Automatic test system and test method for testing surface capillary water absorption of concrete

An automatic testing system and concrete surface technology, applied in the direction of using material absorption and weighing, can solve the problems of low test sensitivity, accidental error, continuous measurement, etc., to achieve high measurement accuracy, improve sensitivity, and avoid water evaporation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

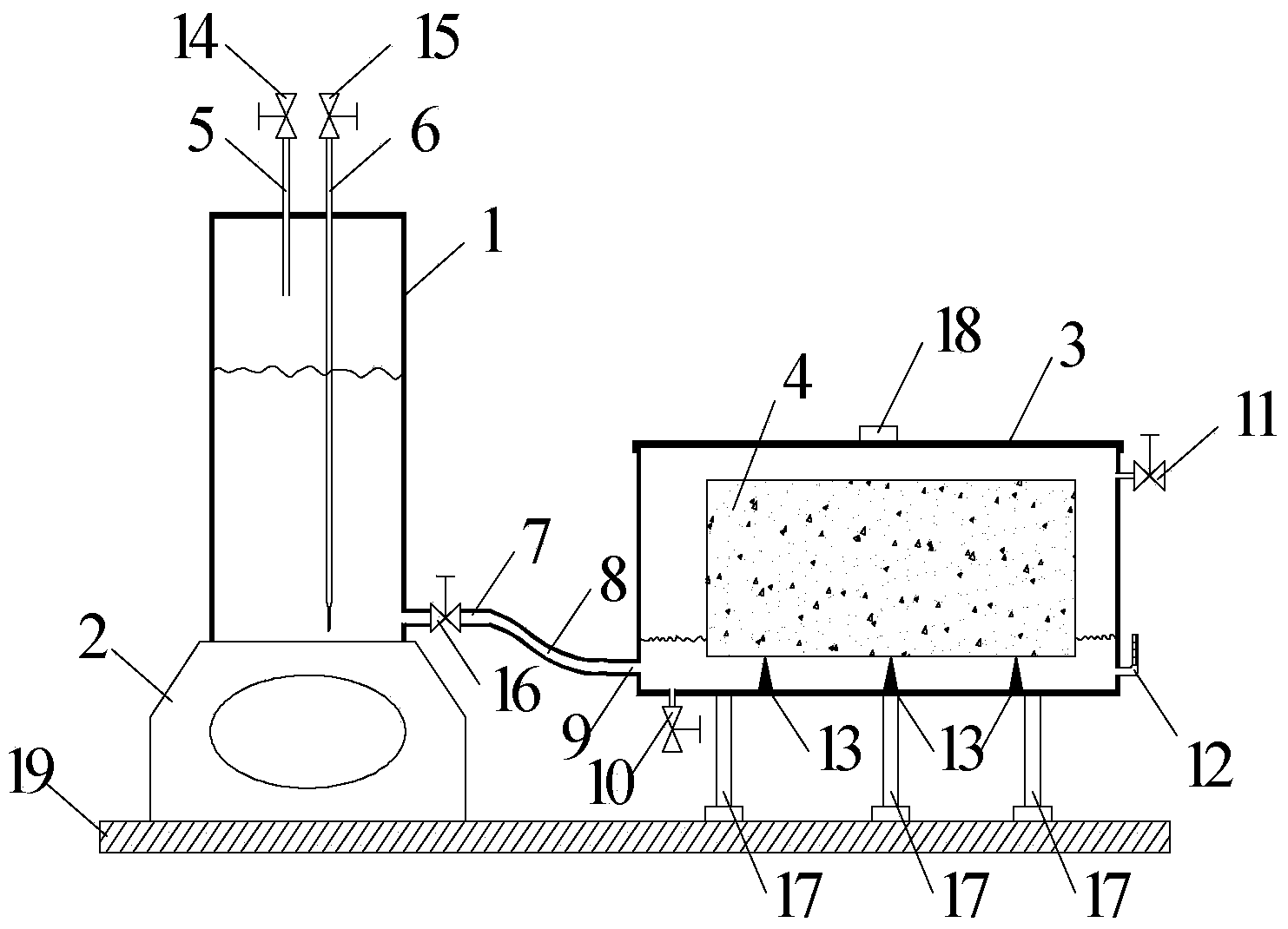

[0021] Specific embodiment one: a kind of concrete surface capillary water absorption automatic test system of this embodiment is made up of constant pressure water supply unit, electronic balance 2 and specimen water absorption unit, constant pressure water supply unit and specimen water absorption unit pass water outlet pipe 7, silica gel The hose 8 communicates with the water inlet pipe 9;

[0022]The constant pressure water supply unit is composed of a constant pressure water supply sealed bottle 1, a gas communication pipe 5, a balance inlet pipe 6 and a water outlet pipe 7; the electronic balance 2 is arranged at the bottom of the constant pressure water supply sealed bottle 1 and is used to measure the The weight of the pressure water supply unit; wherein, the gas communication pipe 5 and the balance air intake pipe 6 are all arranged on the upper end of the constant pressure water supply sealed bottle 1, and the end of the gas communication pipe 5 inside the constant pr...

specific Embodiment approach 2

[0028] Embodiment 2: This embodiment differs from Embodiment 1 in that: the specimen water absorption unit also includes height adjustment feet 17 and a level 18 . Others are the same as in the first embodiment.

specific Embodiment approach 3

[0029] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that three equal-height height-adjusting feet 17 are arranged outside the sample sealing chamber 3 and are located on a horizontal operating platform 19 . Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com