A left engine suspension assembly

A left mount and engine technology, applied in the direction of power plant, jet propulsion device, internal combustion propulsion device, etc., can solve the problems of poor shock absorption effect, poor precision guarantee, poor NVH performance, etc., to improve NVH performance and ensure Structural strength, the effect of increasing structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In the following, the present invention will be further explained through the embodiments and the accompanying drawings:

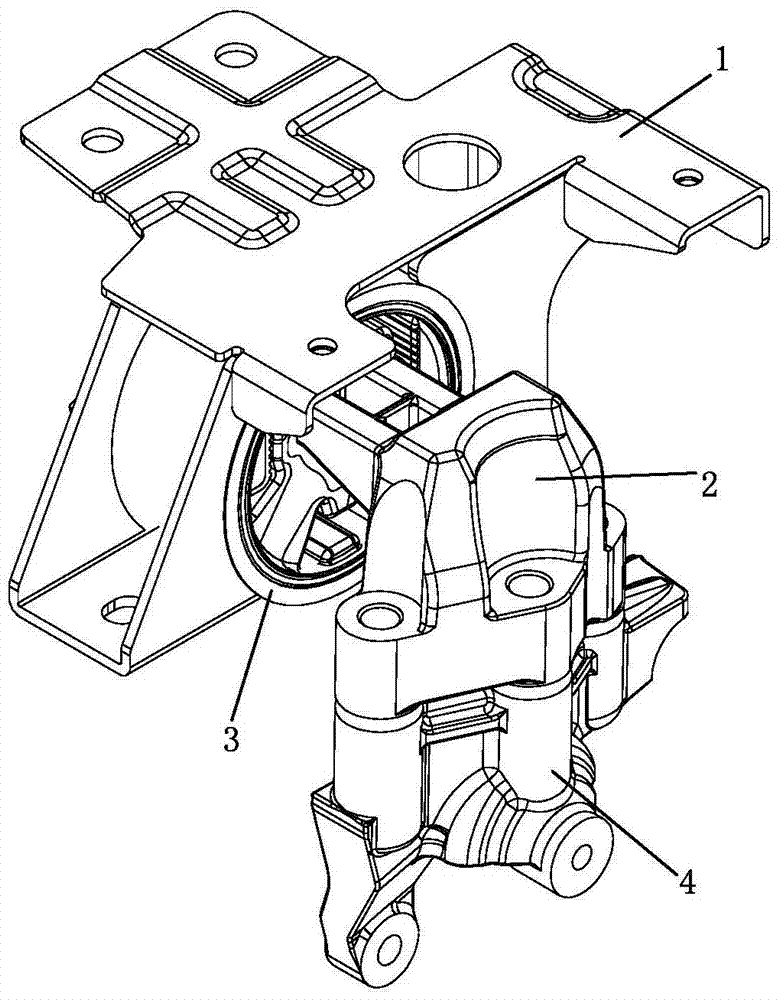

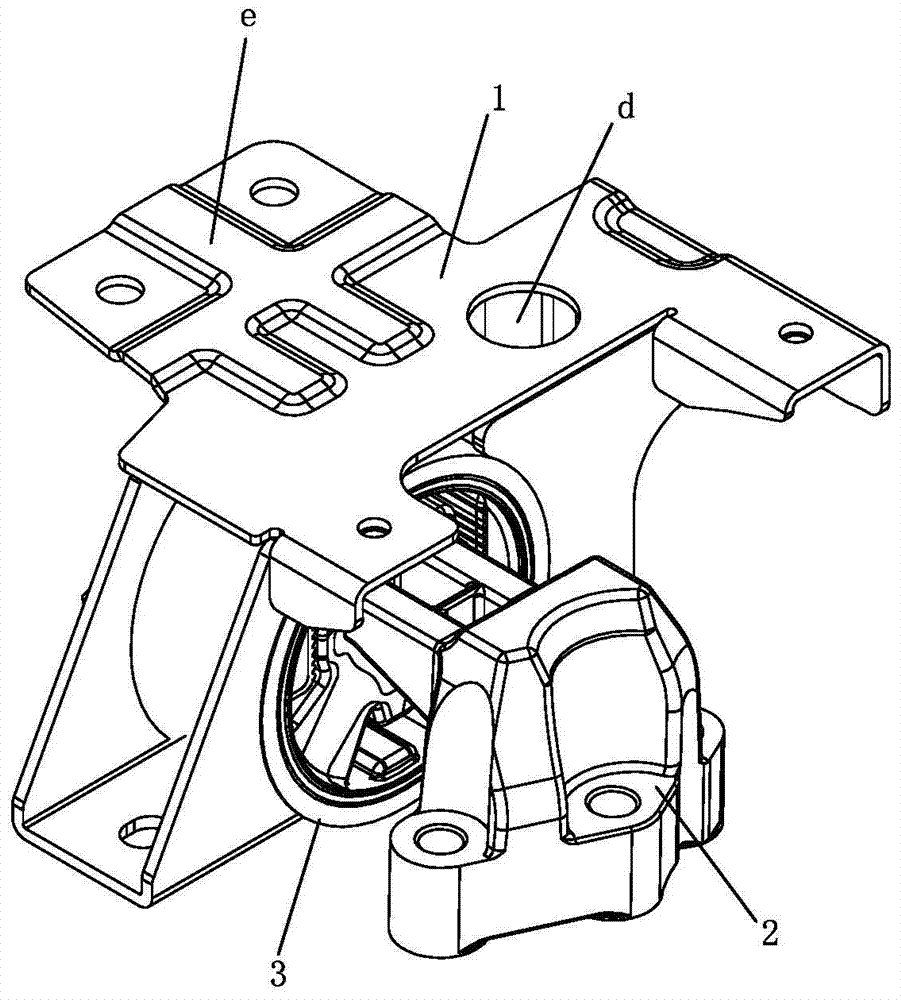

[0022] Such as figure 1 As shown, an engine left suspension assembly is composed of two parts, a left suspension and a left suspension bracket 4. The left suspension is composed of three parts: the body connecting frame 1, the support arm 2, and the rubber bushing 3.

[0023] Combine figure 2 — Figure 5 As shown, the left suspension is connected to the vehicle body by the body connection frame 1, the support arm 2 is used to connect to the left suspension support 4, and the rubber bushing 3 is connected between the vehicle body connection frame 1 and the support arm 2.

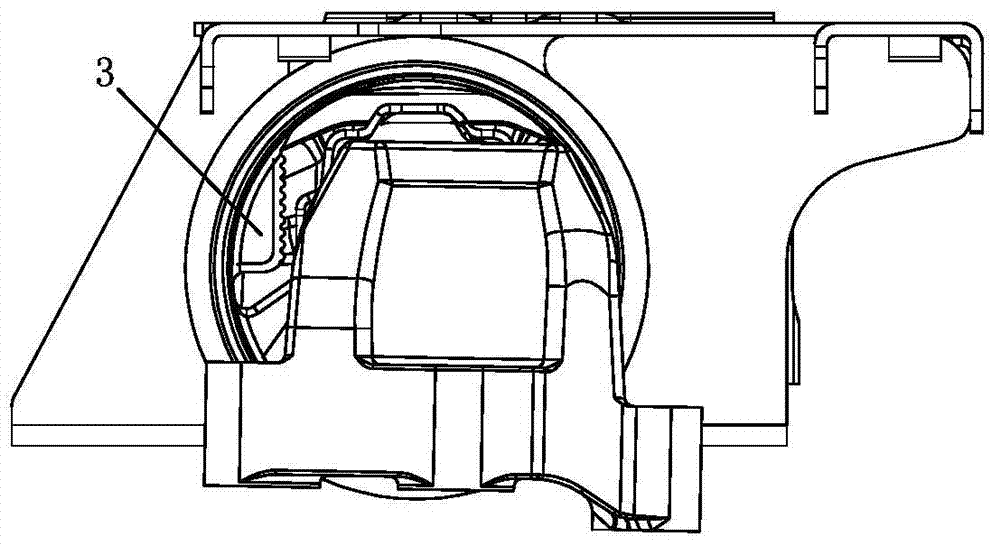

[0024] Combine figure 2 , Image 6 As shown, the rubber bushing 3 is mainly composed of an annular shell 31, a metal core 32, a first rubber 33, and a second rubber 34. Both the first rubber 33 and the second rubber 34 are vulcanized rubber. The metal core 32 has an inner hole for mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com