Axial flow impeller airfoil design method based on singular point distribution method

A technology of axial flow impeller and airfoil design, which is applied to components, calculations, mechanical equipment, etc. of pumping devices for elastic fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

[0047] Axial flow impeller airfoil design method based on singular point distribution method, which includes the following steps:

[0048] S1: Calculate the basic geometry and flow parameters of the whole and each flow surface;

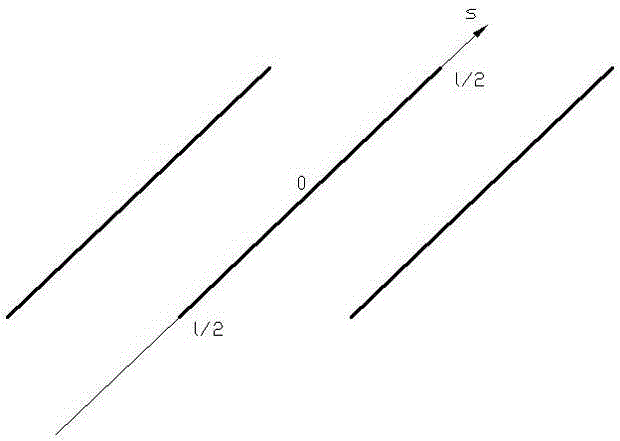

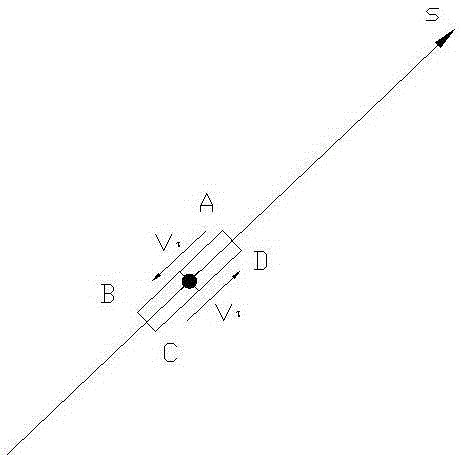

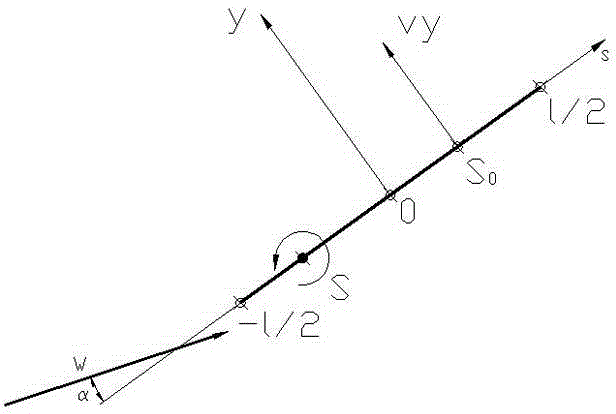

[0049] S2: Calculate the component velocity and the position of the bone line node on the basic airfoil bone line node of each flow surface;

[0050] S3: complete the calculation of bone lines on all flow surfaces in a loop, and the program ends.

[0051] Further, step S1 includes the following sub-steps:

[0052] S101: Determine the number of flow surfaces to be calculated;

[0053] S102: Circularly calculate the radius of each flow surface, calculate the cascade density l / t, grid pitch t and chord length l of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com