Method for predicting pyrolysis process of environment-friendly flame-retarding asphalt

An environmentally friendly, bituminous technology, applied in the field of asphalt pavement flame retardant, can solve the problems of lack of scientific theoretical basis, poor prediction accuracy of asphalt material pyrolysis process, etc., and achieve the effect of high sensitivity and simple operation

Inactive Publication Date: 2013-12-25

NANJING FORESTRY UNIV

View PDF2 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0013] The purpose of the present invention is to provide a method for predicting the pyrolysis process of environmentally friendly flame-retardant asphalt, which uses a thermal analysis kinetic model to predict the pyrolysis process of environmentally friendly flame-retarda

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

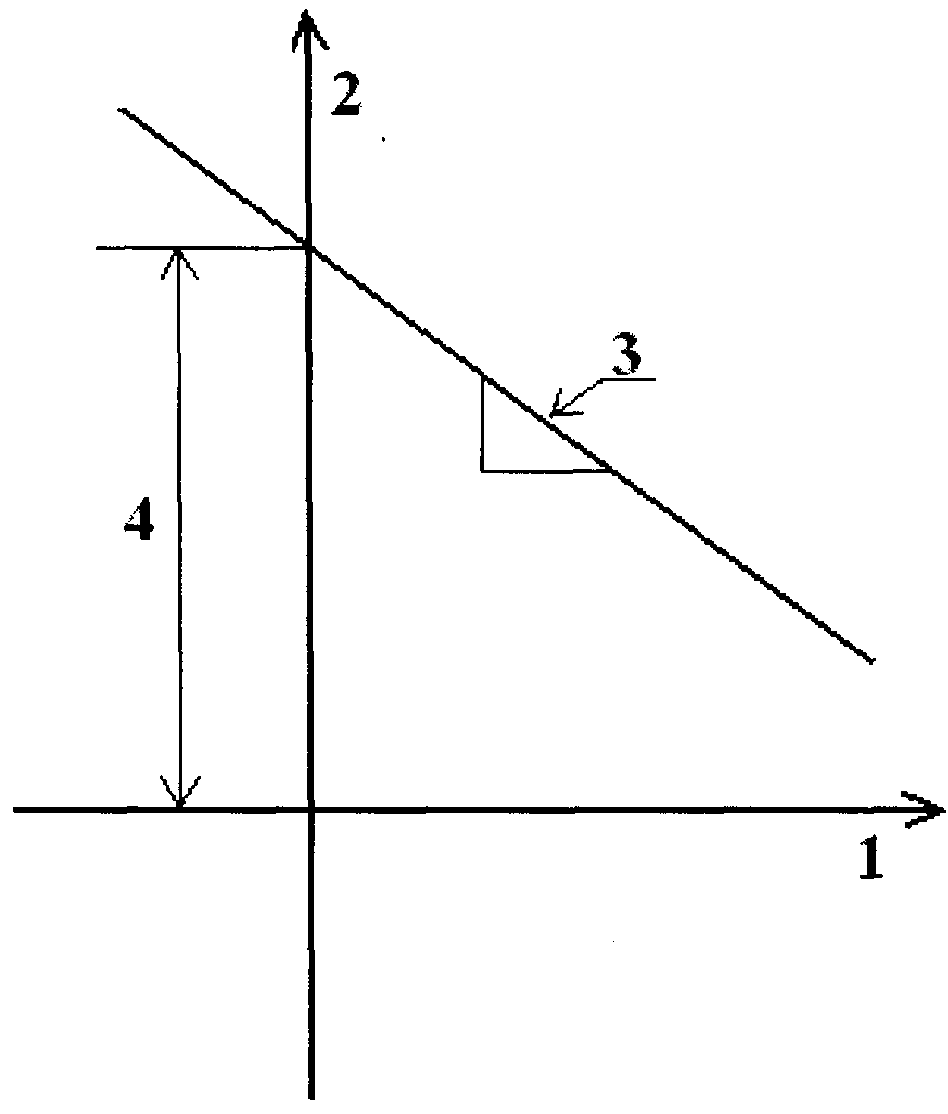

The invention discloses a method for predicting a pyrolysis process of environment-friendly flame-retarding asphalt, belongs to the technical field of flame retarding of asphalt pavements, and solves the problems of low prediction accuracy in the pyrolysis process of an asphalt material and lack of scientific theoretical basis in the prior art. By virtue of the method, the pyrolysis behavior of the environment-friendly flame-retarding asphalt in a high-temperature environment can be deeply revealed. The method comprises the following steps: adding an environment-friendly flame retardant magnesium hydroxide in hot asphalt according to a certain proportion; fully stirring to prepare a uniform and stable flame-retarding asphalt sample; performing test through a thermogravimetric analyzer to acquire data such as a thermogravimetry-derivative thermogravimetry (TG-DTG) curve and char yield; performing optimization and identification through a reaction mechanism according to a thermal analysis kinetic theory, determining a flame-retarding asphalt pyrolysis reaction mechanism function and a conversion rate function to work out pyrolysis kinetic parameters of a flame-retarding asphalt material, namely activation energy and pre-exponential factors; establishing a flame-retarding asphalt pyrolysis model with certain flame retardant mixing amount to obtain a flame-retarding asphalt pyrolysis TG curve through the model so as to predict an asphalt pyrolysis process.

Description

technical field [0001] The invention is a new method for predicting the pyrolysis process of environment-friendly flame-retardant asphalt, which belongs to the technical field of flame-retardant asphalt pavement. Background technique [0002] Asphalt pavement has become the main type of pavement for highway tunnels and large urban underground passages because of its advantages such as comfortable driving, good anti-skid performance, low noise, short construction period, and convenient maintenance. However, asphalt will thermally decompose and burn in a tunnel fire environment, and release a large amount of toxic smoke and heat, which seriously hinders tunnel traffic, brings great difficulties to the escape of trapped people and fire rescue, and causes a large number of casualties. Therefore, it is increasingly urgent to investigate the pyrolysis process and flame retardancy of asphalt materials in high temperature environments. [0003] The hazards of asphalt pavement in th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N5/04

Inventor 许涛王宏畅李强黄凯健马翔

Owner NANJING FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com