Powertrain with left, right and rear suspension components

A powertrain and rear mount technology, applied in power units, vehicle components, jet propulsion units, etc., can solve problems such as inability to decouple engine vibration, engine jitter, and high noise, and achieve improved NVH performance and overall strength. , the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

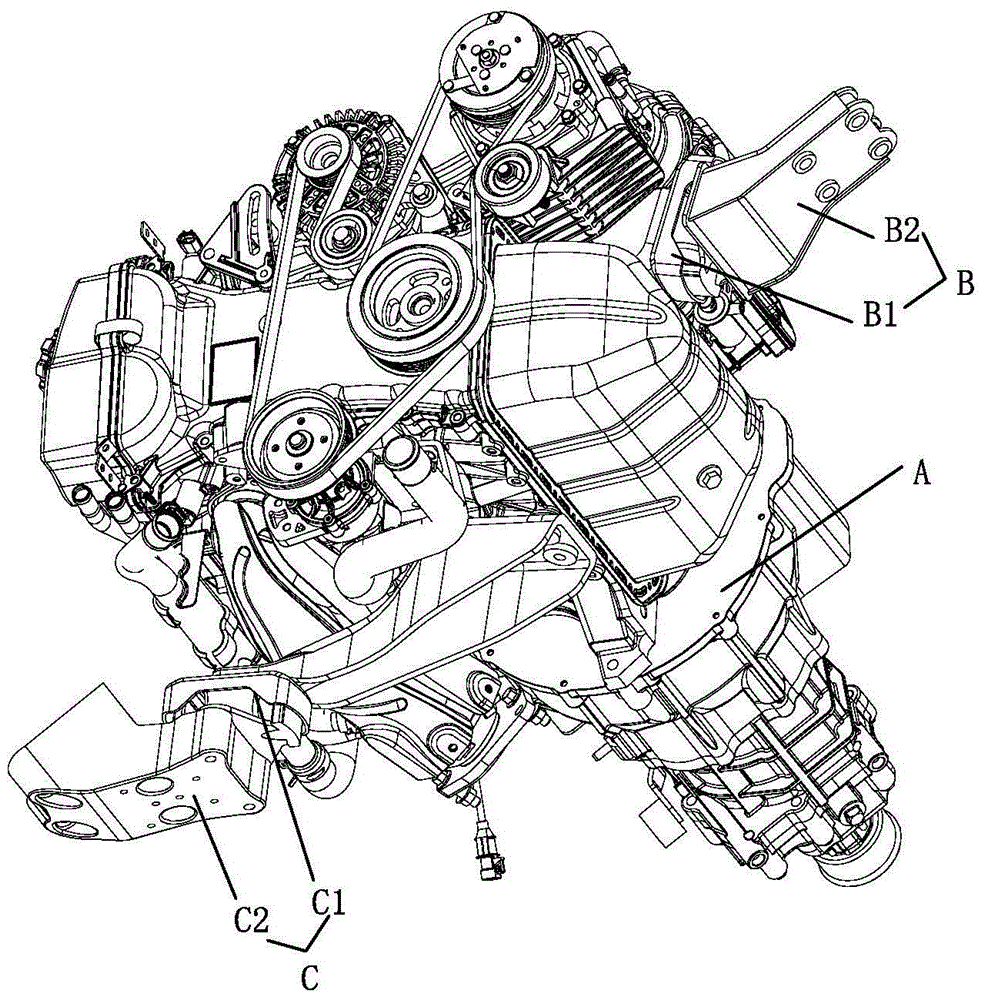

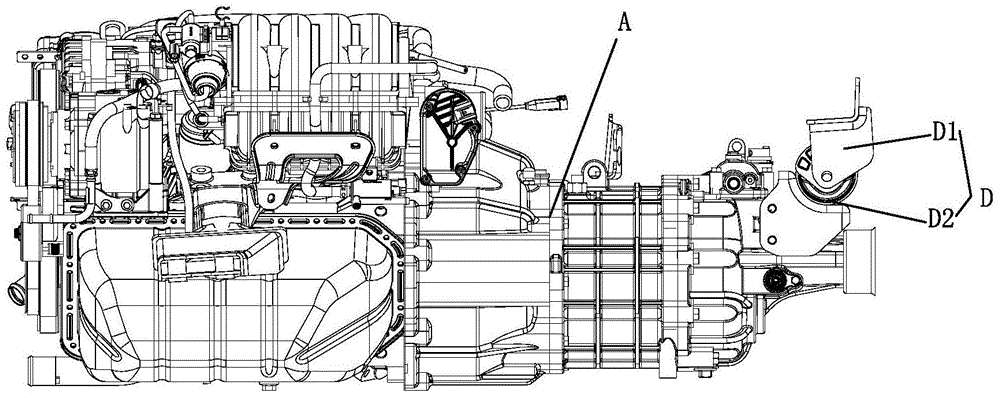

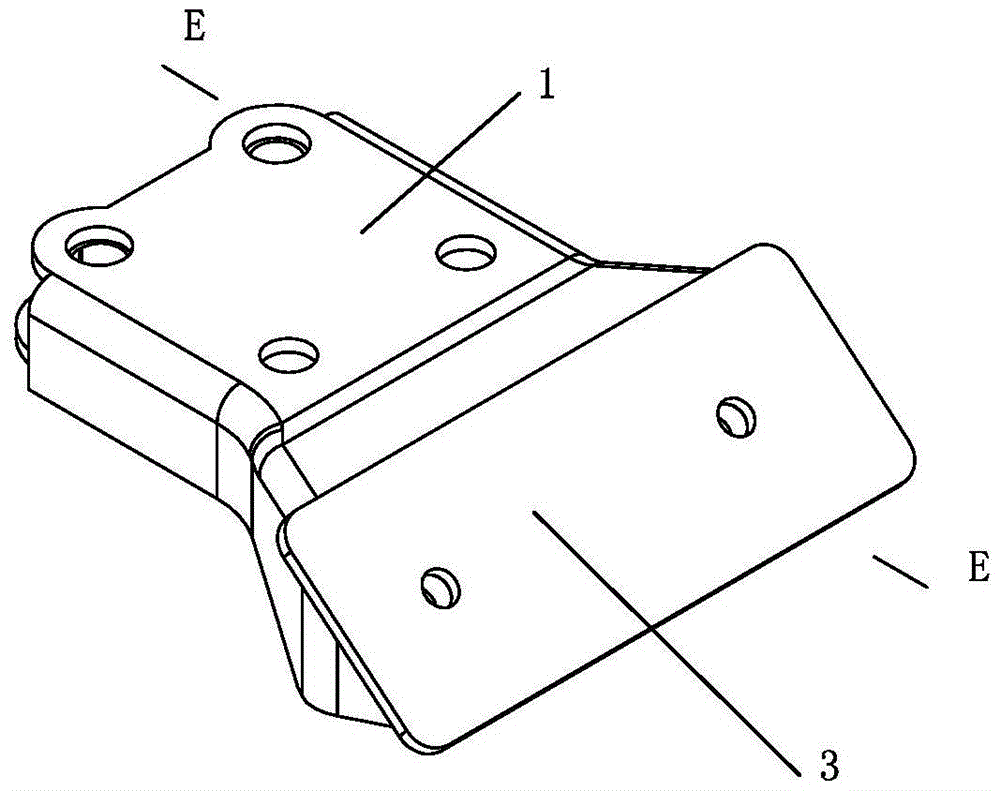

[0026] combine figure 1 , figure 2 As shown, the powertrain with left, right and rear suspension components is composed of powertrain A, left suspension component B, right suspension component C and rear suspension component D arranged on the powertrain. The left suspension assembly B is installed on the left side of the powertrain A, the right suspension assembly C is installed on the right side of the powertrain A, and the rear suspension assembly D is installed behind the powertrain A, respectively as powertrain A Left, right and rear mounting points with the frame. The powertrain A is composed of the engine and the transmission. The left suspension assembly B and the right suspension assembly C are installed on the engine, and the rear suspension assembly D is installed on the transmission. The left suspension assembly B is mainly composed of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com