Dental restoration fatigue testing machine

A technology of fatigue testing machine and dental prosthesis, applied in the field of fatigue testing machine, can solve problems such as inability to estimate, lack of experimental basis, fracture, etc., and achieve the effect of reasonable design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

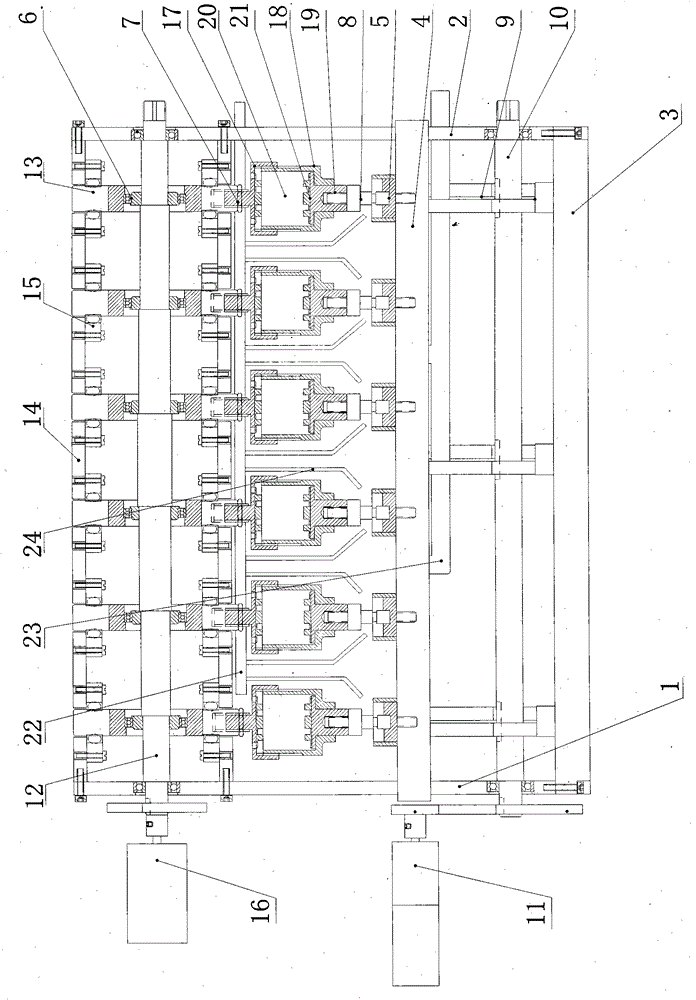

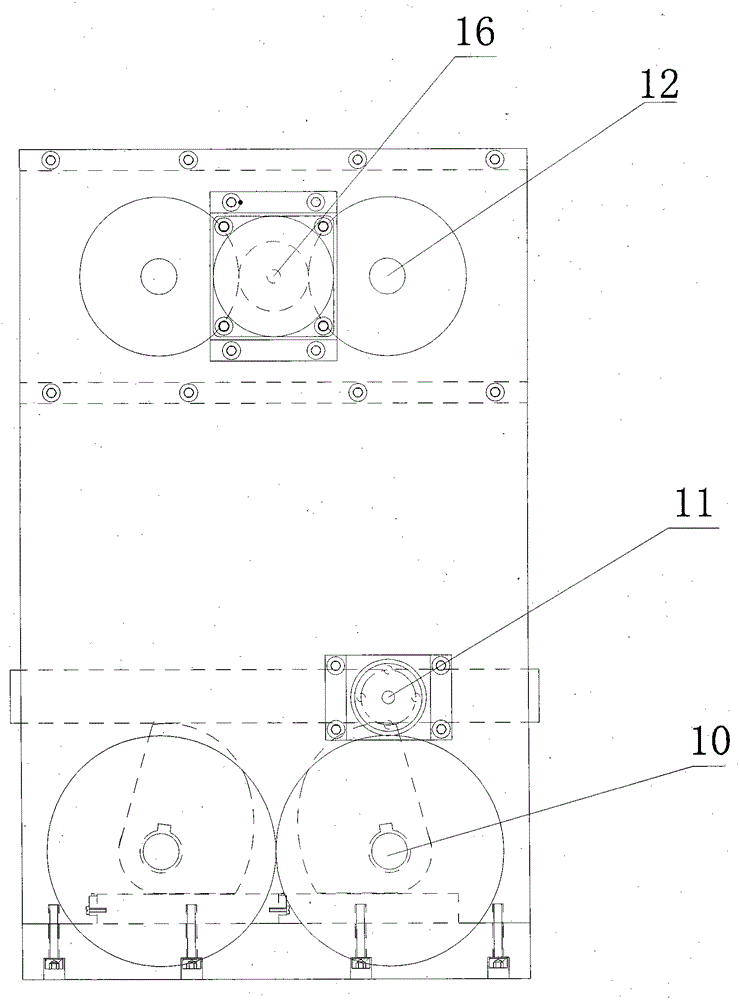

[0016] Such as figure 1 with figure 2 The oral restoration fatigue testing machine shown includes a left side plate 1 and a right side plate 2 which are arranged oppositely, and a fixed bottom plate 3 and a movable bottom plate 3 are respectively arranged at the bottom and the middle of the area between the left side plate 1 and the right side plate 2. The prosthesis test piece platen 4 that moves vertically up and down reciprocatingly, on the sample platen 4, there are two rows of prosthetic test piece mounts 5 evenly arranged in the shape of “one”. An elastic expansion mechanism 7 driven by an eccentric wheel mechanism is provided above the body test piece mounting seat 5, and an elastic telescopic mechanism 7 corresponding to the prosthesis test piece mounting seat 5 is provided at the bottom end of the elastic expansion mechanism 7. The punch 8 w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com