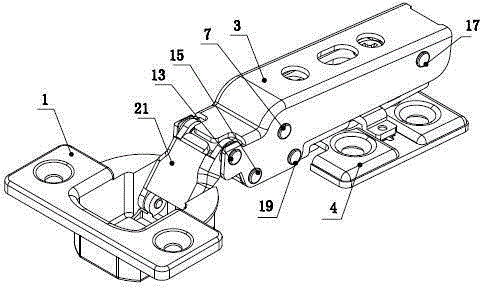

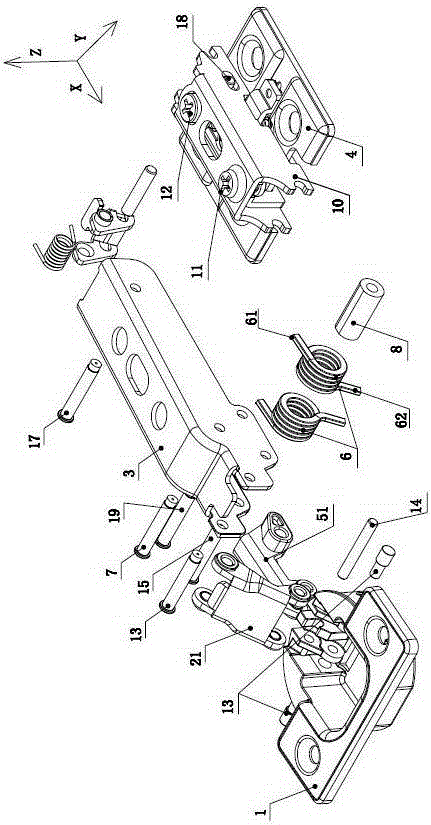

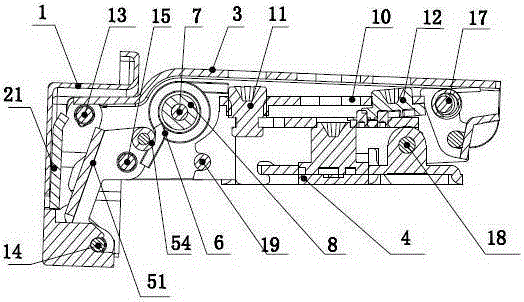

[0029] The structure of the heavy-duty silent hinge of the present invention is as follows: figure 1 , 2 , 3, 4, 9, including the hinge cup 1, the connecting rod assembly 2, the hinge arm 3, the base 4, the crankshaft assembly 5, the fixed arm 10, the moving arm 16 and the elastic member 6 that makes the hinge cup 1 have closing force , The elastic member 6 of this embodiment is a torsion spring. The hinge arm 3 is placed above the base 4, the fixed arm 10 and the movable arm 16 are placed between the base 4 and the hinge arm 3, and the fixed arm 10 is located below the movable arm 16. The arm 16 is connected so that the hinge arm 3 will not move along the X-axis direction relative to the movable arm 16. The movable arm 16 is connected with the fixed arm 10 through the connecting shaft 18, and the connecting shaft 18 passes through the hole 41 on the base 4 to connect the base 4 Connected with the fixed arm 10, the movable arm 16 drives the hinge arm 3 to move along the X-ax...

Embodiment 2

[0036] The structure of the heavy-duty silent hinge of this embodiment is similar to that of Embodiment 1. One of the differences is that the above-mentioned crankshaft assembly 5 is composed of a crankshaft 51, a crankshaft bushing 52, and a crankshaft fixing bushing 53. Compared with Embodiment 1, the torque is reduced. The spring retainer 54 and the fixed shaft 55, the first and second protruding ends 61, 62 of the torsion spring are respectively pressed on the hinge arm 3 and the crankshaft 51; the second difference: the first protrusion 911 and the first groove 912 The set positions are exchanged, the positions set by the second protrusion 921 and the second groove 922 are exchanged, that is, the first groove 912 is set on the outer side wall of the connecting rod sleeve 22, and the first protrusion 911 is set On the hole wall of the first hinge hole 211 ; the second groove 922 is set on the outer wall of the crankshaft sleeve 52 , and the second protrusion 921 is set on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com