Cold chain monitoring instrument and cold chain monitoring method

A monitor and cold chain technology, applied in the measurement of color/spectral characteristics, thermometers that give average/integral values, etc. problems, to achieve the effect of being conducive to standardization, low price, simple structure and production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

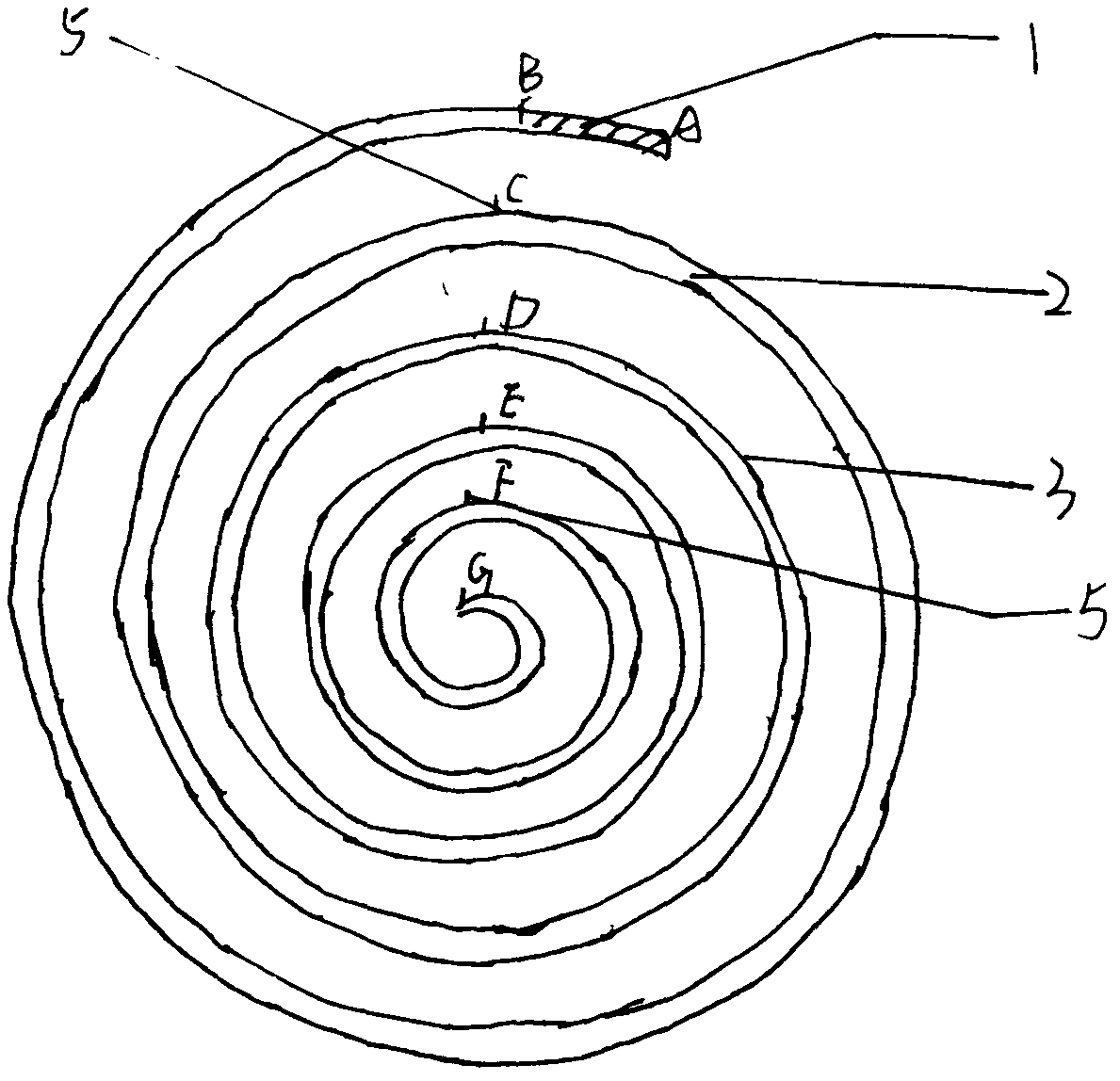

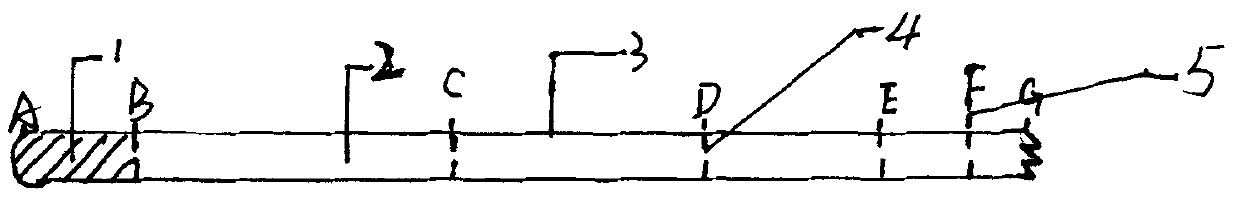

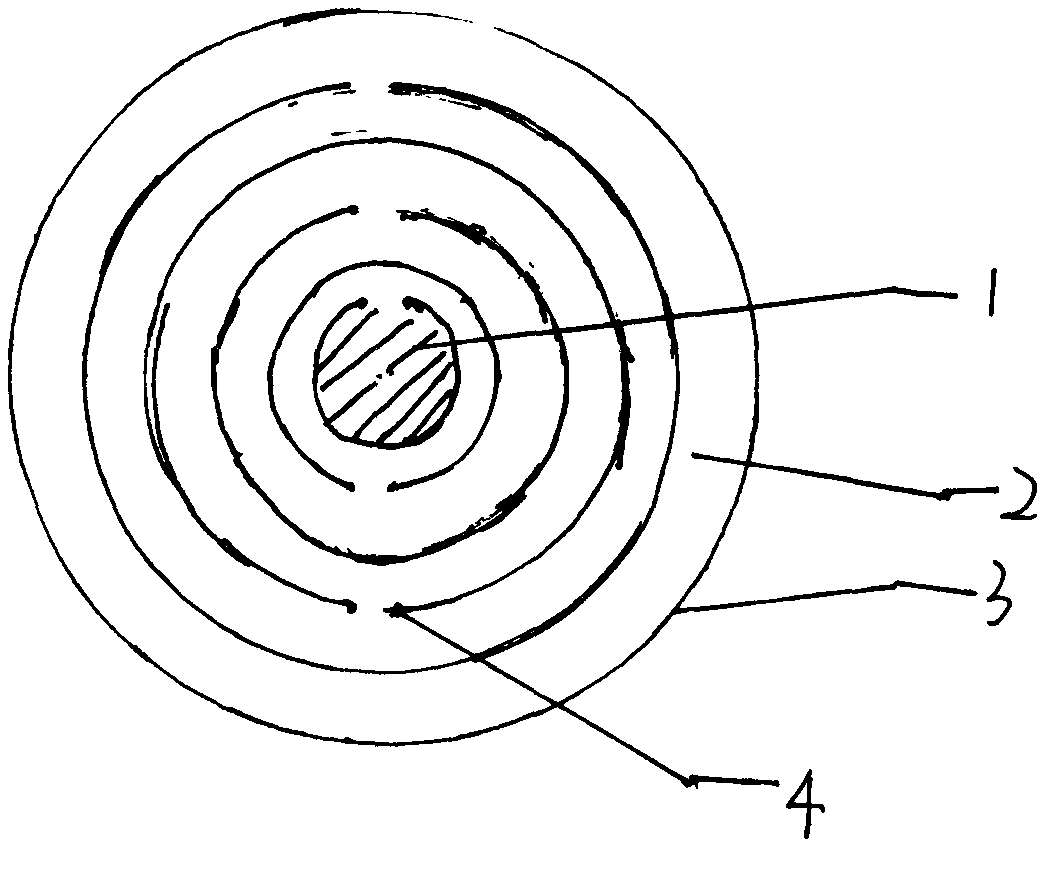

Image

Examples

Embodiment Construction

[0019] The temperature supervision limit for storing cold chain product types determines the selection of the melting point or melting range (melting range) of the dispersant, and then determines the dispersant. You can choose water-soluble pigments. If the pasteurized milk is stored at a temperature lower than 4°C to 5°C, the dispersant can be selected from peanut oil or blended oil corresponding to the melting point or melting range (melting range), and the dispersant can be selected from fat-soluble pigments. The selection of dispersants and dispersants for inactivated vaccines, meat, fruits and vegetables, delicacies, etc. should also be based on the temperature at which the product is stored, and the type of dispersant should be selected according to the melting point or melting range (melting range) of the dispersant, which is not listed here.

[0020] The following cold chain products take pasteurized milk as an example to illustrate the implementation process and pract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com